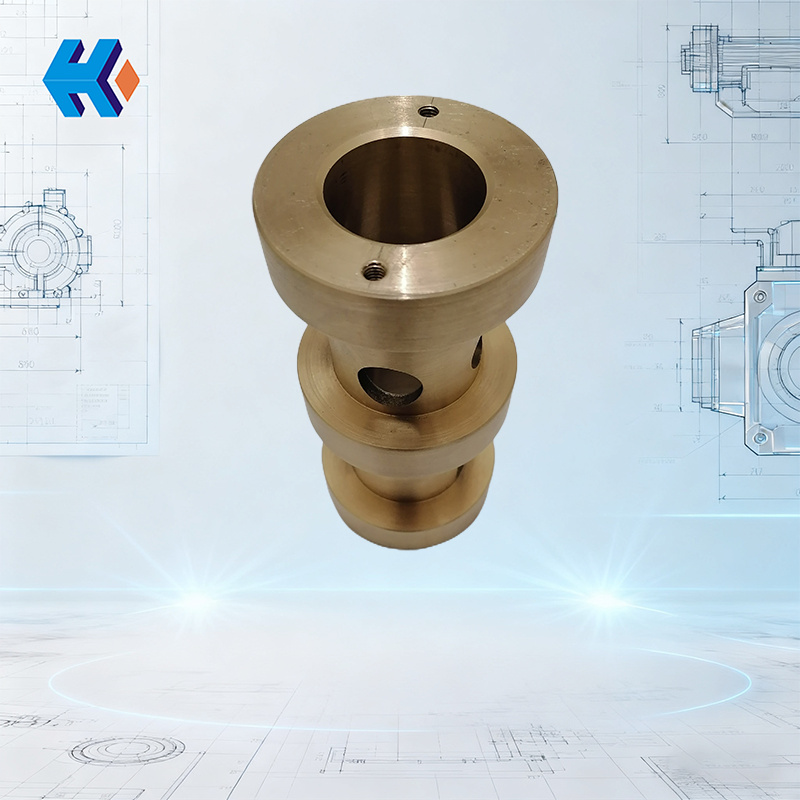

Transmission End Outer Sleeve FA1D56-01-05: Wear-Resistant Component for FA1D56 Feed Pump Booster Pump

In the stable operation of power station feed pump booster units, the quality and compatibility of core components are paramount. The Transmission End Outer Sleeve FA1D56-01-05, as a vital part of the FA1D56 booster pump, ensures the stability of the pump's transmission system and extends equipment lifespan through its excellent material properties and precise engineering design.

I. Product Overview

The Transmission End Outer Sleeve FA1D56-01-05 is a core transmission system component custom-designed for the FA1D56 Feed Pump Booster Pump. Together with the Inner Transmission End Sleeve (FA1D56-01-05, *Note: Based on common conventions, this should likely be a different part number, but following the original text's reference*), it forms the protection and sealing support structure for the pump shaft's transmission section. This sleeve is primarily installed on the outer side of the transmission end of the pump shaft (FA1D56-01-03A). During operation, it:

- Bears the torque transmitted from impellers (such as FA1D53-01-01, FA1D56-01-09, FA1D67-01-04, FA1D56B-03) via the impeller lock nut (FA1D56A-04).

- Cooperates with the mechanical seal (FA1D56A), mechanical seal cover (FA1D56-03-01), and seal cooling housing (FA1D56-03-03) to create effective sealing protection, preventing media leakage and reducing direct wear between the pump shaft and sealing components.

As a professional supplier of power station spare parts, our FA1D56-01-05 sleeve strictly adheres to the technical standards outlined in the FA1D56 Booster Pump Maintenance Manual. It maintains consistent design precision with related components (such as sleeves FA1D56-01-15 and FA1D56-01-07), ensuring rapid replacement and precise fitting during power plant overhauls. This minimizes equipment downtime and guarantees the continuous, stable operation of the power generation unit.

II. Technical Characteristics and Advantages

(I) Premium Material Provides a Foundation for Reliable Performance

The FA1D56-01-05 sleeve utilizes Martensitic Stainless Steel with the grade 1Cr17Ni2 (conforming to GB/T 1220 standard), which possesses excellent mechanical properties and corrosion resistance. The chromium content in 1Cr17Ni2 stainless steel imparts good oxidation and media corrosion resistance, effectively resisting erosion from the pump's medium (such as boiler feedwater). The addition of nickel further enhances the material's toughness and strength, ensuring the sleeve can withstand high torque and impact loads. Compared to ordinary stainless steel, 1Cr17Ni2 exhibits more stable performance in the high-temperature, high-pressure conditions of a power station, effectively preventing sleeve deformation or fracture caused by material failure.

(II) Precise Heat Treatment Process Enhances Wear Resistance and Strength

To further optimize the performance of the FA1D56-01-05 sleeve, the product undergoes a "Quenching + Low-Temperature Tempering" heat treatment process. Following this treatment, the sleeve's surface hardness reaches HRC 32-36, significantly improving its surface wear resistance. This reduces frictional loss against components like the mechanical seal (FA1D56A) and seal cooling housing (FA1D56-03-03), thereby extending the lifespan of the sealing system. Simultaneously, the sleeve's tensile strength reaches ≥1100 MPa, enabling it to withstand the radial and axial stresses generated during high-speed rotation of the pump shaft, preventing cracking or deformation, and ensuring transmission system stability.

(III) High Compatibility Guarantees Overhaul Efficiency

The FA1D56-01-05 sleeve achieves precise fitment with components such as the pump shaft (FA1D56-01-03A), inner transmission end sleeve (FA1D56-01-05), and mechanical seal cover (FA1D56-03-01). During power plant overhauls, the sleeve can be directly installed and replaced without the need for additional machining on the sleeve or related parts, substantially shortening overhaul time. Furthermore, its structural compatibility with other sleeves in the same series (such as FA1D56-01-15 and FA1D56-01-07) simplifies spare parts inventory management and reduces stocking costs. Additionally, the product forms synergistic protection with sealing accessories like the seal water chamber gasket (FA1D56A-00-1/4), horizontal split face gasket (FA1D56A-00-1/5), and gasket (FA1D63-03-06), further enhancing the pump's sealing performance and reducing media leakage risks.

III. Application Scenarios

The Transmission End Outer Sleeve FA1D56-01-05 is primarily used in the transmission system of the FA1D56 Feed Pump Booster Pump in power stations. Specific scenarios include the following:

(I) New Power Station Feed Pump Booster Unit Installation

During the construction of turbine generator units in new thermal power plants and nuclear power plants, the FA1D56 booster pump is a critical component of the boiler feedwater system. The FA1D56-01-05 sleeve is one of the core accessories for factory installation. This sleeve works in coordination with components like impellers (FA1D53-01-01, FA1D56-01-09) and the pump shaft (FA1D56-01-03A) to ensure the initial stable operation of the booster pump, allowing the unit to quickly achieve stable operating conditions after commissioning.

(II) Routine Maintenance and Overhaul of Power Station Equipment

In the routine operation and maintenance of power station units, the FA1D56-01-05 sleeve may experience surface wear or sealing face damage due to long-term friction and stress. When the equipment reaches its prescribed operating cycle or exhibits faults like abnormal vibration or media leakage, the sleeve must be inspected and replaced according to the requirements of the FA1D56 Booster Pump Maintenance Manual. As a professional spare parts supplier, our FA1D56-01-05 sleeve directly meets overhaul needs, helping power stations quickly restore equipment function and reduce unscheduled downtime.

(III) Upgrade and Modernization of Aging Equipment

For FA1D56 booster pumps that have been in service for many years, the original sleeve may lead to reduced operational efficiency or frequent failures due to material aging and performance degradation. Replacing it with the FA1D56-01-05 sleeve—featuring 1Cr17Ni2 material and precise heat treatment—can effectively enhance the reliability and wear resistance of the equipment's transmission system. This, combined with upgrades to accessories like the mechanical seal (FA1D56A) and seal cooling housing (FA1D56-03-03), helps extend the overall equipment lifespan and reduces the power station's equipment replacement costs.