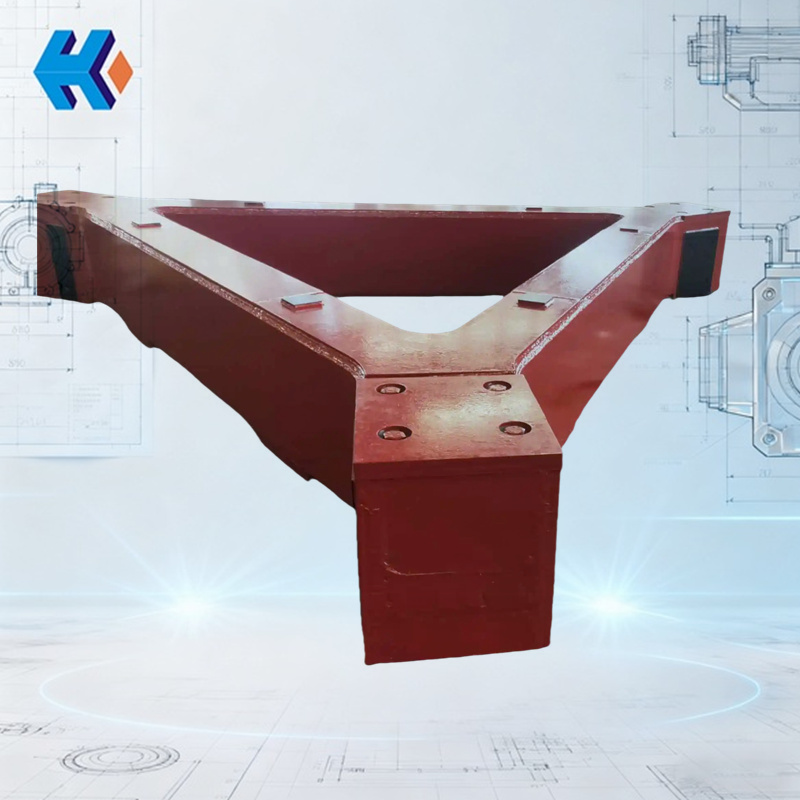

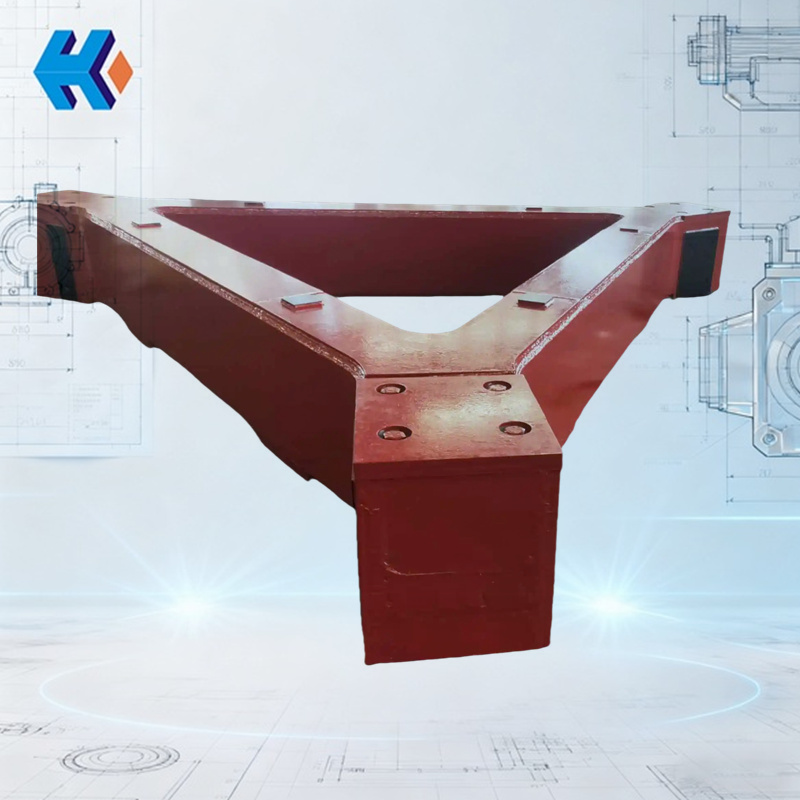

Vertical Roller Mill (VRM) Press Frame 43MG20.11.10 Fatigue Damage: Early Signals and Preventive Strategies

The VRM Press Frame 43MG20.11.10 functions like a three-point support bracket in coal mills. Stability requires uniform force distribution across all supports. If one side strains while others idle, the bracket becomes unstable, leading to fatigue fractures.

I. Symptoms of a Distressed Press Frame

Operational details often reveal structural distress before a failure occurs. Watch for these 4 signals:

Uneven loading causes vibration to jump. A spike from 0.1 mm/s to 0.2 mm/s often indicates a worn guide block on one side, forcing the frame to work at an angle.

Diagnostic SignStress concentrates at the trunnion roots, flange welds of the tension rod, and areas near the guide blocks. Detecting a 5mm crack during an overhaul can prevent a catastrophic frame snap.

Visual Inspection FocusWhen the frame is misaligned, rollers grind fiercely in some spots and minimally in others, producing coal powder with inconsistent fineness and large particles.

If M36 main bolts are loosening or snapping, it is rarely a bolt quality issue—it is usually long-term stress from uneven frame loading.

II. Case Study: Guide Gap Mismanagement

A ZGM123G-II mill experienced severe vibration and a broken tension rod (300MG41.11.13G). Inspection found the guide clearance was significantly out of spec. This instability forced the 43MG20.11.10 frame to bear loads at an angle, causing three large cracks at the trunnions.

Correction: Technicians now check clearance with feeler gauges at every shutdown and installed vibration sensors on the trunnions. The frame has since run 12,000+ hours error-free.

III. 4 Steps to Minimize Failure

1. Real-Time Load Tracking

Install stress sensors on the three trunnions. System alerts should trigger if the load difference between any two rollers exceeds 5%.

2. Maintenance of Guiding Systems

Promptly replace worn guide blocks (300MG41.11.12.07) and coat surfaces with Molybdenum Disulfide lubricant.

3. Simultaneous Roller Replacement

Replace all three rollers (MG23.23.11.0) as a set from the same batch. Ensure planarity error does not exceed 3mm.

4. Life Cycle Monitoring

Input operating hours and vibration peaks into a life cycle table. At 80% of design life, prioritize hard-facing or reinforcement of susceptible areas.

HKZX-2025-10-31