Vertical Roller Mill (VRM) Press Frame 43MG20.11.10 Fatigue Damage: Early Signals and Preventive Strategies

Vertical Roller Mill (VRM) Press Frame 43MG20.11.10 Fatigue Damage: Early Signals and Preventive Strategies

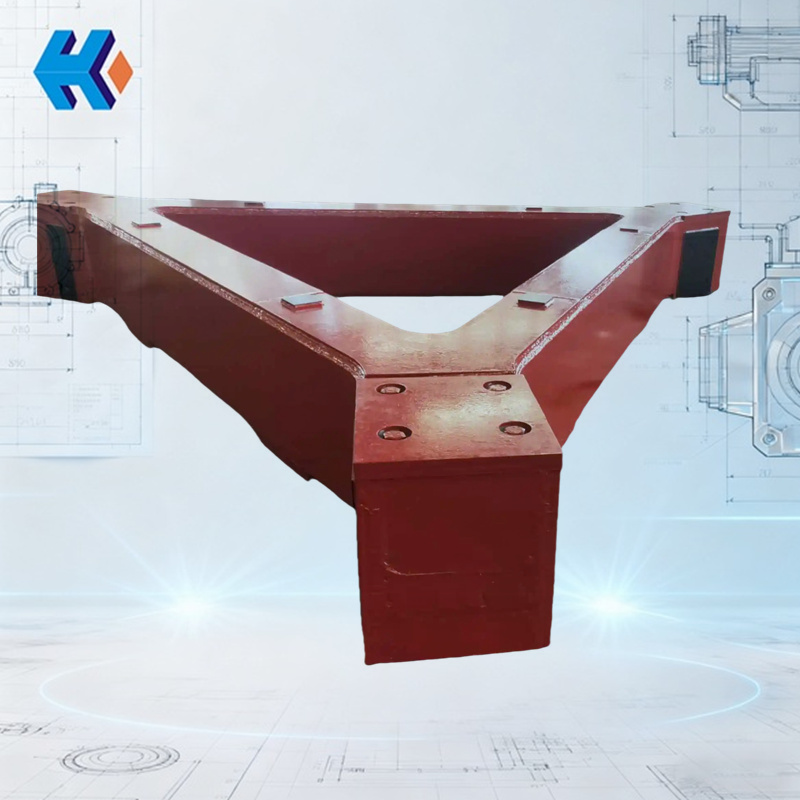

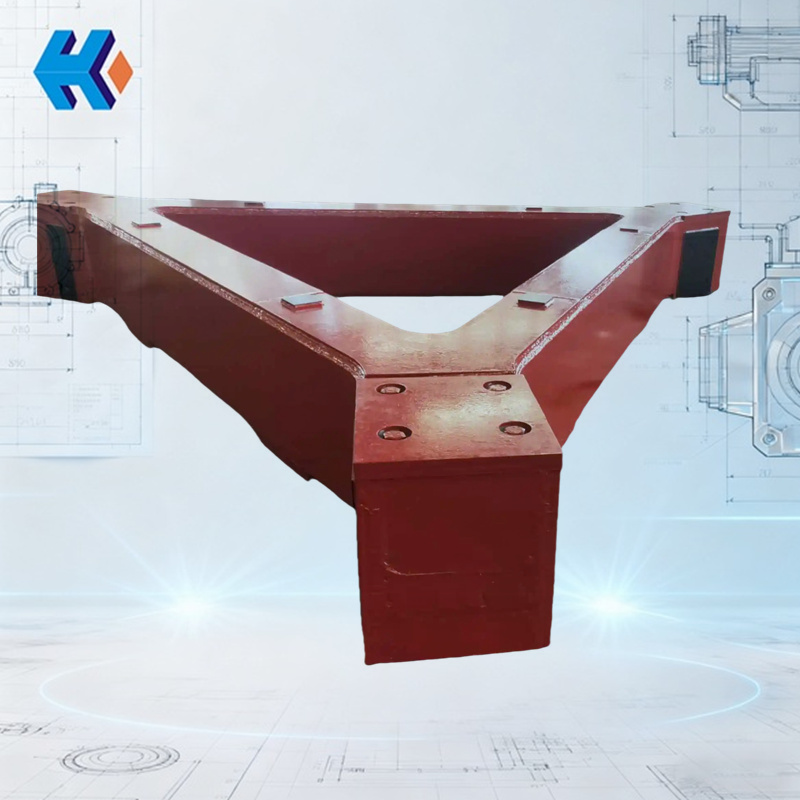

The VRM Press Frame (43MG20.11.10) functions like a three-point support bracket: one side connects to the heavy load (loading tension rod), and the other three sides support the grinding rollers. Stability requires uniform force distribution across all three supports. If one side strains while the others idle, the bracket will quickly become unstable, possibly fracturing.

Drawing on practical experience from dozens of power plants nationwide, this article discusses the early signals of uneven loading and fatigue damage in the press frame, along with proactive strategies to prevent these problems.

I. Obvious Symptoms of a Distressed Press Frame

You don't need complex blueprints to spot trouble; everyday operational details reveal issues. Here are 4 common symptoms:

- Sudden, Severe Vibration in the Pulverizer (ZGM-123G)

Normally, VRM vibration is minimal, comparable to a running household fan. However, uneven press frame loading causes vibration to spike suddenly. You can distinctly feel the machine shaking, sometimes hearing loud banging. Example: At a thermal power plant, the vibration value jumped from a normal 0.1 mm/s to 0.2 mm/s .Inspection revealed a severely worn support shoe (guide block) on one side of the press frame, causing it to work at an angle.

- Small Cracks Appearing on the Press Frame (43MG20.11.10)

Just as a person carrying a load on one arm suffers shoulder pain or injury, uneven loading causes extreme stress in certain areas of the press frame, leading to cracks. These cracks typically occur in three locations:

-

- The root of the small connecting lugs (trunnions) for the grinding rollers.

- The welded joint (flange weld) connecting the tension rod.

- The area near the guide blocks that contact the mill casing.

Example: During an overhaul, a5 crack was found at the trunnion root of a press frame. A delayed detection could have resulted in a catastrophic failure of the entire frame.

- Uneven Wear on Grinding Rollers (29MG63.11.09) and Coarsening of Coal Powder

Uneven loading causes the grinding rollers to function like a misaligned millstone, grinding fiercely in some spots and minimally in others. the resulting pulverized coal will have inconsistent fineness, including large particles. Example: At a chemical plant, recurring pipeline blockages were traced back to uneven press frame loading, which caused the rollers to wear unevenly, leading to a mix of overly coarse and fine coal powder.

- Loose or Broken Connecting Bolts (200MG41.11.09.77)

The bolts on the press frame are like shoelaces—they must be tight for stability. Uneven loading exacerbates machine vibration, which loosens the bolts, sometimes snapping them entirely. Example: The most alarming incident involved a broken M36 main bolt (thicker than a finger) on a power station's pulverizer. Timely discovery prevented the press frame from disintegrating. The cause was determined to be excessive long-term stress on the bolt due to uneven loading on one side of the press frame.

II. Case Study: Avoiding Pitfalls and Implementing Corrective Action

Case Study 1: Guide Gap Mismanagement Nearly Scraps the Press Frame (43MG20.11.10)

A thermal power plant's VRM (ZGM123G-II) suddenly vibrated severely, and one loading tension rod (300MG41.11.13G) broke. Upon emergency shutdown and disassembly, technicians found that the guide clearance! This is comparable to a table leg having a large gap with the floor—instability is inevitable.

Why did this happen? The power plant neglected to regularly check this clearance. Small, cumulative wear eventually forced the press frame (43MG20.11.10) to bear the load at a severe angle, resulting in three large cracks in the trunnion root.

Corrective Measures Implemented:

- Regular Measurement: The clearance is now checked with a feeler gauge during every shutdown.

- Condition Monitoring: Vibration sensors were installed on the press frame trunnions, acting as a "thermometer" for the machine.

- Result: Since the modifications, this press frame (43MG20.11.10) has operated for over 12,000 hours without recurrence of the issue.

III. The Secret to Prevention: 4 Steps to Minimize Press Frame Failure

- Install Monitoring for Real-Time Load Tracking

Similar to installing security cameras, stress sensors were placed on the three trunnions of the press frame to monitor the load distribution of the three grinding rollers in real time. The system alerts technicians if the load difference between any two rollers exceeds 5%. Additionally, sealing air pressure is checked hourly to ensure no air leakage into the press frame, which could compromise loading accuracy.

- Conduct Regular Maintenance of the Guiding and Loading Systems

- Guide Clearance: The clearance is checked at every shutdown, worn guide blocks (300MG41.11.12.07) are promptly replaced, and the guide surfaces are regularly coated with a wear-resistant lubricant (e.g., Molybdenum Disulfide) to minimize wear.

- Loading System: The hydraulic valves are adjusted every 3 months to ensure accurate loading force. Accumulator pressure is checked weekly, and bladders are replaced on schedule without delay.

- Adhere to Strict Grinding Roller Replacement Protocols

All three grinding rollers (MG23.23.11.0) must be replaced simultaneously, using components from the same batch with identical precision. After replacement, the clearance between the roller and the grinding ring must be inspected, with a maximum planarity error not exceeding3 During the test run, the vibration difference between the three rollers must not exceed0.05 mm/s to ensure uniform press frame loading.

- Proactive Life Cycle Calculation: Preventative Repair, Not Emergency Fix

A life cycle calculation table was developed based on the press frame material, operating hours, and vibration data. By inputting accumulated hours, vibration peaks, and load differences, the remaining useful life can be estimated. When the component reaches 80% of its designed service life, preparations for replacement or reinforcement are made (e.g., hard-facing a wear-resistant layer on susceptible areas), preventing catastrophic failure.

IV. Summary: Prevention is Cheaper than Repair

Most problems with the VRM Press Frame (43MG20.11.10) are the result of cumulative, uneven loading. Our experience proves that prevention is far more cost-effective than repair. By diligently monitoring vibration, checking clearances, and adhering to strict replacement and maintenance protocols, most potential issues can be intercepted before they lead to failure.

HKZX -2025-10-31