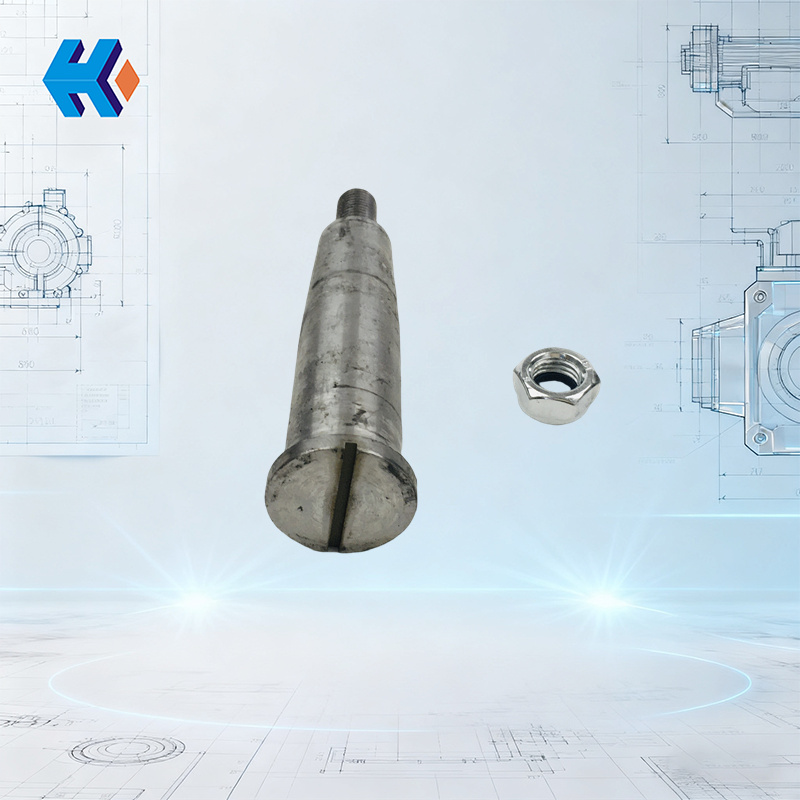

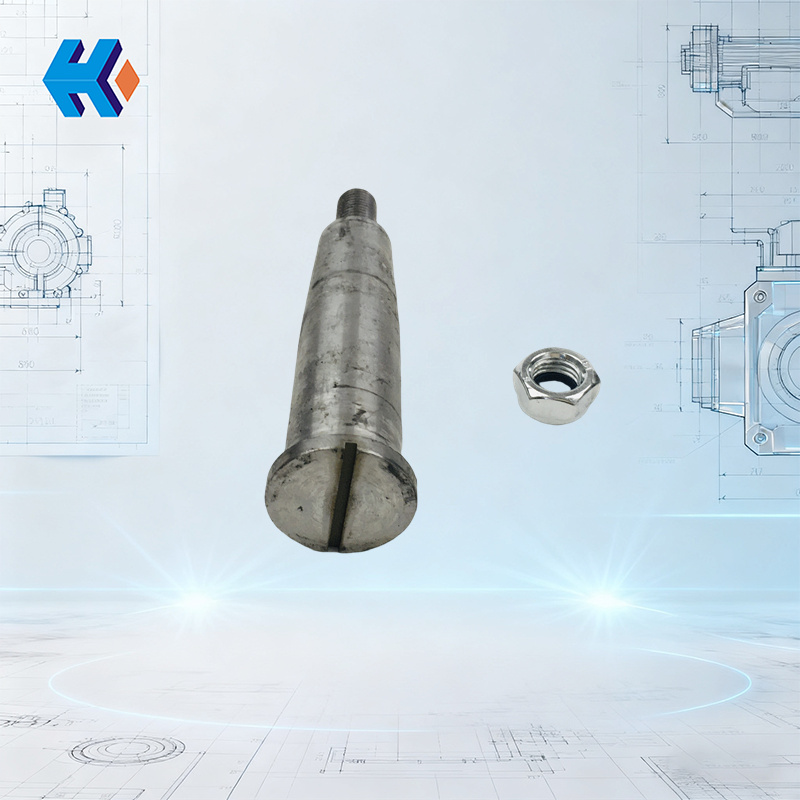

Pin Column 300MG41.11.02.97: The Critical Pivot for Medium-Speed Coal Mills

Pin Column 300MG41.11.02.97: The Critical Pivot for Medium-Speed Coal Mills

The Pin Column 300MG41.11.02.97 is a critical connecting and positioning component specifically designed for medium-speed coal pulverizers, which are core milling equipment in large-scale thermal power plants.

Key Function and Load Transmission

As a "pin column," its central function is to provide precise positioning and reliable load transfer. In a medium-speed coal mill, many components require a hinged connection that allows relative rotation while strictly restricting displacement. A prime example is the mill roller arm, which needs to pivot around an axis to adapt to variations in coal bed thickness.

The Pin Column 300MG41.11.02.97 is the heart of this hinged joint. It passes through the pre-drilled holes of different components, forming the center of rotation and ensuring that all parts follow their designed movement trajectory. Simultaneously, it bears the enormous shear forces, tensile loads, and impact forces generated during the grinding process. It safely transfers these forces from one component to another, making it a pivotal link in the entire mechanical force transmission chain.

Installation and Reliability

During installation, after the pin column is inserted through the connecting components, it is axially secured using matching screws and nuts to prevent it from moving axially or falling out due to vibration during equipment operation. This design ensures a secure and reliable connection, avoiding equipment failure caused by pin displacement.

The screws and nuts typically feature a high-strength grade and may be equipped with anti-loosening washers or thread-locking adhesives to withstand the continuous and intense vibration inherent to coal mill operation.

Material Science and Durability

This pin column must possess extremely high strength, excellent toughness, and superior wear resistance. It is usually manufactured from high-strength alloy steel and undergoes quenching and tempering (Q&T) heat treatment to achieve optimal comprehensive mechanical properties—enabling it to bear immense loads while maintaining impact toughness.

The surface of the part that contacts the shaft bore often requires treatments such as high-frequency induction hardening or carburization to increase surface hardness. This enhances its abrasion resistance, protecting against dimensional loss caused by fretting wear and erosion from coal particles.

Conclusion: A High-Reliability Mechanical Hub

The Pin Column 300MG41.11.02.97 is a key mechanical part that integrates high strength, high precision, and high reliability. Through its accurate dimensional matching, dependable connecting function, and outstanding material properties, it serves as a "critical hub" within the complex mechanical structure of the pulverizer.

In equipment maintenance, stringent inspection of the pin column for wear, cracks, and deformation, and timely replacement of non-conforming parts, are fundamental tasks to ensure the long-term, safe, and efficient operation of this "steel behemoth" known as the coal mill.

More Coal Mills parts we can supply below:

|

Hydraulic Oil Station Hydraulic Reversing Valve |

02MG20.11.19.01 |

|

Grinding Roller Annular Sealing Air Duct |

21MG30.11.23.2 |

|

Roller-Bowl Medium-Speed Coal Mill Anti-Wear Plate |

MG42.11.09.72 |

|

Oil Seal Support Ring |

20MG40.11.09.83 |

|

Roller Frame Roller Bearing Seat |

20MG30.32.99 |

|

MG00.11.19.01 |

|

|

MG00.11.19.01 |

|

|

Protective Cover / Guard |

20MG40.11.09.03 |

|

Protective Cover / Guard |

20MG42.11.09J |

|

Sealing Air Duct |

20MG40.11.12.07 |

HKZX-2025-11-05