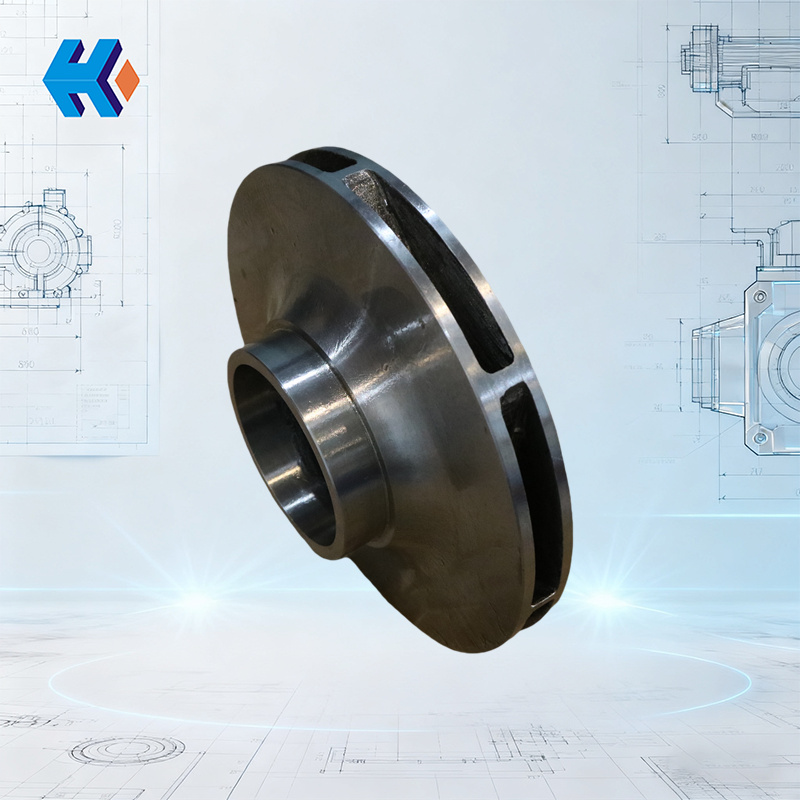

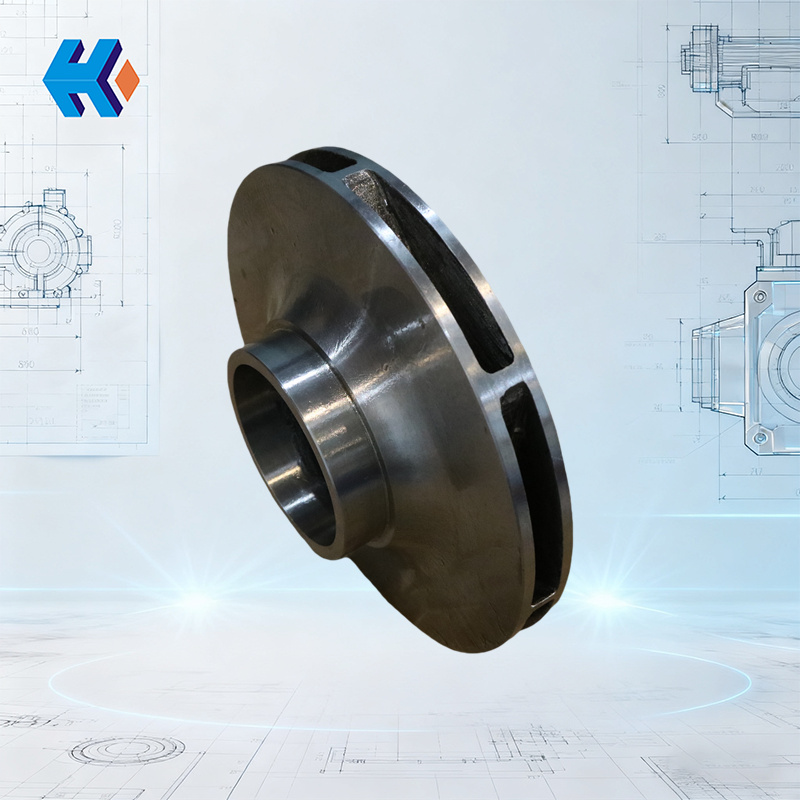

Steam Turbine Main Oil Pump Impeller

I. Equipment Overview

The steam turbine main oil pump impeller is the core rotating component that enables the main oil pump to pressurize and transport oil. It is rigidly connected to the pump shaft with a key and is directly driven by the steam turbine's main shaft (at a rated speed of 3000 r/min). It is installed inside the main oil pump casing. Through high-speed rotation, it generates centrifugal force, converting the low-pressure turbine oil provided by the injector into a high-pressure oil flow. It is the "power source" for the main oil pump to supply oil to the bearings, speed control system, and protection devices.

As a critical component for the main oil pump's energy conversion, the impeller's structural accuracy and material performance directly determine the stability of the oil supply pressure, the flow rate's compliance, and the operating efficiency. It plays a decisive role in the steam turbine unit's lubrication reliability and safety protection functions.

II. Core Functions and Working Principle

1. Core Functions

- Pressurization and Transportation: It converts low-pressure oil (which is positively sucked in by the injector) into high-pressure oil that meets system requirements through high-speed rotation. This ensures the supply of pressure oil for bearing lubrication, the speed control system, and safety protection devices.

- Flow Control: The blade structure design precisely controls the oil output. It adapts to the total demand for lubricating oil (for cooling bearings) and regulating oil (for driving the speed control mechanism) during full-speed operation of the unit.

2. Working Principle

When the impeller rotates at high speed with the pump shaft, the blades drive the oil to move in a circular motion. Under the action of centrifugal force, the oil is thrown out at high speed from the center of the impeller to the edge, forming a high-pressure oil flow and delivering it to the system. At the same time, the center of the impeller forms a negative pressure due to the oil being thrown out, and low-pressure oil is continuously sucked in through the injector. This forms a continuous cycle of "suction-pressurization-output," achieving a stable oil supply from the main oil pump.

III. Structural Characteristics and Material Selection

- Structural Design: Mostly adopts a closed impeller structure, which consists of a hub, blades, a front cover plate, and a rear cover plate. The blades are symmetrically distributed to ensure uniform stress. The flow channel is smooth to reduce oil resistance and ensure stable pressure.

- Material Adaptability: High-strength alloy materials (such as 2Cr13 stainless steel) are selected based on the operating conditions. They have wear resistance, cavitation resistance, and good mechanical strength, and they can withstand the stress impact of turbine oil media and high-speed rotation for a long time.

IV. Overhaul Standards and Quality Requirements

The overhaul of the impeller is a core part of main oil pump maintenance and must strictly adhere to the following standards:

- Appearance Inspection: The surface must not have cracks, cavitation pits (depth ≤0.3mm), rust, or blade deformation. The edges must not be curled or chipped to avoid turbulent oil flow that could cause pressure fluctuations.

- Keyway Fit: The key connection with the pump shaft must meet the following: the fit clearance on both sides of the key and the impeller keyway is 0.02~0.03mm; the upper clearance is 0.35~0.5mm; and the key-to-slot fit tightness is 0~0.01mm. This ensures that power transmission has no looseness.

- Rotor Accuracy: After the impeller is assembled with the pump shaft, the overall rotor runout should be ≤0.03mm, and the concentricity should be ≤0.02mm. This prevents rubbing with the pump casing or abnormal vibration during rotation.

- Cleanliness Requirements: During overhaul, the oil stains and impurities in the flow channel must be thoroughly cleaned to prevent particles from entering the system, which would wear components or block oil passages.

- Replacement Standard: If there are cracks, severe cavitation (pit depth > 0.5mm), or blade deformation, the impeller must be replaced to ensure the oil supply performance meets the standard.

V. Importance and Related Impact

The impeller's performance is directly related to the reliability of the main oil pump:

- If the impeller is worn or imbalanced, it will cause fluctuations in the outlet pressure, affecting the bearing lubrication effect (possibly causing wear) and the response accuracy of the speed control system (causing load fluctuations).

- Impeller failure may lead to an interruption of the oil supply, triggering the unit's protection shutdown. Therefore, its quality is the core prerequisite for ensuring the "independent oil supply" function during full-speed steam turbine operation.

Through strict manufacturing precision control and the implementation of overhaul standards, the impeller can ensure the main oil pump's long-term stable output of high-pressure oil flow, providing critical support for the safe and efficient operation of the steam turbine unit.

VI. Custom Fabrication per Drawings

We provide precision manufacturing of steam turbine main oil pump impellers strictly according to your technical drawings. Our production fully complies with your specified requirements: including material selection, structural design, keyway fit clearances , and rotor accuracy. We also conduct non-destructive testing, cavitation inspection, and dynamic balance testing to ensure each impeller matches your main oil pump's pressure/flow demands, whether for maintenance replacement or new unit assembly.

Keep Your Turbine's Oil Supply Stable—Choose Our Main Oil Pump Impeller!

Our impellers deliver reliable centrifugal pressurization, precise flow control, and long wear resistance. Contact us now for a customized quote, overhaul standard guidance. We guarantee on-time delivery and after-sales support to protect your turbine’s lubrication and safety system.