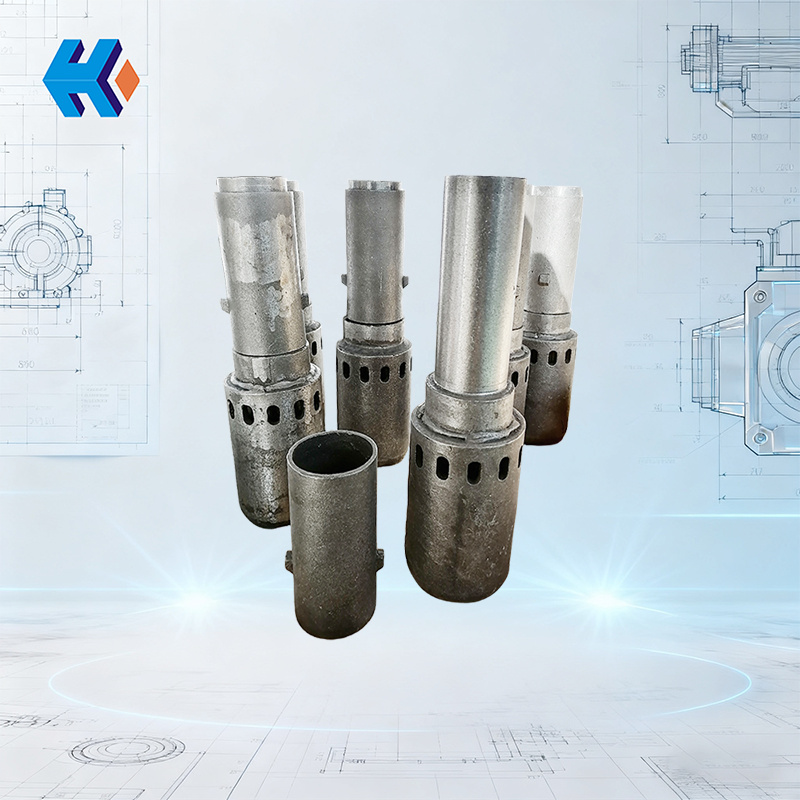

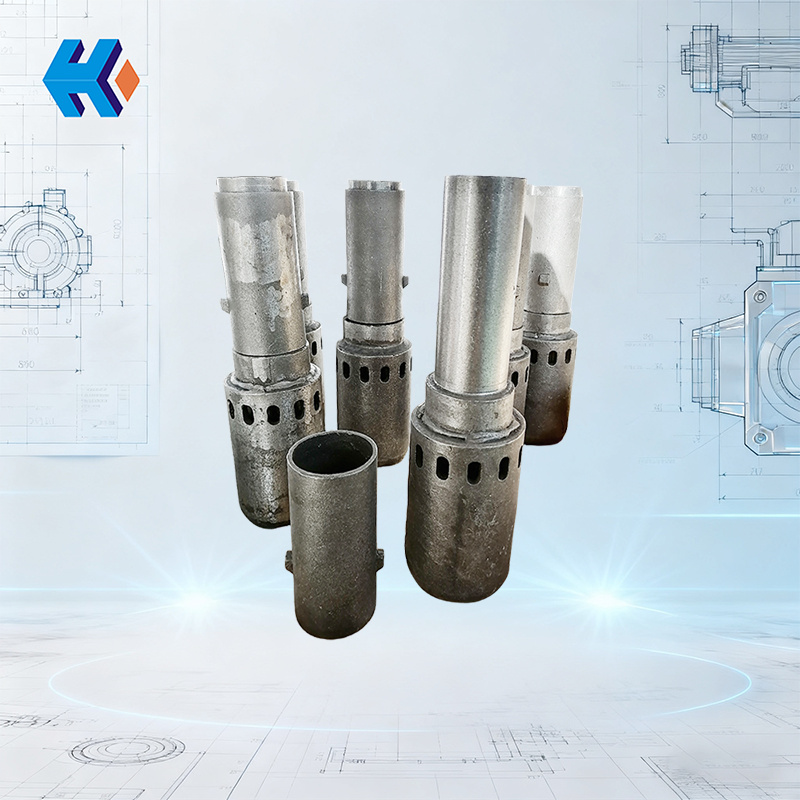

Air Cap Nozzle of Boiler Furnace

The air cap nozzle is a key air distribution device in boilers, installed on the air distribution plate at the bottom of the furnace. It directly affects combustion efficiency, fluidization quality, and operational stability, playing a decisive role in the safe operation of the boiler. It features a double-layer design, where air enters the interlayer from the bottom and is evenly discharged through small holes at the top. It has advantages such as uniform air distribution, anti-clogging, wear resistance, and long service life.

Core Functions of Air Cap Nozzle

-

Uniform air distribution: It disperses high-pressure primary air into fine streams to ensure full fluidization of bed materials (coal, limestone, ash, etc.).

- Maintains combustion efficiency: The stable fluidization state allows for thorough mixing of fuel and air, improving the burnout rate.

- Prevents slag leakage: A special structural design prevents bed material from flowing back into the air chamber, protecting the air duct system.

- Reduces wear: Optimizing airflow distribution reduces erosion and wear on the boiler water-cooled walls and the wind caps themselves.

Common Failures and Maintenance Methods

-

Common failures:

- Wear: During long-term operation, air cap nozzles are subjected to erosion from high-speed airflow and materials, causing wear on the head, edges, and other parts, which shortens their service life and affects air distribution.

- Clogging: Large pieces of debris or gangue in the coal may get stuck in the small holes of the air caps, or ash accumulation may also clog the holes. This impedes airflow, leading to insufficient fluidization and localized oxygen-deficient combustion, which reduces boiler efficiency.

- Burnout: When there is insufficient ventilation or the boiler operates at an excessively high temperature for a long time, the air cap nozzle may overheat and suffer burnout, leading to cracks, deformation, or even perforation.

- Maintenance methods:

- Regular inspection and replacement: Every 2000-3000 hours of operation or during each major overhaul, check the air caps for cracks, burnout, wear, or perforation at the top. Clean any clogs in the air holes, check for damaged threads, and promptly replace air caps with macroscopic defects or those that cannot be repaired.

- Optimize materials and structure: Use wear-resistant, high-temperature alloy or ceramic-coated air cap nozzles, increase the wall thickness, and adopt a single row of larger-diameter holes with an anti-wear cover to extend the service life and reduce the risk of wear and clogging.

- Adjust operating parameters: Avoid large-volume airflow. Adjust bed material height by discharging slag to stabilize bed pressure, ensure proper pressure drop across the air distribution plate, and achieve uniform air distribution to prevent localized poor fluidization and reduce material erosion on the wind caps.

- Cleaning and unclogging: Regularly enter the air chamber to clean out ash and coke blocks to prevent clogging. Use compressed air or special tools to clear clogged air cap nozzle holes.