Maintenance and Replacement Techniques for Induced Draft Fan Servo Valve Gasket TY9112C

Continuous vibration and alternating stress during the operation of induced draft fans (ID fans) can easily lead to aging and sealing failure of the servo valve's spectacle gasket, consequently affecting the servo valve's control accuracy. Today, we share maintenance and replacement techniques for the ID fan servo valve spectacle gasket TY9112C to help ensure the reliable operation of the servo valve.

The ID fan servo valve spectacle gasket TY9112C is a critical component for sealing and cushioning the servo valve. Prolonged exposure to vibration and alternating stress can cause issues like elastic degradation, cracking, and sealing surface wear. Failure to address these promptly may lead to hydraulic oil leakage, pressure fluctuations, and even cause the servo valve to jam. The TY9112C spectacle gasket, specifically provided for the harsh operating conditions of ID fans, is made from high-quality, fatigue-resistant, and anti-vibration materials. It offers superior adaptability and longer service life, making it the ideal choice for ensuring the stable operation of the servo valve.

So, how should one scientifically maintain and replace the induced draft fan servo valve spectacle gasket TY9112C?

1. Material Selection is Fundamental

Our specially engineered TY9112C spectacle gasket for high-vibration conditions utilizes a composite structure of Fluorine Rubber (FKM) + Metal Skeleton . This design retains the elastic sealing performance while providing vibration-resistant support. Its temperature range is -20℃~+200℃, it is resistant to phosphate ester fire-resistant hydraulic fluid corrosion, and its compression set is less than 15%, significantly outperforming ordinary non-metallic gaskets.

2. Regular Inspection is Essential

It is recommended to replace the TY9112C spectacle gasket mandatorily in conjunction with the ID fan overhaul cycle (typically every 2–3 years), or whenever the servo valve is dismantled for inspection. Even if the external appearance shows no damage, it should be treated as a "life-cycle part" . This is because internal micro-cracks are difficult to detect with the naked eye but can lead to sudden failure during the next startup.

3. Installation Must Be Standardized

Under normal operating conditions, replacement is suggested every 6-12 months; if the ID fan experiences high vibration frequencies or large load fluctuations, this interval should be shortened to 3-6 months. The replacement process must follow a standardized procedure:

-

Shutdown and Depressurization: Stop the unit, relieve pressure, close the upstream and downstream valves of the servo valve, and release residual pressure in the pipeline.

-

Removal: Disassemble the servo valve end cap and remove the old spectacle gasket.

-

Cleaning: Use a clean, soft cloth to wipe the mounting surface, removing any residual contaminants.

-

Inspection and Placement: Check that the mounting surface has no scratches. Place the TY9112C spectacle gasket smoothly into the mounting groove, ensuring it is properly seated.

-

Tightening: Secure the end cap with the specified torque, avoiding over-tightening which could deform the gasket.

-

System Startup and Monitoring: Start the system after replacement and monitor for any leakage or pressure instability. Only proceed to normal operation after confirming no abnormalities.

| Product Name | Model/Specification | Key Application/Purpose |

| Spectacle Gasket | HU28452-ZZ1 | Auxiliary sealing and cushioning for the servo valve; adaptable to different servo valve models; enhances sealing reliability in vibrating environments. |

| Servo Valve Connecting Rod | HU26242-122 | Transmits servo valve actuation commands; connects the spool to the actuator; ensures precise displacement transfer and strong anti-vibration performance. |

| Sealing Ring Assembly | HU26250-221 | Seals parts such as the servo valve body and end cap; prevents hydraulic oil leakage; suitable for high-pressure conditions. |

| Cylinder Assembly | HU27054-221G | Power component for the servo valve actuator; provides stable driving force; vibration-resistant and low operating noise. |

| ID Fan Expansion Joint | HU25244-222G | Absorbs thermal expansion/contraction and vibrational displacement in ID fan piping; reduces pipeline stress effects on the servo valve. |

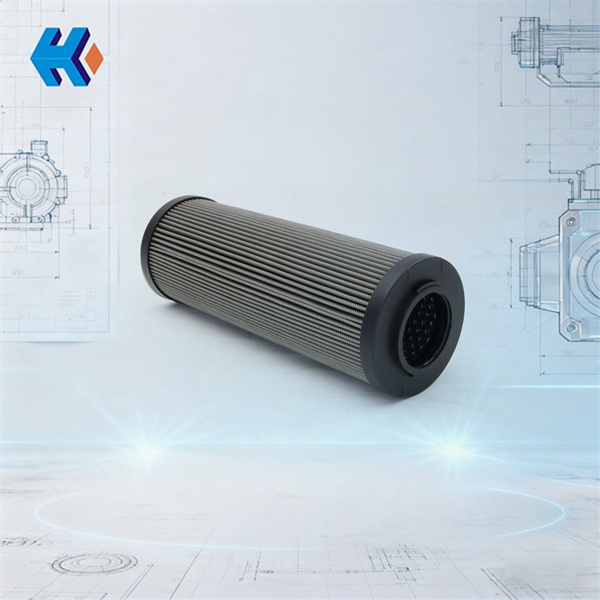

| ID Fan Oil Station Filter Screen | HU25240-221G | Filters impurities from the oil station hydraulic fluid; ensures the cleanliness of the oil entering the servo valve; prevents spool wear. |

| ID Fan Servo Valve | HU25244-221 | Core component for controlling ID fan flow and pressure; fast response and high control accuracy; suitable for harsh operating conditions. |

| ID Fan Blade Dust-proof Seal Assembly | HU27452-22 | Prevents dust from entering the connection points between the blades and the servo valve; protects moving parts and extends equipment service life. |

| Adjusting Rod Tightening Bolt & Nut | HU25040-222G | Secures the servo valve adjusting rod; high thread strength and anti-loosening performance; resists loosening risks caused by vibration. |

| O-Ring Seal | HU25648-222 | Auxiliary sealing for various sealing points; adaptable to multiple interface sizes; oil-resistant, wear-resistant, and provides stable sealing effect. |

HKZX-2025-12-12