Why Ultrasonic Testing is Mandatory for Repairing Turbine Thrust Bearings

During a steam turbine overhaul, if the turbine thrust bearing pad exhibits babbitt lining detachment, cracks, or wear, it often requires local repair or re-babbitting. After repair, non-destructive testing (NDT) must be performed on the bearing surface to ensure there are no hidden defects. However, a crucial point here is that repaired bearing pads have "no machining allowance"—meaning they are put directly back into service after repair, without any further turning or scraping.

This mandates that the testing method must be precise, non-destructive, and capable of detecting deep-seated defects.

【Core Problem】Why Can't Dye Penetrant Testing Be Used?

Many experienced technicians prefer the dye penetrant method (PT) for checking cracks due to its simplicity and visual clarity. However, for repaired bearing pads, penetrant testing has three major "fatal flaws":

1. Only Detects Surface Issues, Misses Deep-Seated Debonding

- The principle of dye penetrant testing is to allow a liquid penetrant to seep into surface-breaking discontinuities.

- It can only find cracks open to the surface, but is completely ineffective against internal defects like separation, debonding, or weak bonds between the babbitt metal and the steel backing.

- These internal defects are precisely the "number one killers" of bearing pad failure.

2. Penetrant Residue Can Destroy the Oil Film

- Bearing pads rely on a lubricating oil film for load support during operation.

- If penetrants are used, even if thoroughly cleaned, trace residues may mix with the lubricating oil, disrupting the oil film continuity, causing localized dry friction, and ironically leading to new wear.

3. Repaired Surface Does Not Allow Secondary Contamination

- The repaired bearing surface has high precision and no allowance for further machining. Any chemical attack or wiping from chemical reagents could compromise the surface quality.

- Penetrant testing requires cleaning and developing, an uncontrollable process that carries risk.

✅ Why is Ultrasonic Testing the Only Choice?

Ultrasonic Testing (UT) has become the "gold standard" for inspecting repaired bearing pads because it perfectly matches the unique requirements of these components:

Detects Internal Defects

- Ultrasonic waves can penetrate the babbitt layer and reach the steel-babbitt interface.

- Through the echo signals, internal defects such as debonding, porosity, and inclusions can be clearly identified, with an accuracy up to 0.1mm.

Non-Destructive and Non-Contaminating

- The testing process only uses a couplant (such as glycerin or a specialized couplant), which will not corrode or contaminate the bearing surface.

- It is easy to clean after testing and does not affect subsequent lubrication performance.

Suitable for "Zero-Allowance" Repairs

- Since no further machining occurs after the repair, the inspection must be accurate the first time.

- Ultrasonic testing provides quantifiable data on depth, position, and area, offering a reliable basis for determining fitness for service.

【Recommended Product】—Full-Process Control from Repair to Inspection

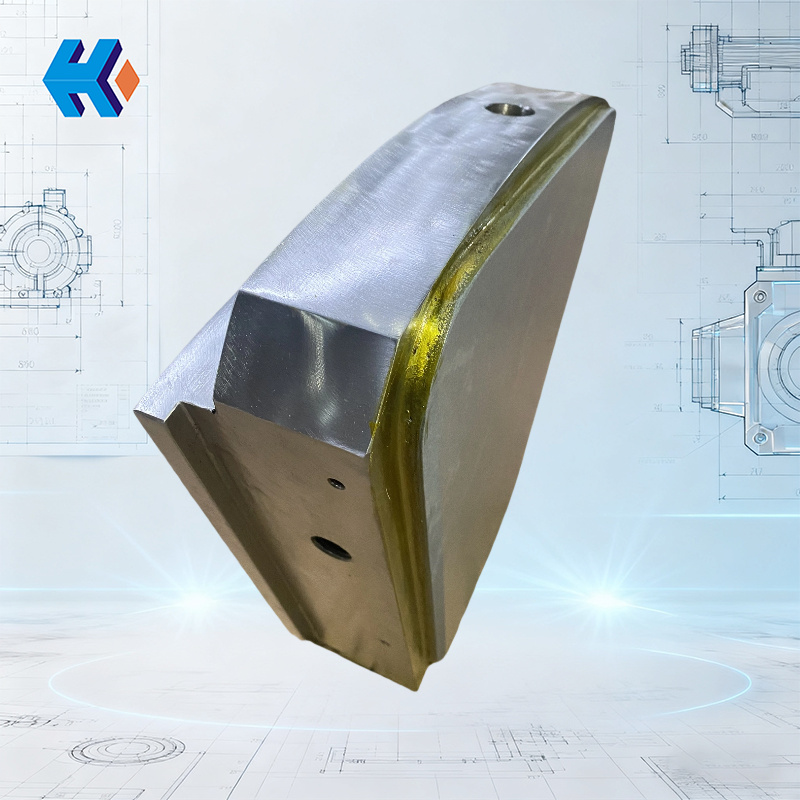

The steam turbine thrust bearing pads manufactured by our company not only utilize high-purity tin-based babbitt metal and optimized casting processes to ensure original bond strength, but, more importantly:

- Designed for Inspectability: The pad structure facilitates ultrasonic probe scanning; the interface between the steel backing and babbitt is flat, providing clear echo signals.

- Provides Integrated Repair and Inspection Solution: For old pads requiring on-site repair, we provide dedicated ultrasonic testing procedures and probe selection recommendations to ensure accurate and reliable inspection results.

Multiple power plants collaborating with us have reported: high pass rates after ultrasonic inspection of repaired pads, stable bearing temperatures during operation, and no debonding incidents.

Remember this: A bearing pad is a "bearing," not just a "part." Its failure is often sudden. Once debonding occurs, the mild result is a sharp rise in bearing temperature, and the severe result is shaft journal scoring and unit shutdown.

Therefore, when it comes to repairing bearing pads, the choice of inspection method is the choice of safety standard. Dye penetrant testing may seem convenient, but it conceals hidden dangers; ultrasonic testing may seem troublesome, but it is the true "farsighted eye" that ensures safety.

-

Stop Booster Pump Leaks: Master the HZB253-640-01-05 Oil Flinger Install

Stop lube oil leaks. Learn how to control the HZB253-640-01-05 oil flinger gap, why install direction matters, and how to match its life to your bearing overhaul.02-25

-

Why Re-using the HZB253-640-01-03 Locking Washer Risks Total Booster Pump Failure

Don't let bolts come loose. Learn how to check the HZB253-640-01-03 locking washer for fatigue, why you shouldn't re-use it, and how to install it right.02-04

-

Stop Pump Leaks: A Maintenance Guide for the HZB253-640-01-13 Shaft Sleeve

Prevent booster pump shutdowns. Learn how to spot HZB253-640-01-13 shaft sleeve erosion, pitting, and vibration issues before they ruin your mechanical seals.02-02

-

Stability Principles of the HD452D11 Sliding Bearing Under Extreme Dynamic Loads

Master the HD452D11 sliding bearing. Learn how its oil film and anti-vibration design protect feed pump shafts from wear under high-speed power plant loads.01-31

-

FA1D56A-00-1/4 Gasket: Fitting and Shock Protection for Pump Seal Chambers

Stop leaks in your feed pump seal water chamber. Learn how the FA1D56A-00-1/4 gasket matches your pump to resist pressure jumps and cavitation shocks.01-31