Stop Pump Leaks: A Maintenance Guide for the HZB253-640-01-13 Shaft Sleeve

The HZB253-640-01-13 shaft sleeve is a core part that protects the booster pump shaft. It sits on the outside of the shaft to help the seals work and stop the main shaft from wearing down. Since booster pumps run at high speeds for a long time, these sleeves often fail. Many crews ignore the sleeve, but if it breaks, it can take down the whole pump or even the entire feed water system. You need to know how the HZB253-640-01-13 shaft sleeve fails and how to watch for it to keep your plant running.

1. Sleeve Failure: A Chain Reaction of Problems

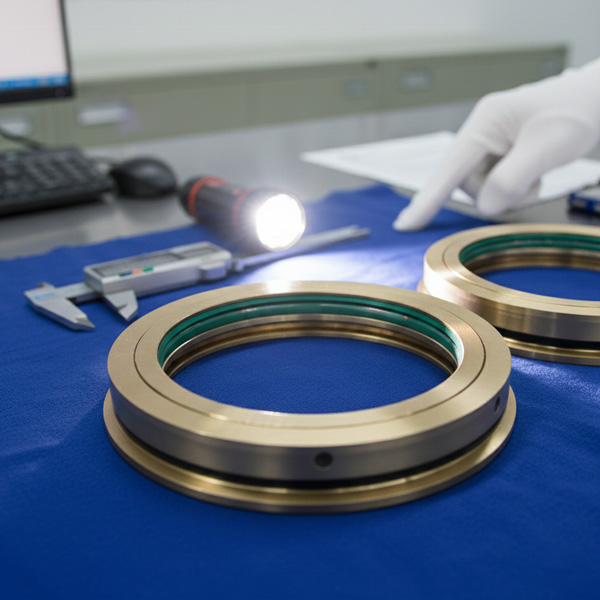

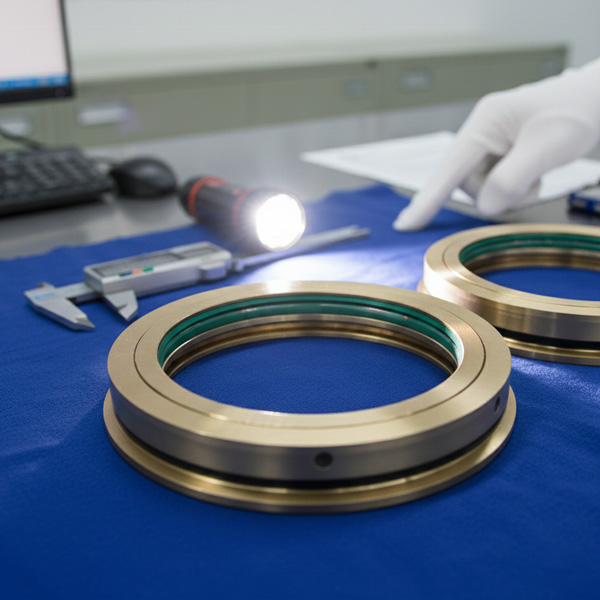

If the HZB253-640-01-13 shaft sleeve fails, the first thing to go is the mechanical seal. The seal sits on the sleeve, so if the sleeve surface is worn or bent, the seal won't fit tight and water will leak out everywhere.

A leak is more than just a mess; it rusts the parts around the pump and ruins the lubrication. This makes the shaft wear out even faster. If you don't fix a bad HZB253-640-01-13 shaft sleeve, the pump will start shaking and making a lot of noise. Eventually, you might break the main shaft or the impeller, forcing you to shut down the unit and lose money. We have seen many cases where a small sleeve problem turned into a massive pump rebuild because it was ignored.

2. Common Failures: Watch Out for Surface Pitting

The HZB253-640-01-13 shaft sleeve doesn't just fail in one way. The most common problem we see is local erosion pitting.

The water in the booster pump usually has tiny bits of dirt in it. When the pump spins fast, this dirty water hits the sleeve surface like a sandblaster. This eats away at the metal, especially where the mechanical seal touches the sleeve. Eventually, you get uneven wear or deep pits. This happens a lot in boiler booster pumps because the water isn't always perfectly clean. You might also see even wear where the whole sleeve gets thin, or cracks caused by the pump starting and stopping too much, which shocks the metal with heat.

3. More Than Just a Leak: The Hidden Damage

A bad sleeve does more than just ruin the seal. When the HZB253-640-01-13 shaft sleeve wears out, the gap between it and the shaft gets too big. This makes the pump shaft bounce around while it spins.

This extra vibration eats the impellers and bearings fast. Even worse, it can scratch or bend the main pump shaft. The shaft is expensive and hard to fix, so keeping the HZB253-640-01-13 shaft sleeve in good shape is the best way to save the whole pump. The sleeve needs other parts to work right, too. Here is a list of parts that help the HZB253-640-01-13 shaft sleeve stay stable:

| Part Name | Model / Specification |

|---|---|

| Thrust Ring | FK5F32(I)M-00(1/2) |

| Thrust Pad | A1GB-10700-00 |

| Impeller Mouth Ring | HZB253-640-03-04-00 |

| Elastic Retaining Ring | HPT300-340-03-03 |

| Locking Gasket | FA1B56-A3-103403 |

| Core Bundle O-Ring | DG600-240M |

| Thin-Wall Radial Bearing | FAIB56-A2-104287 |

| Seal Retaining Ring | FK5D32 |

| Spring Plate | HTHP-01-02-19-07 |

| O-Ring Rubber Seal | DG600-240(V)M |

If the O-rings or seal rings are bad, more dirty water hits the sleeve. If the bearings are shaky, the HZB253-640-01-13 shaft sleeve takes more load. We sell the whole original set so everything matches up.

4. Field Monitoring: How to Tell if the Sleeve is Dying

Since the sleeve is inside the pump, you can't see it while it's running. You have to use clues to check it.

First, watch the vibration. If the HZB253-640-01-13 shaft sleeve is worn or loose, the pump will shake more than usual, especially sideways (radial vibration). If you hear weird noises, that's another sign. You can also check the oil. When a sleeve wears down, it drops tiny metal flakes into the lube oil. If your oil test shows a lot of iron suddenly, your sleeve might be grinding away. Finally, if the mechanical seal starts leaking even a little, check the sleeve. Usually, the sleeve surface is the real reason the seal failed.

5. Maintenance Tips: Stopping Failure Before it Starts

Check the seal and vibration during your daily rounds. If something looks or feels wrong, don't wait. When you have the pump open for a check-up, look at the HZB253-640-01-13 shaft sleeve for any pits, scratches, or cracks. If it's not smooth, replace it.

Always use an original HZB253-640-01-13 shaft sleeve. Off-brand sleeves use cheap metal that wears out way faster under dirty water. Also, keep your water clean! Filtering the water means less sand hitting the sleeve. Good lubrication also helps stop the friction that thins the metal.

Conclusion: Small Part, Big Importance

The HZB253-640-01-13 shaft sleeve is a small part, but if it fails, the damage is huge. Surface pitting will ruin your seals, shake your pump, and eventually break your shaft. Use vibration and oil tests to catch problems early so you don't have to deal with a broken pump.

Need an original HZB253-640-01-13 shaft sleeve, booster pump parts, or technical advice? Contact us. We have the high-quality sleeves and the field support to keep your pumps running smooth and your costs low.

HKCYT-2026-02-02

-

Stop Pump Leaks: A Maintenance Guide for the HZB253-640-01-13 Shaft Sleeve

Prevent booster pump shutdowns. Learn how to spot HZB253-640-01-13 shaft sleeve erosion, pitting, and vibration issues before they ruin your mechanical seals.02-02

-

Stability Principles of the HD452D11 Sliding Bearing Under Extreme Dynamic Loads

Master the HD452D11 sliding bearing. Learn how its oil film and anti-vibration design protect feed pump shafts from wear under high-speed power plant loads.01-31

-

FA1D56A-00-1/4 Gasket: Fitting and Shock Protection for Pump Seal Chambers

Stop leaks in your feed pump seal water chamber. Learn how the FA1D56A-00-1/4 gasket matches your pump to resist pressure jumps and cavitation shocks.01-31

-

HPT200-300-05-01A-00 Oil Seal Assembly: Tips for Stopping Leaks After a Swap

Stop pump leaks for good. Learn how to install the HPT200-300-05-01A-00 oil seal assembly correctly, avoid common mistakes, and check for a perfect seal.01-28

-

ID56-H75/95-00 Mechanical Seal: Spotting Leaks and Planning Repairs for Booster Pumps

Stop booster pump leaks. Learn how to spot early warning signs like heat and noise for the ID56-H75/95-00 mechanical seal to plan your repairs before a failure.01-23