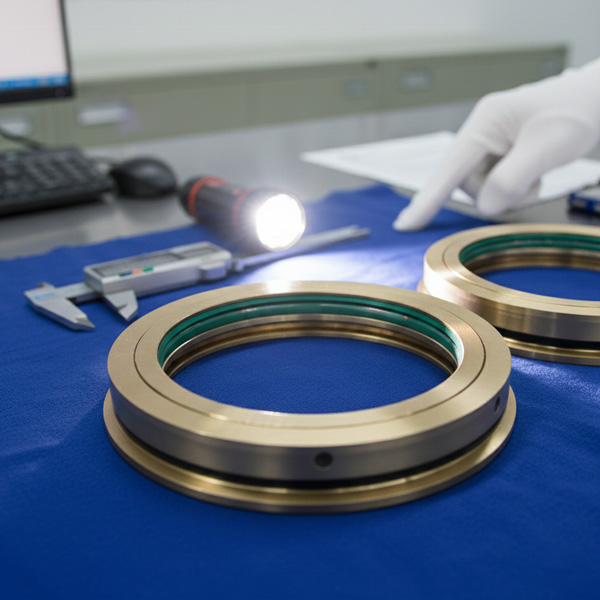

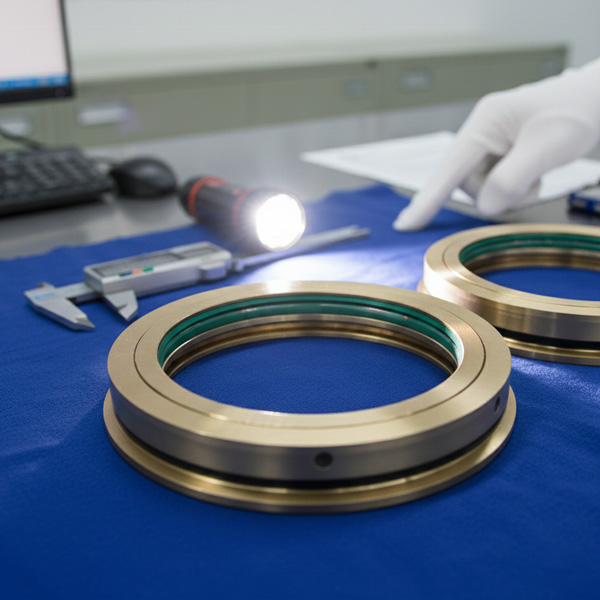

ID56-H75/95-00 Mechanical Seal: Spotting Leaks and Planning Repairs for Booster Pumps

The ID56-H75/95-00 mechanical seal is the most important part for keeping your boiler booster pump from leaking. These pumps move hot stuff all day long, so the seal has to handle a lot of heat and shaking. If the seal fails, you get leaks. This might just make the pump less efficient, or it could cause a total shutdown. If you know how it fails and catch the early warning signs, you can plan your maintenance before things get bad. This stops big surprises.

1. How the Seal Fails: Slow Leaks vs. Sudden Breaks

Most of the time, the ID56-H75/95-00 mechanical seal fails slowly. The faces wear down, the O-rings get old, or the springs stop pushing hard enough. This makes the leak get bigger and bigger over time.

At first, you might just see a little wet spot on the seal cover. Later, it starts to drip, and finally, it's a steady leak. Since this happens slowly, it gives you time to plan a fix. Our original ID56-H75/95-00 mechanical seal uses materials made for high heat, so it stays in that "slow leak" phase longer than cheap parts. Sudden breaks don't happen often. They usually happen if big dirt bits scratch the face or if the pump starts too fast.

2. Warning Signs: What to Look For During Rounds

The easiest sign is a leak. When you walk by the pump, check the seal cover. If it looks wet or has oily gunk on it, the ID56-H75/95-00 mechanical seal is starting to wear out. Even if it isn't dripping yet, the damage has started.

Heat is another clue. Use a temp gun on the seal cover. If it is way hotter than normal and nothing else is near it, the seal faces are probably rubbing too hard. Also, listen for weird sounds. If you hear a "chirp" or an uneven hum at the seal end, something is loose or a spring is dead. Also, check your oil. If the booster pump oil looks like milk or changes color, the mechanical seal is leaking on the inside.

3. Monitoring: Getting Ready for a Planned Fix

You need a simple checklist for the booster pump seal. Write down the leaks, the heat, and any noises every shift. If you look at this data over a few weeks, you can guess when the ID56-H75/95-00 mechanical seal will finally need to be replaced.

Oil testing is a big help, too. If you find the pump liquid in the lube oil, you can tell how bad the internal leak is. During short stops, take the seal cover off. Look for scratches on the faces or cracks in the O-rings. Fixing a small thing now is better than a big disaster later.

The ID56-H75/95-00 mechanical seal works best when the other parts in the pump are good. Here is a list of parts for this pump. Using original ones keeps the load off your seal:

| Part Name | Model / Specification |

|---|---|

| Stage Guide Vane | GNPD-FK6B37M-04-03 |

| Radial Bearing | FK4E39K-05-09 |

| Seal Ring | DG600-240-07-03 |

| Large Nut M48 | DG750-180-01-07 |

| Seal Ring | HTHP-01-02-17-04 |

| Mechanical Seal Cover | FA1D56-03-01 |

| Feed Pump Coupling Diaphragm | HGD8-4700-00721 |

| Seal Ring (Shaft) | FAID56-03-05A |

| Thrust Pad | FK5D32M-06-02-00 |

| Pump Impeller | YOT46-508-05-04 |

| Mechanical Seal (Assembly) | HZB253-640A |

If parts like the bearings or the coupling are worn out, they cause a lot of vibration. This shaking hits the ID56-H75/95-00 mechanical seal and makes it fail much faster.

4. Maintenance Tips: Protecting the Seal

When you put in a new ID56-H75/95-00 mechanical seal, everything has to be clean. Even a tiny scratch on the face during the install will cause a leak. Make sure the O-rings sit right and follow the bolt torque rules in the book.

Try not to start and stop the pump too much. This causes "thermal shock" which ruins the seal. Also, make sure the water stays clean. Dirt in the water is like sandpaper to the seal faces. Every time you open the seal for a check-up, you should put in new O-rings and springs. It's always better to use original parts made for this seal.

Conclusion: Early Warnings Keep the Pump Steady

The ID56-H75/95-00 mechanical seal usually fails slowly, not all at once. If you watch for leaks, heat, and noise, you can catch it early. Planning your repairs instead of waiting for a break saves the plant money and stops the pump from quitting when you need it most.

Looking for an original ID56-H75/95-00 mechanical seal, backup parts, or help with an inspection? Send a message now. We have the high-quality seals and the tech tips to keep your booster pumps running without leaks.

HKCYT-2026-01-23

-

Why Re-using the HZB253-640-01-03 Locking Washer Risks Total Booster Pump Failure

Don't let bolts come loose. Learn how to check the HZB253-640-01-03 locking washer for fatigue, why you shouldn't re-use it, and how to install it right.02-04

-

Stop Pump Leaks: A Maintenance Guide for the HZB253-640-01-13 Shaft Sleeve

Prevent booster pump shutdowns. Learn how to spot HZB253-640-01-13 shaft sleeve erosion, pitting, and vibration issues before they ruin your mechanical seals.02-02

-

Stability Principles of the HD452D11 Sliding Bearing Under Extreme Dynamic Loads

Master the HD452D11 sliding bearing. Learn how its oil film and anti-vibration design protect feed pump shafts from wear under high-speed power plant loads.01-31

-

FA1D56A-00-1/4 Gasket: Fitting and Shock Protection for Pump Seal Chambers

Stop leaks in your feed pump seal water chamber. Learn how the FA1D56A-00-1/4 gasket matches your pump to resist pressure jumps and cavitation shocks.01-31

-

HPT200-300-05-01A-00 Oil Seal Assembly: Tips for Stopping Leaks After a Swap

Stop pump leaks for good. Learn how to install the HPT200-300-05-01A-00 oil seal assembly correctly, avoid common mistakes, and check for a perfect seal.01-28