Why Re-using the HZB253-640-01-03 Locking Washer Risks Total Booster Pump Failure

The HZB253-640-01-03 locking washer is a small but vital part used to hold the booster pump shaft system together. It sits between the bolt and the connected part to stop things from coming loose under high speed and heavy vibration. During a check-up, you must decide if the washer is tired (fatigued) and needs to be tossed. If you install it wrong or try to re-use an old one, the bolts will back out, which can wreck the impellers and sleeves. Knowing how to judge the HZB253-640-01-03 locking washer is a huge part of pump maintenance.

1. Maintenance Check: How to Tell if the Washer is Dead

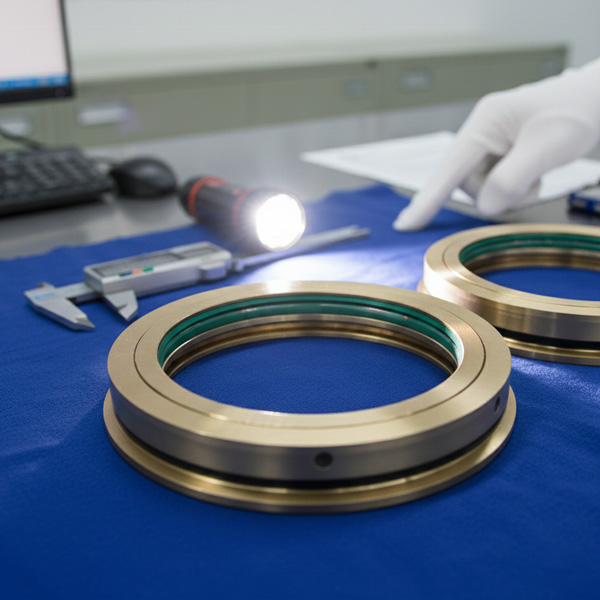

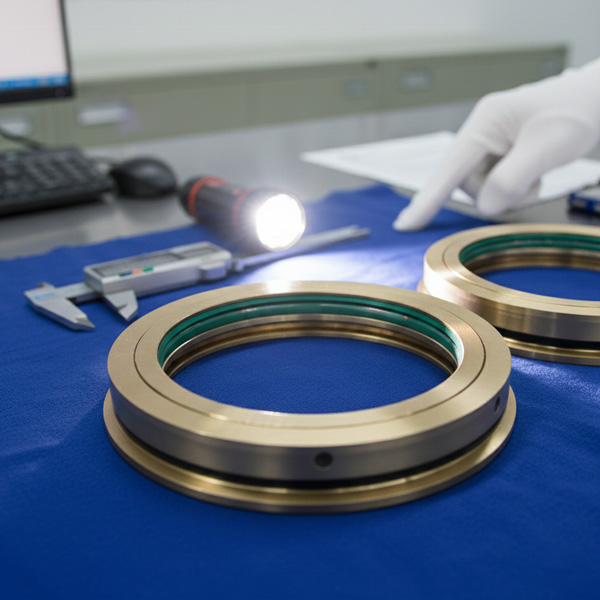

You can tell if a HZB253-640-01-03 locking washer is worn out just by looking at it. You don't need fancy tools—just follow these clues.

First, look for cracks. When the washer gets tired from vibration, the metal loses its toughness and tiny lines appear on the edges or the teeth. If these lines get wide, the washer will snap and the bolt will get loose. Next, check the shape. A good washer is flat and springy. If it looks warped or stays bent when you press it, the material is dead and won't hold the bolt anymore. Finally, check the teeth. The teeth do the actual locking work. If the teeth are worn down, chipped, or blunt, the HZB253-640-01-03 locking washer belongs in the trash.

2. Re-use Rules: Can You Use an Old Washer Twice?

Many guys think if a washer looks okay, they can use it again. This is a big mistake. The HZB253-640-01-03 locking washer is a one-time use part. Even if it looks fine, the metal has already been stretched and stressed.

Once a washer has been tightened and shaken by the pump, it loses its memory and its grip. If you put it back in, it will likely crack or fail to stop the bolt from spinning. This leads to loose parts, vibrating shafts, and eventually, a pump shutdown. In power plants, you should never re-use them. Always put in a new, original HZB253-640-01-03 locking washer to be safe. Our original washers are made to handle these exact high-vibration jobs.

3. Part Matching: What Works with the Washer

The HZB253-640-01-03 locking washer needs the bolts and rings around it to be in good shape, too. If the bolts are bad, the washer can't do its job. Here is a list of parts that work with this washer on the booster pump:

| Part Name | Model / Specification |

|---|---|

| Retaining Ring | DG600-240-07-02(4) |

| Bolt | HPT200-330-01BR-02 |

| Last Stage Guide Vane | HPT200-330-04-11 |

| Stud Bolt | FA1D53-m24x225 |

| Shaft Sleeve | FA1D56-01-07-17 |

| First Stage Impeller | DG600-240(S)-03-09 |

| Throttling Plug | HTHP-01-02-19-14 |

| Locking Gasket | HZB253-640-01-14 |

| First Stage Impeller (Alt) | FT13RA33M-03-02 |

| Impeller | FA1D56B-03 |

The quality of the bolts and rings keeps the HZB253-640-01-03 locking washer from getting crushed too soon. We provide the full set of original parts so everything fits perfectly during your repair.

4. Install Rules: Avoiding Costly Mistakes

How you put the new washer in matters just as much as the part itself. If you mess up the install, even a new HZB253-640-01-03 locking washer will fail fast.

Clean the surfaces first. Wipe down the bolt and the pump parts to get rid of oil and metal chips. If there's junk in the way, the washer won't sit flat. Then, line it up right. Make sure the washer is centered on the bolt and the teeth are sitting in the right slots. If it's crooked, it won't lock. Use a torque wrench to tighten the bolt. Don't just guess. If you go too tight, you'll crack the teeth; too loose, and it won't work. One more thing: don't force it. If it doesn't want to go in, check the size. Forcing a HZB253-640-01-03 locking washer just creates cracks before the pump even starts.

5. Maintenance Advice: Keeping Things Tight

Keep a log of when you replace these washers. It helps you see how long they are lasting under your specific plant conditions. Always pick the original HZB253-640-01-03 locking washer. Off-brand ones are usually the wrong size or made of cheap metal that fails under vibration.

When you swap the washer, take a look at the bolt and the retaining rings, too. If they look worn or rusty, replace them with original parts at the same time. This stops the HZB253-640-01-03 locking washer from failing early because of a bad bolt.

Conclusion: Do the Job Right to Stay Running

The HZB253-640-01-03 locking washer is a small part, but if a bolt comes loose, the whole pump is in trouble. Check for cracks and wear, never re-use old ones, and follow the torque rules. This is how you keep your booster pump and feed system stable for the long haul.

Need an original HZB253-640-01-13 locking washer, bolts, or installation help? Contact Dongfang SRI. We have the parts and the tech support to help you get your pump maintenance done right.

HKCYT-2026-2-4

-

Why Re-using the HZB253-640-01-03 Locking Washer Risks Total Booster Pump Failure

Don't let bolts come loose. Learn how to check the HZB253-640-01-03 locking washer for fatigue, why you shouldn't re-use it, and how to install it right.02-04

-

Stop Pump Leaks: A Maintenance Guide for the HZB253-640-01-13 Shaft Sleeve

Prevent booster pump shutdowns. Learn how to spot HZB253-640-01-13 shaft sleeve erosion, pitting, and vibration issues before they ruin your mechanical seals.02-02

-

Stability Principles of the HD452D11 Sliding Bearing Under Extreme Dynamic Loads

Master the HD452D11 sliding bearing. Learn how its oil film and anti-vibration design protect feed pump shafts from wear under high-speed power plant loads.01-31

-

FA1D56A-00-1/4 Gasket: Fitting and Shock Protection for Pump Seal Chambers

Stop leaks in your feed pump seal water chamber. Learn how the FA1D56A-00-1/4 gasket matches your pump to resist pressure jumps and cavitation shocks.01-31

-

HPT200-300-05-01A-00 Oil Seal Assembly: Tips for Stopping Leaks After a Swap

Stop pump leaks for good. Learn how to install the HPT200-300-05-01A-00 oil seal assembly correctly, avoid common mistakes, and check for a perfect seal.01-28