Analysis of Failure Modes and Monitoring Techniques for FA1D56-01-03A Pump Shafts

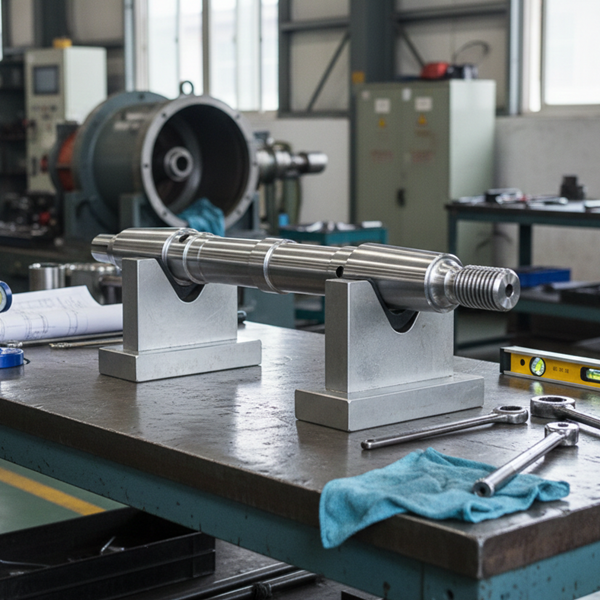

The FA1D56-01-03A pump shaft is the main power transmitter for feed pumps in thermal power plants. It spins at high speeds to drive impellers while dealing with constant alternating stress. Thermal shocks are also a daily reality—quick temperature swings during startups and stops cause internal stress points. All these factors make the pump shaft a high-risk part for failure. Learning how it fails and how to spot damage without taking the pump apart is the only way to avoid a disaster. If a pump shaft snaps unexpectedly, it usually means a forced shutdown and a massive financial loss.

1. Main Failure Modes: Why Damage Happens

Fatigue cracking is the #1 killer of the FA1D56-01-03A pump shaft. Constant stress cycles start tiny cracks at surface flaws. Over time, these cracks grow until the shaft eventually snaps.

Stress tends to pile up at sharp spots like shaft shoulders and keyways. High-speed operation makes even a tiny scratch turn into a deep crack very quickly. Our original FA1D56-01-03A pump shaft is specially reinforced at these high-stress zones to lower the risk.

Thermal cracking is another big threat. Fast heating or cooling creates thermal stress that adds to the mechanical load. If it goes past the material's limit, micro-cracks appear on the surface and dig inward. You also have to watch for wear—friction at the journals or corrosion from the water can ruin the shaft's dimensions and fit.

2. Non-Dismantling Monitoring: Early Warning Signs

Vibration monitoring is the best way to check the FA1D56-01-03A pump shaft while it's still running. When a crack starts forming, the vibration signal changes. You need to watch the amplitude and frequency patterns closely.

If you see a sudden jump in a specific frequency along with a rhythmic throb, a crack might be growing. Spectrum analysis can help pin down where the damage is. We offer calibration services for monitoring the FA1D56-01-03A pump shaft to make these predictions more accurate.

Ultrasonic testing (UT) is another great tool. It sees through the metal to find internal cracks. You just press the probe against the shaft surface during a short outage. There’s no need to pull the whole rotor out.

3. Support Monitoring: Catching Abnormal Parameters

Temperature checks help confirm the shaft's health. If the journal area gets too hot, it could be a sign of heavy wear or a crack causing extra friction. Combined with vibration data, this makes your diagnosis much stronger.

Oil analysis also helps. As the FA1D56-01-03A pump shaft wears or cracks, tiny metal flakes fall into the lube oil. If your lab report shows a sudden spike in iron (Fe) levels, you likely have fatigue damage starting. Even your ears can help—a cracked shaft often makes an irregular clicking or humming noise.

4. Best Practices: Reducing the Risk of Failure

To keep the FA1D56-01-03A pump shaft alive longer, you have to control how the pump runs. Avoid too many starts and stops to limit thermal shock. When you do start up, follow the temperature ramp-up rules strictly. Keep your bearings and seals in top shape. If a bearing sticks, it puts uneven force on the shaft, creating a localized stress point.

The stability of the FA1D56-01-03A pump shaft also depends on the parts around it. Below is a list of core parts that must fit perfectly to keep the shaft safe:

| Part Name | Model / Specification |

|---|---|

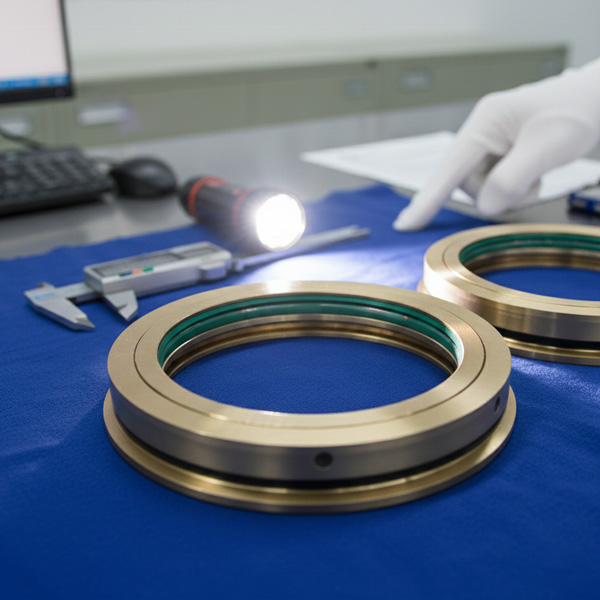

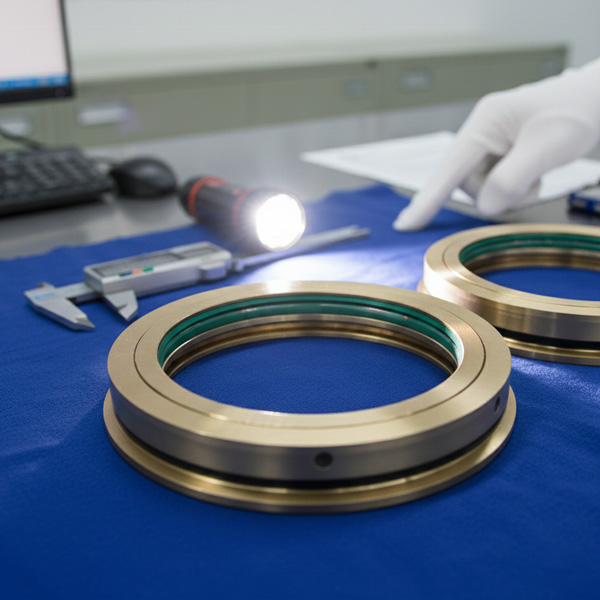

| Mechanical Seal | HZB253-H75/110-G115-E1 |

| Spring Plate | HTHP-01-02-19-08 |

| Gasket | ZB253-640-03-06 |

| Booster Pump Mech Seal | FAID56 |

| Guide Vane | DG600-240-04-13 |

| Shaft Sleeve | FAID56-01-05 |

| 1st Stage Impeller | FT9Q36M-03-02 |

| Seal Retaining Ring | DG600-240-07-02 |

| Thrust Bearing Assembly | HZB253-640A-02-05-00 |

| Gasket | FA1D56-02-04 |

| Guide Vane (Mid-Stage) | 0FK5F32KM-04-04 |

5. Dealing with Damage: Act Fast

If you find a crack in the FA1D56-01-03A pump shaft, you have to deal with it immediately. Very light surface cracks can sometimes be ground out and repaired, but you must do stress-relief treatment afterward.

If the crack is deep or in a critical spot, don't risk a repair—just replace the shaft. Using a patched-up shaft is a ticking time bomb. When you replace it, always use an original FA1D56-01-03A pump shaft to ensure the metal and precision are correct.

Conclusion: Monitoring Keeps the Unit Running

Failures in the FA1D56-01-03A pump shaft usually come from a mix of fatigue and heat. By using vibration and ultrasonic tools, you can catch the early signals and avoid a catastrophic break.

Need an original FA1D56-01-03A pump shaft, technical monitoring, or on-site testing? Contact us. We provide the high-quality shafts and the expert support to keep your feed pump running safely.

HKCYT-2026-01-21

-

Why Re-using the HZB253-640-01-03 Locking Washer Risks Total Booster Pump Failure

Don't let bolts come loose. Learn how to check the HZB253-640-01-03 locking washer for fatigue, why you shouldn't re-use it, and how to install it right.02-04

-

Stop Pump Leaks: A Maintenance Guide for the HZB253-640-01-13 Shaft Sleeve

Prevent booster pump shutdowns. Learn how to spot HZB253-640-01-13 shaft sleeve erosion, pitting, and vibration issues before they ruin your mechanical seals.02-02

-

Stability Principles of the HD452D11 Sliding Bearing Under Extreme Dynamic Loads

Master the HD452D11 sliding bearing. Learn how its oil film and anti-vibration design protect feed pump shafts from wear under high-speed power plant loads.01-31

-

FA1D56A-00-1/4 Gasket: Fitting and Shock Protection for Pump Seal Chambers

Stop leaks in your feed pump seal water chamber. Learn how the FA1D56A-00-1/4 gasket matches your pump to resist pressure jumps and cavitation shocks.01-31

-

HPT200-300-05-01A-00 Oil Seal Assembly: Tips for Stopping Leaks After a Swap

Stop pump leaks for good. Learn how to install the HPT200-300-05-01A-00 oil seal assembly correctly, avoid common mistakes, and check for a perfect seal.01-28