The Buyer's Guide to FA1B56-A2-104287 Radial Bearing: Fit, Material, and Life

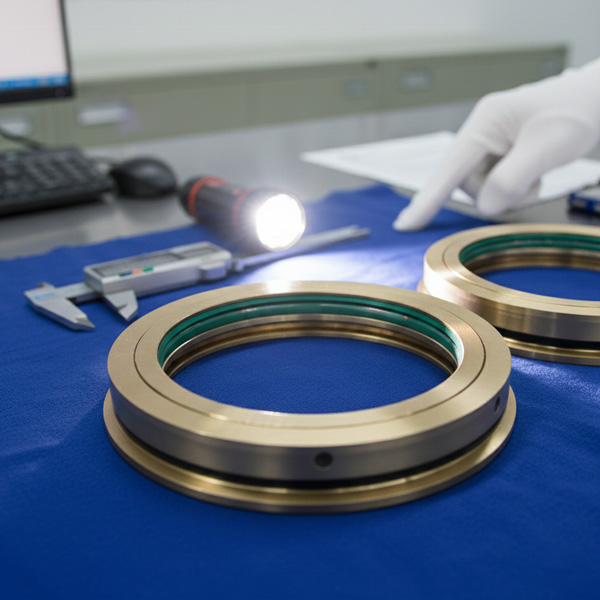

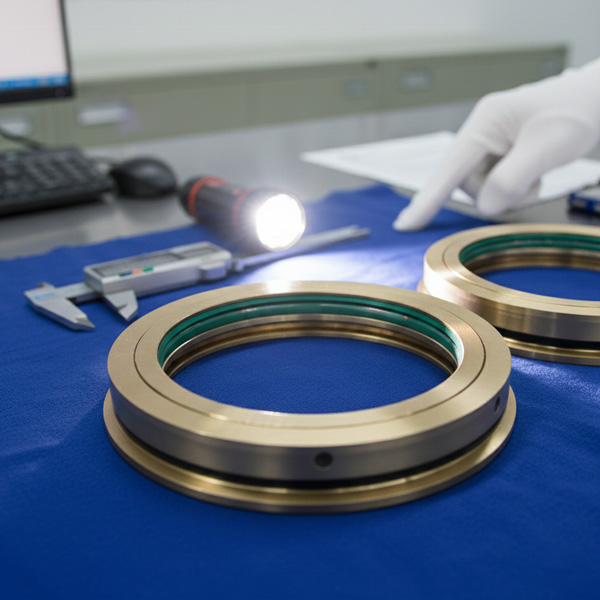

The FA1B56-A2-104287 radial bearing is a thin-walled component that sits at the heart of your feedwater pump. Getting the radial clearance right is a big deal. It directly controls the temperature, vibration, and how long the bearing lasts. Because feed pumps work under heavy loads and high speeds, a clearance that is too big or too small will cause a breakdown. Being precise with your measurements and adjustments is the only way to keep the unit stable. In the field, we usually use the Shaft Lift Method for these thin-walled bearings instead of the old Lead Wire Method. There's a good reason for that.

1. Choosing the Method: Why the Shaft Lift Method Fits Thin-Walled Bearings

The Lead Wire Method is fine for thick bearings, but it's a bad idea for the FA1B56-A2-104287 radial bearing. Thin-walled shells deform easily. If you crush a lead wire inside, you might actually change the shape of the shell, giving you a fake reading.

The Shaft Lift Method is much safer for thin structures. You use a dial indicator to watch how much the journal rises, which tells you the clearance. You don't have to take the bearing apart, so there's less risk of scratching the shells. Just make sure the journal and bearing surfaces are clean—oil or grit will mess up your numbers.

To do it right, fix the dial indicator to the bearing housing. Put the tip vertically on the top of the shaft. Slowly lift the shaft and write down the movement. Do it a few times and take the average to cut down on errors.

2. Checking the Standards: Comparing Data to Design

Once you have your numbers, you need to check them against the design range for the FA1B56-A2-104287 radial bearing. Every pump is a bit different based on its speed and load, so there isn't one magic number for everyone.

- Clearance too big: If the gap is too wide, the oil film can't support the shaft. You'll get nasty vibrations and loud noises. It also lets too much oil leak out, leaving the bearing dry. Eventually, the shaft will start hammering the shell, which kills the bearing life.

- Clearance too small: This is even more dangerous. If the gap is too tight, the oil film is too thin. Friction goes way up, and the temperature spikes. This burns the oil and can cause the Babbitt metal to melt or seize. If it gets bad enough, the pump will lock up and trip the unit.

If you need the original design specs or calibration help, just ask us.

3. Adjustment Tips: Fixing the Gap

If your clearance is out of spec, you need to fix it without hurting the bearing.

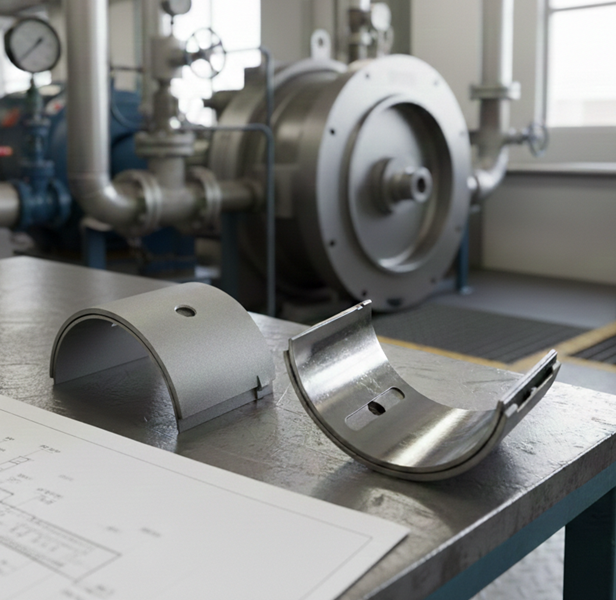

If the gap is too big, the best move is to replace the shell with a thicker one. Use an original FA1B56-A2-104287 radial bearing shell so the materials match perfectly. Sometimes you can add thin metal shims under the bearing seat for a tiny adjustment. Make sure those shims are high-quality metal that won't squish or rust.

If the gap is too small, you have to scrape the shell. Use a specialized scraper to take off a tiny bit of material from the inner surface. Go slow and measure often—you don't want to over-scrape and end up with a gap that is too big. If the shell is already looking rough, it's safer to just put in a new one.

4. Field Essentials: Making it Last

Before you adjust anything, check how the bearing seat fits the shell. It should be snug with no rust or wobbling. Also, keep an eye on the alignment (coaxiality). You don't want to fix the clearance but ruin the alignment in the process.

After you finish adjusting, check the clearance again using the Shaft Lift Method. Make sure the numbers stay steady. When you put the pump back together, do a no-load test run. Watch the heat and the vibration levels to prove the adjustment worked. Important: Never grind the shaft journal to fix the clearance. That ruins the surface finish and creates a huge safety risk.

5. Daily Maintenance: Keeping Things Steady

During your normal rounds, use a thermometer and a vibration pen to check on the FA1B56-A2-104287 radial bearing. If the numbers start creeping up, your clearance might be changing. We recommend a full clearance check every quarter.

Keep your oil clean. Dirt inside the bearing acts like sandpaper, wearing down the metal and widening the gap over time. Change your oil on schedule so it doesn't break down and lose its lubricating power.

Beyond managing radial bearing clearances, the stable operation of a feed pump depends on the precision fit of all auxiliary parts. Below is a list of core components commonly used for this model. To ensure perfect alignment and performance, you should always select parts that meet original factory specifications.

| Part Name | Model / Specification |

|---|---|

| Pump Spacer Sleeve | DG600-240-03-16 |

| Pump Gasket | DG600-240-05-10 |

| Seal Ring | HTHP-01-02-17-02 |

| Throttle Plug | HTHP-01-02-19-13 |

| Impeller Nut | FAID56-01-08B |

| Guide Vane | HPT200-330-04-14 |

| Pump Casing Wear Ring | FAID56-03-05 |

| Retaining Ring | DG600-240-07-02(4) |

| Pump Shaft | FA1D56-01-03A |

| Clamping Ring | HPT300-340Ⅲ-03-02 |

Conclusion: Accurate Control Protects the Unit

Managing the FA1B56-A2-104287 radial bearing comes down to knowing your pump's specific needs. Use the Shaft Lift Method, stick to the design standards, and adjust scientifically. That is how you stop failures before they start.

Need an original FA1B56-A2-104287 radial bearing, adjustment tools, or on-site help? Reach out to us. We provide the parts and the technical support to help you get the clearance exactly right.

HKCYT-2026-01-20

-

Why Re-using the HZB253-640-01-03 Locking Washer Risks Total Booster Pump Failure

Don't let bolts come loose. Learn how to check the HZB253-640-01-03 locking washer for fatigue, why you shouldn't re-use it, and how to install it right.02-04

-

Stop Pump Leaks: A Maintenance Guide for the HZB253-640-01-13 Shaft Sleeve

Prevent booster pump shutdowns. Learn how to spot HZB253-640-01-13 shaft sleeve erosion, pitting, and vibration issues before they ruin your mechanical seals.02-02

-

Stability Principles of the HD452D11 Sliding Bearing Under Extreme Dynamic Loads

Master the HD452D11 sliding bearing. Learn how its oil film and anti-vibration design protect feed pump shafts from wear under high-speed power plant loads.01-31

-

FA1D56A-00-1/4 Gasket: Fitting and Shock Protection for Pump Seal Chambers

Stop leaks in your feed pump seal water chamber. Learn how the FA1D56A-00-1/4 gasket matches your pump to resist pressure jumps and cavitation shocks.01-31

-

HPT200-300-05-01A-00 Oil Seal Assembly: Tips for Stopping Leaks After a Swap

Stop pump leaks for good. Learn how to install the HPT200-300-05-01A-00 oil seal assembly correctly, avoid common mistakes, and check for a perfect seal.01-28