Oil Slinger DG600-240-03-04: Installation Spots and Field Essentials

In the world of power plant maintenance, if your lubrication fails, your pump dies. It's that simple. The Oil Slinger DG600-240-03-04 is a small part with a big job: it keeps the oil where it belongs and protects the bearings from dirt. If you don't install it with precision, you're looking at bearing failure, leaks, and eventually, an unplanned outage.

For the DG600-240 feedwater pump, this slinger is a perfect fit, but only if you put it in the right spot. Here is the breakdown of where it goes and how to get the installation right the first time.

1. Where Does It Go? (The Design Logic)

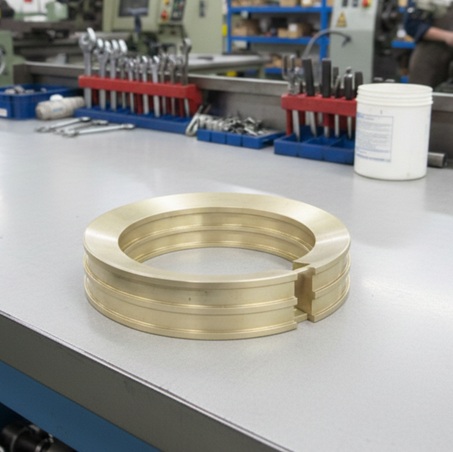

The standard home for the DG600-240-03-04 Oil Slinger is inside the pump's bearing housing. It sits on the rotor shaft, specifically on the shoulder between the rolling bearing and the shaft end seal. You have to push it right up against that shaft shoulder to lock it in place.

Why is it there? It has two main jobs:

- Lubrication: As the shaft spins, the slinger picks up oil and splashes it evenly across the bearing rollers and the shaft neck. Without it, you get dry friction and overheating.

- Protection: It acts like a spinning shield. It stops oil from leaking out toward the seals and keeps dust or steam from sneaking into the bearing box.

The Golden Rule: For this pump, the shaft shoulder is your anchor. Your concentricity needs to be within 0.02mm. If it's off-center, it will vibrate, wobble, and ruin the oil film.

2. Installation: The "Do's and Don'ts"

Installing the DG600-240-03-04 isn't about brute force. Follow the "Clean, Align, Check" rule.

A. Clean it First

Don't even think about installing a slinger in a dirty housing. Use a professional cleaning agent to get rid of old oil, metal shavings, or grit. The shaft surface roughness should be controlled at Ra 1.6μm or better.

B. Getting it on the Shaft (Hot vs. Cold)

- Hot Mounting: Usually the best way. Heat the slinger to 80-100°C using an induction heater for about 20 minutes. Don't go over 100°C or you might ruin the metal properties. Slide it on fast and let it cool naturally.

- Cold Mounting: Only if the fit is loose enough. Use a bit of high-temp grease and a proper sleeve. Never hit it directly with a hammer.

- The Fit: It should turn smoothly with the shaft. Your clearance should be between 0.03mm and 0.08mm.

C. The Final Double-Check

Before closing the housing, check the side gaps. There should be about 1.5mm to 2.5mm of space between the slinger and the bearing/seal. If the "run-out" wobble is more than 0.03mm, you need to reseat it.

3. Quality Counts: Why OEM Specs Matter

The Dongfang SRI DG600-240-03-04 Oil Slinger is built exactly to original factory drawings using high-strength alloy steel. Our tolerances are tight (within ±0.02mm), ensuring a 100% fit. In the field, our parts have helped teams extend maintenance cycles by over 30%.

4. Troubleshooting and Pro-Tips

If your bearing is running hot or you see oil leaking, check the following:

- Check for shift: Did the slinger move away from the shaft shoulder?

- Check for wear: Are there grooves or cracks on the ring surface?

- Check the gap: Is it wobbling during rotation?

Need a replacement? Stick with the genuine Dongfang SRI DG600-240-03-04. We also provide a full range of power plant spares including Directional Valve Seals (MG0011.19.01), Butterfly Valve Stems, and Carbon Rings.

HKCYT-2026-01-12

-

Stop Booster Pump Leaks: Master the HZB253-640-01-05 Oil Flinger Install

Stop lube oil leaks. Learn how to control the HZB253-640-01-05 oil flinger gap, why install direction matters, and how to match its life to your bearing overhaul.02-25

-

Why Re-using the HZB253-640-01-03 Locking Washer Risks Total Booster Pump Failure

Don't let bolts come loose. Learn how to check the HZB253-640-01-03 locking washer for fatigue, why you shouldn't re-use it, and how to install it right.02-04

-

Stop Pump Leaks: A Maintenance Guide for the HZB253-640-01-13 Shaft Sleeve

Prevent booster pump shutdowns. Learn how to spot HZB253-640-01-13 shaft sleeve erosion, pitting, and vibration issues before they ruin your mechanical seals.02-02

-

Stability Principles of the HD452D11 Sliding Bearing Under Extreme Dynamic Loads

Master the HD452D11 sliding bearing. Learn how its oil film and anti-vibration design protect feed pump shafts from wear under high-speed power plant loads.01-31

-

FA1D56A-00-1/4 Gasket: Fitting and Shock Protection for Pump Seal Chambers

Stop leaks in your feed pump seal water chamber. Learn how the FA1D56A-00-1/4 gasket matches your pump to resist pressure jumps and cavitation shocks.01-31