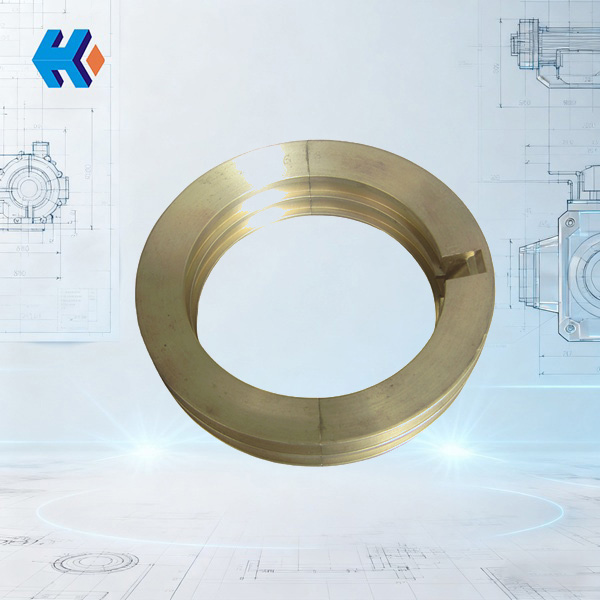

Electric Feedwater Pump Leaking Oil? DG600-240-03-04 Oil Slinger Ring to the Rescue!

In a 300MW thermal power unit, the DG600-240M electric feedwater pump is the heart of the boiler feed system—if it fails, the whole unit has to shut down. But what gives techs the biggest headache is lube oil leaking from the feedwater pump's bearing housing: a leak means the bearing is starved for oil and prone to burn-up, plus you have a messy cleanup, costing time and money. The key to solving this is actually a tiny component—the pump's DG600-240-03-04 Oil Slinger Ring.

Don't dismiss it as just a ring; it's designed to securely lock the lubricating oil inside the bearing housing and block out external contaminants, acting as the invisible bodyguard for the feedwater pump's stable operation.

I. This Ring Is Not Simple: Custom-Made for the DG600-240M Feedwater Pump

The DG600-240-03-04 oil slinger ring is not a generic part; it's specifically designed for the DG600-240M electric feedwater pump. It's fitted onto the pump shaft and rotates with it, performing two main jobs: first, it "slings" the lubricating oil trying to escape the bearing housing back inside, acting like a "goalkeeper" to prevent oil leakage; second, it blocks out external dust and moisture, stopping these contaminants from entering the bearing housing and causing bearing wear.

One plant used to have chronic oil leaks from their feedwater pump. After a long investigation, techs discovered they were using a reverse-engineered slinger ring—the size was slightly off, causing it to wobble during rotation, and oil leaked right through the gap. Once they switched to the DG600-240-03-04, the oil leak problem vanished. That's the benefit of using a dedicated part: it perfectly matches the pump's temperament, saving you a lot of unnecessary fiddling.

II. Three Strengths Make It the Techs' Go-To Choice

Why can the DG600-240-03-04 oil slinger ring handle the oil leak problem? The key is that its technical design is completely geared towards power plant conditions, hitting every pain point.

1. 1Cr17 Stainless Steel Material: Corrosion-Proof, Temperature-Resistant, and Durable

This oil slinger ring uses 1Cr17 Martensitic stainless steel. While it sounds technical, it basically means it's "tough": power plants have high humidity and oil contamination, where ordinary steel easily rusts, but this one doesn't mind. Even if it stays in a damp environment for a long time, it won't rust or warp. Its temperature resistance is excellent—it stays stable below 900 degrees Celsius, so the bearing housing temperature, which peaks at a few dozen degrees Celsius, is a piece of cake for it. Plus, the surface hardness is sufficient; turning at high speed with the pump shaft, it can withstand slight friction with the sleeve and seals without wearing out. It's good for two or three years of use, no problem.

2. Precision Machining: No Wobble on Installation, Reliable Sealing

We use high-precision CNC lathes for machining, so the ring's inner diameter, outer diameter, and thickness are strictly controlled—for instance, the fit clearance between the inner diameter and the pump shaft has an error of less than 0.01 mm. When installed, the slinger ring fits the pump shaft perfectly and rotates steadily without eccentric wobbling, which naturally prevents oil leakage. One tech mentioned that replacing this slinger ring requires no on-site grinding; you just grab it and install it, saving a lot of time.

3. Optimized Structure: Active Oil Slinging is Better Than Passive Sealing

The ring's external shape is specially designed. As it rotates with the pump shaft, it generates centrifugal force, acting like a small fan that "slings" the oil trying to escape back into the bearing housing. This active anti-leak design is much more reliable than passive seals that rely on rubber pads—rubber pads age easily, but this ring works by centrifugal force, meaning it keeps "guarding the gate" as long as it's spinning, requiring less maintenance.

III. Three Scenarios Where You Really Can't Do Without It

The DG600-240-03-04 oil slinger ring has a very high "utilization rate" in power plants, and techs must look for it in these three specific situations.

1. Planned Major Overhaul: A Mandatory Consumable

When the unit undergoes an A/B level overhaul, the feedwater pump must be fully inspected, and the oil slinger ring is a mandatory replacement part. According to the maintenance file package for 300MW units, regardless of whether the old slinger ring looks good, it must be replaced with a new one—because even without obvious wear after a few years of use, the material ages, and reuse risks oil leakage. Last year, one plant skipped the replacement during an overhaul, and it leaked half a year later, forcing another shutdown and replacement, causing a loss of generation.

2. Emergency Repair: Immediate Stock Saves Major Time

If the feedwater pump suddenly leaks oil and trips, it’s an emergency. One plant had a midnight oil leak from their feedwater pump. They traced it to a worn-out slinger ring. Luckily, they had the DG600-240-03-04 in their spare parts inventory. The techs replaced it in two hours and restored operation, avoiding major losses. Without immediate stock, waiting for a manufacturer to ship would take at least two days, and the losses would be huge.

3. Spare Parts Stocking: Must Be Stored with Complementary Parts

Power plant materials departments stock this slinger ring, but stocking it alone isn't enough; it must be stored with complementary parts—such as sleeves and sealing washers. Otherwise, if the complementary part is found to be damaged when replacing the slinger ring, the repair still can't be completed. The table below shows the slinger ring's "good partners" for techs to check when stocking.

IV. The Oil Slinger Ring's Complementary Partners Table: Replace Together for Peace of Mind

| No. | Part Model | Part Name | Cooperative Function with Slinger Ring | Applicable Scenario |

|---|---|---|---|---|

| 1 | DG600-240-04-2/04-05 | Pump Sleeve | Works with the slinger ring to form the sealing gap, assisting in "slinging oil" to prevent leaks | Feedwater Pump Shaft End Sealing System |

| 2 | DG600-240-04-06 | Sealing Washer | Fills the gap between the sleeve and slinger ring, preventing minor oil seepage | Sleeve and Slinger Ring Connection Point |

| 3 | DG600-240-03-21 | Pump Water Slinger Ring Nut | Fixes the slinger ring's position, preventing loosening or shifting during operation | Slinger Ring Installation and Fixation |

| 4 | DG600-240(V)M | O-Type Rubber Seal Ring | Seals the contact surface between the slinger ring and the bearing housing for double leak prevention | Slinger Ring and Bearing Housing Interface |

V. Choosing the Right Supplier Means Peace of Mind and Reliability

Although the DG600-240-03-04 is a small part, you must choose a professional supplier — Dongfang SRI can provide slinger rings that meet the original machine standards, and we can also supply the complementary parts like sleeves and sealing washers all together, saving you the trouble of sourcing from multiple places. Plus, we keep stock, so whether it's for overhaul preparation or emergency repair, we can ship immediately, eliminating slow logistics worries even for remote power plants.

One plant ordered slinger rings and complementary parts from us, and during the overhaul, they did the full kit replacement. The techs said it saved a lot of procurement time, and the installation went smoothly. The truth is, small parts in a power plant are often problematic if they are "non-matching." Finding the right supplier saves a lot of unnecessary work.

Ultimately, the DG600-240-03-04 oil slinger ring is one of those "small parts with a big job"—it solves the huge headache of feedwater pump oil leakage, ensuring the unit runs smoothly. If your 300MW unit uses the DG600-240M electric feedwater pump, take note of this slinger ring next time you do maintenance. Choosing the right one saves a lot of upkeep effort!

HKCYT-2025-10-29

-

Stop Booster Pump Leaks: Master the HZB253-640-01-05 Oil Flinger Install

Stop lube oil leaks. Learn how to control the HZB253-640-01-05 oil flinger gap, why install direction matters, and how to match its life to your bearing overhaul.02-25

-

Why Re-using the HZB253-640-01-03 Locking Washer Risks Total Booster Pump Failure

Don't let bolts come loose. Learn how to check the HZB253-640-01-03 locking washer for fatigue, why you shouldn't re-use it, and how to install it right.02-04

-

Stop Pump Leaks: A Maintenance Guide for the HZB253-640-01-13 Shaft Sleeve

Prevent booster pump shutdowns. Learn how to spot HZB253-640-01-13 shaft sleeve erosion, pitting, and vibration issues before they ruin your mechanical seals.02-02

-

Stability Principles of the HD452D11 Sliding Bearing Under Extreme Dynamic Loads

Master the HD452D11 sliding bearing. Learn how its oil film and anti-vibration design protect feed pump shafts from wear under high-speed power plant loads.01-31

-

FA1D56A-00-1/4 Gasket: Fitting and Shock Protection for Pump Seal Chambers

Stop leaks in your feed pump seal water chamber. Learn how the FA1D56A-00-1/4 gasket matches your pump to resist pressure jumps and cavitation shocks.01-31