Stability Principles of the HD452D11 Sliding Bearing Under Extreme Dynamic Loads

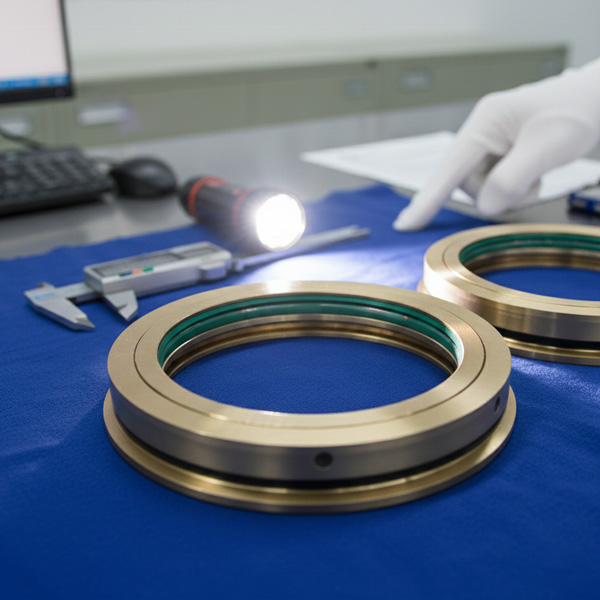

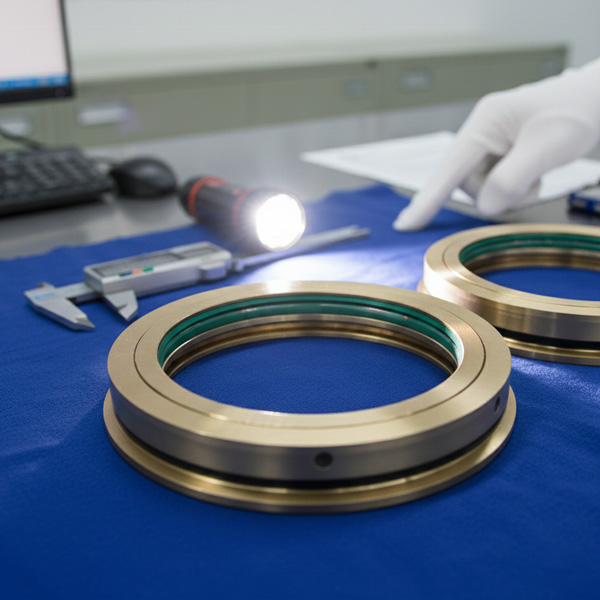

The HD452D11 sliding bearing is the main part that supports the shaft system in a feed pump. In power plants, these pumps run at very high speeds and always have some vibration. The bearing has to hold the weight of the shaft while taking hits from these vibrations to keep everything spinning smooth. It works by matching the speed and soaking up the shakes. With the right material, shape, and oil, the HD452D11 sliding bearing stops the shaft from wearing down or getting stuck, keeping the pump running safe.

1. Building for the Job: Materials and Shape

The materials used for the HD452D11 sliding bearing are picked just for high-speed and high-vibration work. We don't use basic metals; we use high-strength, wear-resistant alloys that are tough and don't get tired (fatigue) easily.

When the pump spins fast, the spot where the shaft touches the bearing gets very hot. The material must move that heat away fast so the metal doesn't get soft or wear out. Our original HD452D11 sliding bearing has high purity to move heat better and last longer. The shape is also made to be a perfect fit. The inside is cut exactly to match the pump shaft so the gap is just right—loose enough to spin but tight enough to stop the shaft from jumping around when it vibrates.

2. The Core Work: Oil Film and Balancing the Load

The HD452D11 sliding bearing stays stable because of the oil and the balance of force. Once the pump starts, lube oil is pushed into the gap to make a thin oil film.

This oil film is like a cushion. At high speeds, it stops the metal from touching so there is less friction. It also acts like a shock absorber for vibrations so the metal doesn't get hit directly. If you don't have enough oil, the HD452D11 sliding bearing will lock up and the pump will stop. Also, the internal design spreads the weight out evenly across the whole surface. This stops one spot from getting pushed too hard, which prevents cracks even when the pump is shaking.

3. Working Together: Parts that Support the Bearing

The HD452D11 sliding bearing can't do the job alone. It needs the pump shaft and thrust bearings to be in good shape, too. If those parts are off, the sliding bearing will take too much stress.

Here is a list of core parts that work with this bearing. Using original specs makes the HD452D11 sliding bearing much more reliable:

| Part Name | Model / Specification |

|---|---|

| Pump Shaft | FA1D56A-01 |

| Last Stage Guide Vane | DG600-240-04-14 |

| Circular Ring | FK5G32-04-11 |

| Secondary Impeller | FT10QA38M-03-02 |

| Double Suction Impeller | GNPD-HZB253-640A-01-01 |

| Balance Drum Bushing | FK5G32-04-08 |

| Thrust Bearing | FA1D56A-A1GB-10700-00 |

| Secondary Impeller (Alt) | 1FK5F32KM-03-03 |

| Thrust Bearing (Alt) | HPT300-340-06-00 |

| O-Ring | DG600-240-07-01(11) |

The precision of the pump shaft and the stability of the thrust bearing change how the HD452D11 sliding bearing handles the load. We can provide all these original parts so everything matches.

4. Fighting Vibration: Keeping the Bearing Safe

For high-vibration jobs, the HD452D11 sliding bearing has a special anti-vibration design. The outer ring has a buffer layer to soak up the energy from the shakes so the main body of the bearing stays safe.

The contact surface is ground very smooth. This keeps the oil film thick and stops the bearing from catching or stuttering when the vibration is high. The contact angle is also optimized to adjust itself to the vibration frequency. Our original HD452D11 sliding bearing gets an extra treatment to fight fatigue, meaning fewer cracks and a longer life even in the toughest conditions.

5. Daily Care: Making the Bearing Last

You have to check the lube system often. Make sure there is enough clean oil and change it on schedule. If dirt gets in the oil, it ruins the film and grinds down the HD452D11 sliding bearing. Clean oil is the most important thing for high-speed work.

Watch the bearing while it's running. Check the temperature and how much it's shaking. If the heat goes up fast or the vibration gets louder, stop the pump and find out why before the bearing locks up. Also, check the gaps every few months. Over time, the gap between the shaft and the HD452D11 sliding bearing might get too big. If that happens, the vibration will get worse, so you have to adjust it.

Conclusion: Smooth Support for Better Pumping

The HD452D11 sliding bearing works well because its material, shape, and oil film are all made to handle the speed and the shakes of a feed pump. By using a good oil cushion and a strong anti-vibration design, it gives the shaft the support it needs.

Need an original HD452D11 sliding bearing, pump shafts, or help with maintenance? Contact our team. We provide the best bearings and the technical support to keep your feed pump running steady and save you money on repairs.

HKCYT-2026-01-31

-

Stop Pump Leaks: A Maintenance Guide for the HZB253-640-01-13 Shaft Sleeve

Prevent booster pump shutdowns. Learn how to spot HZB253-640-01-13 shaft sleeve erosion, pitting, and vibration issues before they ruin your mechanical seals.02-02

-

Stability Principles of the HD452D11 Sliding Bearing Under Extreme Dynamic Loads

Master the HD452D11 sliding bearing. Learn how its oil film and anti-vibration design protect feed pump shafts from wear under high-speed power plant loads.01-31

-

FA1D56A-00-1/4 Gasket: Fitting and Shock Protection for Pump Seal Chambers

Stop leaks in your feed pump seal water chamber. Learn how the FA1D56A-00-1/4 gasket matches your pump to resist pressure jumps and cavitation shocks.01-31

-

HPT200-300-05-01A-00 Oil Seal Assembly: Tips for Stopping Leaks After a Swap

Stop pump leaks for good. Learn how to install the HPT200-300-05-01A-00 oil seal assembly correctly, avoid common mistakes, and check for a perfect seal.01-28

-

ID56-H75/95-00 Mechanical Seal: Spotting Leaks and Planning Repairs for Booster Pumps

Stop booster pump leaks. Learn how to spot early warning signs like heat and noise for the ID56-H75/95-00 mechanical seal to plan your repairs before a failure.01-23