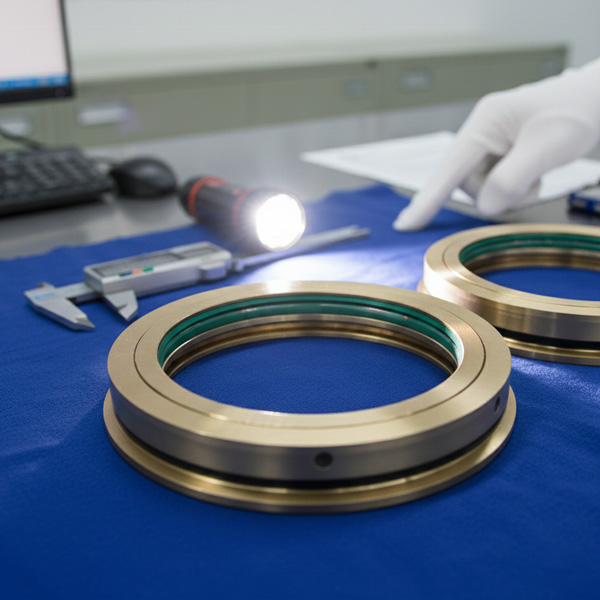

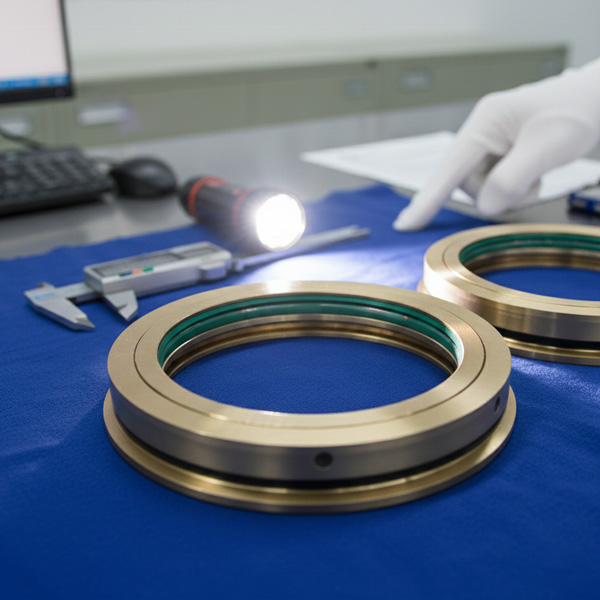

FA1D56A-00-1/4 Gasket: Fitting and Shock Protection for Pump Seal Chambers

The FA1D56A-00-1/4 sealing gasket is the main part that seals the water chamber for feedwater pump mechanical seals. When the pump runs, the water chamber gets small pressure jumps and cavitation hits. If the gasket doesn't match the pump body perfectly, it's going to leak. This ruins the mechanical seal and makes the pump shake. The whole point of the FA1D56A-00-1/4 gasket is to get a "perfect fit." By matching the shape and material exactly, it stops pressure waves and cavitation from breaking the seal.

1. Design Match: Getting the Shape and Material Right

The shape has to follow the water chamber lines exactly. The FA1D56A-00-1/4 gasket is custom-cut to match the size and curves of the seal chamber. There are no size mistakes. The edges are beveled so it sits deep in the chamber grooves. This means there are no gaps for water to push through when the pressure jumps.

The material is also picked for this job. We use a flexible seal material that is tough but still has some "give." It handles high pressure but can also change shape a little during a shock to soak up the hit. This keeps it tight against the pump at all times. Our original FA1D56A-00-1/4 gasket uses a special mix just for feed pump water chambers. Even the thickness is exactly right to give an even squeeze without putting too much stress on the metal.

2. The Install: Fitting it Right to Stop Leaks

You have to clean everything before you even start. Scrub the seal chamber and the gasket groove. Get all the oil, metal bits, and junk out of there. If there is dirt left, the gasket won't sit flat and it's going to leak later. If the metal has dents, fix those first.

Put the FA1D56A-00-1/4 gasket into the groove slowly. Make sure it stays flat with no folds or slips. Press the edges with your hand to be sure it's in tight all the way around. If one spot is loose, the pressure waves will find it and push through. Use a torque wrench to tighten the bolts in the right order. This stops the gasket from getting crushed too hard on just one side. Once it's tight, it should be a seamless fit that can handle any shock.

The FA1D56A-00-1/4 gasket works best when the other parts are also good. Here is a list of parts for this pump. Using original ones helps keep the pressure steady:

| Part Name | Model / Specification |

|---|---|

| Mechanical Seal | FA1D67-D |

| Seal Ring | HTHP-01-02-17-03 |

| O-Ring Seal | DG600-240-07-01(11) |

| External Oil Deflector | HPTMK-200-300-5S |

| O-Ring Rubber Seal | DG750-180-M-01 |

| Oil Seal | FK5G32-04-09 |

| Centrifugal Pump Oil Seal | FAID67 |

| Impeller Lock Nut | FA1D56A-04 |

| Radial Bearing | FA1D56-A2-104287 |

| Impeller Nut | FAID56-01-12A |

| Circular Ring | FK5G32-03-14 |

If parts like the seal ring or mechanical seal don't fit right, the water chamber pressure will bounce around. This puts a lot of load on the FA1D56A-00-1/4 gasket. We provide all these original parts so the whole pump matches up perfectly.

3. Shock Resistance: Handling Pressure Jumps and Cavitation

To stop small pressure jumps, the gasket must have no gaps and a good "bounce." When the pump vibrates, the pressure moves into the gasket. Because the FA1D56A-00-1/4 gasket fits perfectly against the metal, the water can't find a path out. The flexible material soaks up the shock so the seal faces don't pull apart for a split second.

Cavitation is harder because it hits fast and very strong. This can make a weak gasket come loose. The FA1D56A-00-1/4 gasket is very tough, so it won't break or lose its shape when this happens. Because the design matches the groove so well, it stays tight even after a big hit. In power plants, these shocks happen a lot, so having a gasket that matches the pump exactly is the most important thing.

4. Mistakes to Avoid: Keeping the Fit Tight

Never use a non-original gasket. If the size or material is even a little bit off, it won't fit right. It might look okay when you bolt it down, but it will leak as soon as the pressure jumps or cavitation starts. It might even ruin the metal surface of the water chamber.

Don't reuse an old gasket. Once a gasket is used once, it gets tired and loses its shape. It won't sit tight a second time, and it won't handle shocks anymore. Always put in a new FA1D56A-00-1/4 gasket every time you open the pump for a check-up. Also, check for leaks right after you tighten the bolts. If you see water, stop and find the problem before it gets worse.

Conclusion: A Perfect Match Stops Leaks

The FA1D56A-00-1/4 gasket works because it matches the feed pump body exactly. If you use the right original part and install it carefully, it will handle pressure jumps and cavitation without leaking. This keeps your pump running safe.

Need an original FA1D56A-00-1/4 gasket, pump parts, or help with installation? Contact us. We have the high-quality gaskets and the tech support you need to stop leaks in your seal water chamber.

HKCYT-2026-01-31

-

Stop Pump Leaks: A Maintenance Guide for the HZB253-640-01-13 Shaft Sleeve

Prevent booster pump shutdowns. Learn how to spot HZB253-640-01-13 shaft sleeve erosion, pitting, and vibration issues before they ruin your mechanical seals.02-02

-

Stability Principles of the HD452D11 Sliding Bearing Under Extreme Dynamic Loads

Master the HD452D11 sliding bearing. Learn how its oil film and anti-vibration design protect feed pump shafts from wear under high-speed power plant loads.01-31

-

FA1D56A-00-1/4 Gasket: Fitting and Shock Protection for Pump Seal Chambers

Stop leaks in your feed pump seal water chamber. Learn how the FA1D56A-00-1/4 gasket matches your pump to resist pressure jumps and cavitation shocks.01-31

-

HPT200-300-05-01A-00 Oil Seal Assembly: Tips for Stopping Leaks After a Swap

Stop pump leaks for good. Learn how to install the HPT200-300-05-01A-00 oil seal assembly correctly, avoid common mistakes, and check for a perfect seal.01-28

-

ID56-H75/95-00 Mechanical Seal: Spotting Leaks and Planning Repairs for Booster Pumps

Stop booster pump leaks. Learn how to spot early warning signs like heat and noise for the ID56-H75/95-00 mechanical seal to plan your repairs before a failure.01-23