FA1D56-01-08B Impeller Nut: Maintenance Tips and How to Spot Damage Early

The FA1D56-01-08B impeller nut is the main part that keeps the feedwater pump impeller locked in place. Since these pumps run at very high speeds, this nut has to handle a lot of axial force and constant vibration. If the nut is solid, the impeller stays in line. But if it fails, the impeller can move or get loose, which ruins the pump's efficiency and makes the whole unit unsafe. During your regular teardowns, you have to look at this nut very closely. Finding a small crack or a bit of wear early is the only way to stop a total pump breakdown.

1. Regular Maintenance: What to Look For

The first thing to worry about is the tightening force. Vibration from the pump will try to back the nut off, so you must use a torque wrench to check it. If the FA1D56-01-08B impeller nut is too loose, the impeller will move and start rubbing the pump casing. But if you over-tighten it, you might stretch the threads or even crack the nut body.

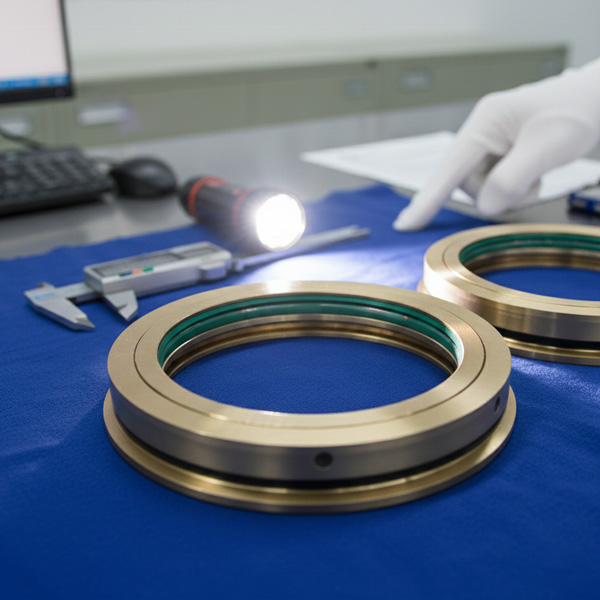

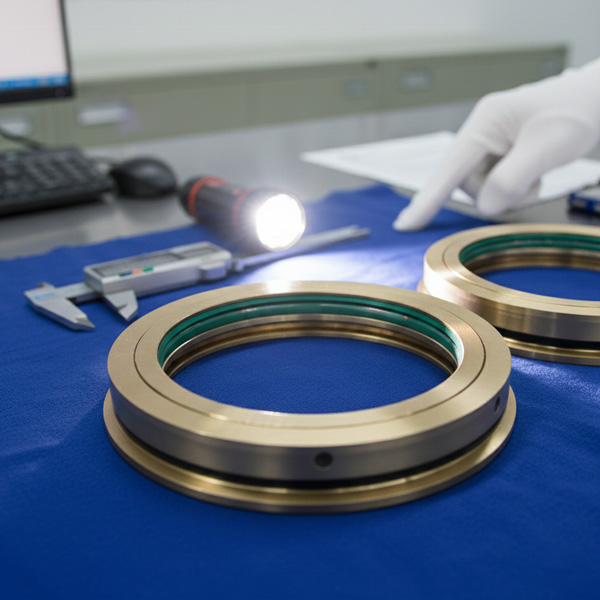

Take a good look at the threads. You are looking for wear, flat spots, or rust. Even a small scratch on the thread can turn into a big failure later on. Our original FA1D56-01-08B impeller nut uses high-precision threads made just for these heavy pump loads.

Clean the nut and the shaft surface really well. Get rid of old oil, rust, or metal shavings so the nut sits flat. If the surface is dented, the nut won't push evenly, and that leads to cracks. Also, don't reuse old locking washers or cotter pins. If those safety parts fail, the nut will loosen up fast. Always put in new ones.

2. Common Ways the Nut Fails

Stripped threads happen most of the time. The shock from starting the pump and the constant shaking wears the threads down until they can't hold the load anymore. This usually happens if the torque was wrong last time or if the threads were already a bit damaged.

Fatigue cracks are also a big risk. Constant stress from the spinning shaft creates tiny cracks at the corners of the nut. These grow until the FA1D56-01-08B impeller nut just snaps in half. When the nut breaks, the impeller goes loose, and that usually destroys the inside of the pump.

Loosening and shifting is a common headache. If the lock washer fails or the guy installing it was sloppy, the nut starts to back off. At first, you might just see the impeller move a tiny bit, but soon it starts running off-center and eats up the wear rings.

3. Damage Pre-diagnosis: Finding Problems While Running

You can actually find signs of trouble before you even open the pump. If the vibration gets high or you hear a weird rhythmic noise, the FA1D56-01-08B impeller nut might be coming loose. Check your axial vibration levels—if the nut is loose, the impeller will start "shuffling" back and forth on the shaft.

Check your oil reports, too. If the nut is grinding or cracking, tiny metal bits will show up in the lube oil. If the iron (Fe) levels suddenly go up, you need to check that nut. When you have the pump open, try to shake the impeller by hand. If it moves even a little, the nut is loose. Look for rust or tiny lines on the nut—if you see them, replace it.

4. Maintenance Protection: Making It Last Longer

Doing the installation right is the most important part. When you put the FA1D56-01-08B impeller nut back on, the threads must be clean and bone-dry. You can use a tiny bit of thread-locker to help it fight the vibration. Follow the torque chart from the manual—don't just guess by "feel."

Try not to "hard start" the pump if you don't have to. The huge torque hit from a fast start puts a lot of stress on the nut. Follow the slow ramp-up rules to keep the stress low. And like we said before, never reuse the old locking hardware. It’s a cheap part, but a failure costs a fortune.

5. Fitting Tips: Don't Use "Will-Fit" Parts

The FA1D56-01-08B impeller nut has its own specific size and strength. Do not try to use a "standard" nut from a local supplier. Those nuts don't have the right thread precision or the high-strength metal needed for a high-speed feed pump.

Our original FA1D56-01-08B impeller nut is made to fit the shaft and impeller perfectly. It can handle the shaking and the torque that cheap parts can't. To keep the whole pump safe, you should also check these other parts that work with the nut:

| Part Name | Model / Specification |

|---|---|

| Washer | FA1D56-03-24A |

| Spring | DG750-180-04-22 |

| Lock Nut | FK5G32-03-12 |

| Booster Pump Casing Stud | FA1D56-03-13 |

| Mechanical Seal (Component) | FA1D56A |

| O-Ring | HZB253-640 03-08 |

| Mechanical Seal | HZB253-6401143/8B1 |

| Bolt Protection Cap | DG750-180-01-09 |

| O-Ring (Alternative) | HZB253-640 03-08 |

| Secondary Impeller | HPT300-340II-03-03 |

All these parts have to work together. If the washer is wrong or the shaft is worn, it puts too much stress on the FA1D56-01-08B impeller nut, and that's when it starts to crack or come loose.

Conclusion: Good Maintenance Keeps the Pump Safe

Keeping the FA1D56-01-08B impeller nut in good shape is all about checking the torque and the thread quality. If you find the signs of a loose or cracked nut early and use the right original parts, the pump will run a long time without trouble.

Looking for an original FA1D56-01-08B impeller nut, locking pins, or some help with your pump overhaul? Contact us. We have the high-quality parts and the technical tips to help you get the job done right.

HKCYT-2026-01-22

-

Why Re-using the HZB253-640-01-03 Locking Washer Risks Total Booster Pump Failure

Don't let bolts come loose. Learn how to check the HZB253-640-01-03 locking washer for fatigue, why you shouldn't re-use it, and how to install it right.02-04

-

Stop Pump Leaks: A Maintenance Guide for the HZB253-640-01-13 Shaft Sleeve

Prevent booster pump shutdowns. Learn how to spot HZB253-640-01-13 shaft sleeve erosion, pitting, and vibration issues before they ruin your mechanical seals.02-02

-

Stability Principles of the HD452D11 Sliding Bearing Under Extreme Dynamic Loads

Master the HD452D11 sliding bearing. Learn how its oil film and anti-vibration design protect feed pump shafts from wear under high-speed power plant loads.01-31

-

FA1D56A-00-1/4 Gasket: Fitting and Shock Protection for Pump Seal Chambers

Stop leaks in your feed pump seal water chamber. Learn how the FA1D56A-00-1/4 gasket matches your pump to resist pressure jumps and cavitation shocks.01-31

-

HPT200-300-05-01A-00 Oil Seal Assembly: Tips for Stopping Leaks After a Swap

Stop pump leaks for good. Learn how to install the HPT200-300-05-01A-00 oil seal assembly correctly, avoid common mistakes, and check for a perfect seal.01-28