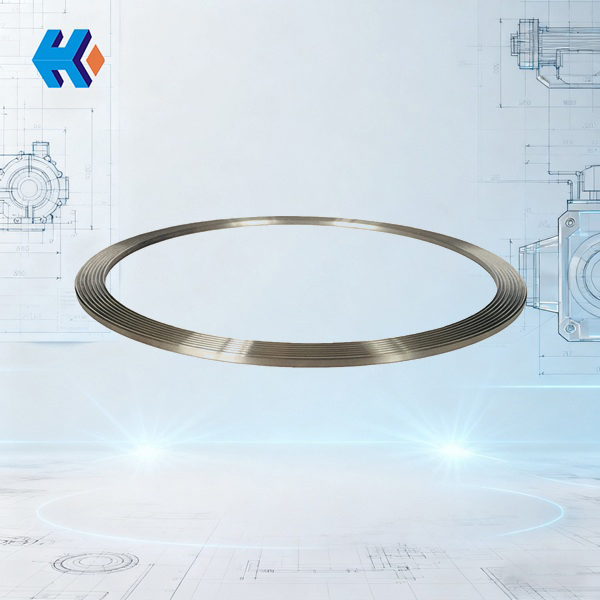

Locking Washer HZB253-640-01-14: The Booster Pump's Anti-Loosening Safety Pin

In the shaft system of the HZB253-640 boiler booster pump, the locking washer HZB253-640-01-14 is a small but absolutely essential component—a hidden little guy you cannot skip. It's just a thin disk placed between the lock nut and the mating faces of the impeller or shaft sleeve. Though thin, it has to handle the massive vibration and temperature swings when the pump runs at high speed. Its job is critical: when the impeller spins fast, this washer is what locks the nut down. It stops the nut from shaking loose due to vibration, preventing major failures like impeller runout and severe shaft vibration.

I. Exclusive Fit: Made Only for the HZB253-640 booster pump

This is not a generic washer. Its size and performance are made exactly according to the HZB253-640 booster pump's repair manual. The material is 1Cr18Ni9Ti austenitic stainless steel, which meets industry standards, making it rust-proof and heat-resistant. It fits between the lock nut HZB253-640-01-11 and components like the impeller HZB253-640-01-08, the double-suction impeller GNPD-HZB253-640A-01-01, and the shaft sleeve HZB253-640-01-13. These are its matching partners.

Its main job is securing the nut's pre-load force. When the booster pump runs, vibration and temperature changes try to loosen the nut. The washer uses its structure and strength to hold this force steady, maintaining the coaxial alignment of the shaft and impeller. The washers supplied by Dongfang SRI are checked for fit before shipping. No grinding or rework needed on site. Just install it and go.

II. Lock Reliability: Material + Structure + Performance

1Cr18Ni9Ti Stainless Steel: Durability is Key

The pump environment often hits 280°C. This washer handles it easily. It can even withstand short heat spikes up to 750°C. The material is rust-resistant, which is essential in humid power plants. Every batch from Dongfang SRI gets a material check to ensure no bad parts are used.

Mechanical Strength: No Breaking, Plenty of Spring

This washer has a tensile strength of ≥ 550 MPa, yield strength of ≥ 200 MPa, and elongation of ≥ 40%. When you tighten the nut, it won't break. When the pump vibrates, it can slightly deform to compensate for lost pre-load, keeping the anti-loosening effect long-term. Its anti-loosening security is over 30% better than standard stainless steel washers.

Tooth Structure: Mechanical Bite for a Solid Lock

The design is clever: The ring base has six evenly spaced locking teeth. They bite firmly into the surfaces of the nut and the secured component, creating a mechanical lock. Manufacturing is precise, with flatness error ≤ 0.02mm. It achieves over 99% contact with the mating surface. Every batch passes three checks: strength, size, and anti-loosening test, all following the repair manual.

III. System Partners: Anti-Loosening Isn't a Solo Act

The locking washer's effectiveness relies on other parts working with it. During overhaul, check all these components. Missing one can cause problems. Key partners include:

| Component Category | Product Name | Model | Function in System |

|---|---|---|---|

| Core Locking Parts | Locking Washer | HZB253-640-01-14 | Mechanical bite + spring compensation, locks nut pre-load |

| Lock Nut | HZB253-640-01-11 | Directly fastens component, works with washer to prevent loosening | |

| Secured Components | Impeller | HZB253-640-01-08 | Core rotating part, relies on washer for stable positioning |

| Shaft Sleeve | HZB253-640-01-13 | Protects pump shaft, works with washer for sealing and positioning | |

| Related Seals | O-ring | HZB253-640-02-01 | Failure of the washer can cause this seal to break |

IV. Service Life: When to Change and How to Use It

Daily Running: Stops 80% of Shaft Loosening Faults

In the HZB253-640 booster pumps of power plants, this washer is key to shaft stability. Some plant data shows that using it cut shaft loosening failures from 8% down to less than 1%. If the washer fails and the nut loosens, the impeller will spin off-center. The shaft shakes badly. O-rings will leak, and the pump shaft itself can be ruined.

Overhaul Mandatory Change: The 10,000 Hour Red Line

The repair manual is clear: After the booster pump runs for 10,000 accumulated hours, the washer must be replaced. Change it also if the teeth are worn, deformed, or if it is rusted during an overhaul. Dongfang SRI's washers match the original part size exactly. Just clean up the area and install. One plant reported changing our washer in under half an hour—much faster than dealing with non-standard parts.

Old Pump Upgrades: Low-Cost Way to Boost Security

Many older booster pumps use washers with poor heat resistance that always loosen. You don't need to change the entire fastening structure. Just upgrade to the HZB253-640-01-14 washer. Dongfang SRI can provide a full fastening solution, including the lock nut and stop washer, for a complete upgrade. One older plant extended their fastening system maintenance cycle from 8,000 hours to 15,000 hours after the upgrade.

V. Choosing the Right Part: Dongfang SRI Saves You Trouble

This washer looks simple, but choosing the wrong one causes huge problems. Dongfang SRI's locking washer HZB253-640-01-14 matches the original factory part in material, size, and performance. Every batch is tested. We have plenty in stock and can ship for emergency repairs the same day. Our technical team can help you decide if it needs replacing and guide correct installation—making sure the locking teeth bite properly and the torque is correct. We make sure a small washer doesn't cause a major failure.

Whether for routine changes, stocking for overhaul, or upgrading an old pump, Dongfang SRI is your single source. From the core washer to the full set of fastening spares, the quality is reliable, and the service is fast. Contact us anytime for needs or technical questions. Keep the booster pump's anti-loosening safety pin reliable.

HKCYT-2025-12-05

-

Stop Booster Pump Leaks: Master the HZB253-640-01-05 Oil Flinger Install

Stop lube oil leaks. Learn how to control the HZB253-640-01-05 oil flinger gap, why install direction matters, and how to match its life to your bearing overhaul.02-25

-

Why Re-using the HZB253-640-01-03 Locking Washer Risks Total Booster Pump Failure

Don't let bolts come loose. Learn how to check the HZB253-640-01-03 locking washer for fatigue, why you shouldn't re-use it, and how to install it right.02-04

-

Stop Pump Leaks: A Maintenance Guide for the HZB253-640-01-13 Shaft Sleeve

Prevent booster pump shutdowns. Learn how to spot HZB253-640-01-13 shaft sleeve erosion, pitting, and vibration issues before they ruin your mechanical seals.02-02

-

Stability Principles of the HD452D11 Sliding Bearing Under Extreme Dynamic Loads

Master the HD452D11 sliding bearing. Learn how its oil film and anti-vibration design protect feed pump shafts from wear under high-speed power plant loads.01-31

-

FA1D56A-00-1/4 Gasket: Fitting and Shock Protection for Pump Seal Chambers

Stop leaks in your feed pump seal water chamber. Learn how the FA1D56A-00-1/4 gasket matches your pump to resist pressure jumps and cavitation shocks.01-31