Beyond the Lid: Structural Load and Sealing Synergy in the HZB253-640-03-02 Pump Cover

The HZB253-640 booster pump is the pressure backbone of the boiler feed water system. When the end cover fails—whether it is oil leakage from the bearing chamber, excessive shaft vibration, or seepage from the sealing face—the consequences range from emergency maintenance to catastrophic damage to bearings and gearboxes. The End Cover HZB253-640-03-02 serves as the dual-core component for Support + Sealing. It must carry axial loads while holding the line against leaks. Selecting the right spares and installing them with precision is the only way to kill these failures at the root.

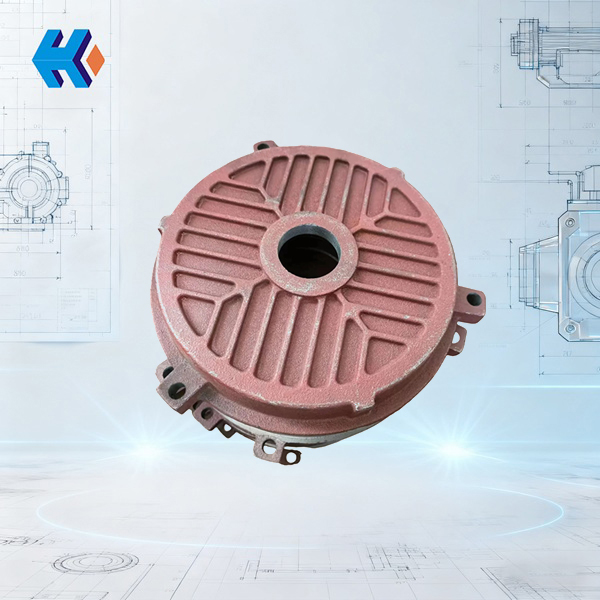

I. Product Role: The End-Point Command Center

The HZB253-640-03-02 end cover is much more than a simple lid. It is a core structural piece of the HZB253-640 booster pump. It manages sealing protection on one hand and axial support on the other. Working in tandem with the Wear Ring HZB253-640-03-04-00, Sealing Gaskets, and O-Rings, it forms a defense system that guards the bearing chamber and gearbox. Its precision directly dictates the coaxiality of the pump shaft and the overall stability of the feed water pressure.

To survive high temperatures, high pressures, and constant vibration, our end covers are forged from 2Cr13 Martensitic Stainless Steel. After tempering, the hardness is locked in at HB 240-280—strong enough to hold the axial load but tough enough to absorb high-frequency vibration without cracking. We provide the full one-stop kit, built strictly to original factory specs, ensuring zero-adjustment drop-in compatibility.

Core Matching Spares Checklist:

| Spare Part Name | Model / Spec | Role & Function |

|---|---|---|

| Wear Ring | HZB253-640-03-04-00 | Reduces friction between the shaft and end cover to prevent housing wear. |

| Sealing Gasket | HZB253-640-02-07/03-06 | Fills the gaps between the cover and pump body to block medium/oil leaks. |

| O-Ring | HZB253-640-03-08/09 | Fits the cover grooves to provide a static seal against fine seepage. |

| Mechanical Seal | HZB253-6401143/8B1 | The primary shaft-end seal; heat-resistant and wear-proof. |

| Spiral Wound Gasket | HZB253-640-03-24 | High-pressure sealing for the main connection between cover and casing. |

II. Core Advantages: Built for the Hot and High Reality

1. Toughened Material + Precise Heat Treatment

Using 2Cr13 stainless steel means you get natural corrosion resistance against high-temp water and lubricants. Following the Quench + High-Temp Temper process, we ensure the HB 240-280 hardness. This is the Goldilocks zone: it's hard enough to support the shaft loads but retains the ductility needed to survive the turbine hall's vibrations. This stops the cracking and warping that plague cheap, non-tempered covers.

2. High-Precision Machining: Zero Fitment Risk

Our end covers are machined to tolerances within ±0.015mm. The mounting holes and seal grooves are identical to the original factory manual. With a surface roughness of Ra ≤ 0.8μm, the mating surfaces are so smooth that the gaskets seal instantly without needing excess torque or messy sealants. All matching parts—from O-rings to spiral-wound gaskets—fit the grooves perfectly, so your crew doesn't waste time grinding or shimming.

3. Multi-Functional Integration

This part handles four jobs at once: Sealing, Support, Connection, and Protection. It seals the lubricant in and keeps dust out; it provides the axial stop for the bearings to keep the shaft centered; it connects the pump components for structural integrity; and it shields the precision internals from external hits. It is the definition of a mission-critical part.

III. Application Scenarios: When to Swap the Kit

- Major Overhaul (10,000-Hour Mark): Per the manual, this is the time to pull the end cover. If the seal grooves are worn or the body shows signs of warping, replace it with the full kit to reset the pump to factory standards.

- Troubleshooting Vibrations or Leaks: If you see oil weeping from the bearing chamber or the shaft is vibrating out of spec, the end cover's support or sealing has likely failed. A quick-swap of the cover and mech seal usually solves the issue in one go.

- Emergency Repairs: When a sudden failure occurs, every hour is lost generation. We maintain stock of the HZB253-640-03-02 and its gaskets to get your feed water system back online before the outage costs spiral.

- Life Extension for Older Pumps: For aging HZB units, the original covers often suffer from material fatigue. Replacing them with our upgraded 2Cr13 versions is a low-cost way to harden the pump for another decade of service.

Summary: Get the Support Right, Keep the Run Steady

The End Cover HZB253-640-03-02 is the hub of the booster pump's end-point. By choosing a high-quality cover and a perfectly matched spare kit, you aren't just fixing a leak—you are stabilizing the entire rotation. All our parts follow original technical standards to ensure your maintenance is fast and your operation is worry-free.

Need technical guidance on end cover fitment or help selecting the right gasket set? Contact us today. We provide the parts and the field-tested expertise to keep your booster pumps running at 100%.

HKCYT-2025-12-24

-

Stop Booster Pump Leaks: Master the HZB253-640-01-05 Oil Flinger Install

Stop lube oil leaks. Learn how to control the HZB253-640-01-05 oil flinger gap, why install direction matters, and how to match its life to your bearing overhaul.02-25

-

Why Re-using the HZB253-640-01-03 Locking Washer Risks Total Booster Pump Failure

Don't let bolts come loose. Learn how to check the HZB253-640-01-03 locking washer for fatigue, why you shouldn't re-use it, and how to install it right.02-04

-

Stop Pump Leaks: A Maintenance Guide for the HZB253-640-01-13 Shaft Sleeve

Prevent booster pump shutdowns. Learn how to spot HZB253-640-01-13 shaft sleeve erosion, pitting, and vibration issues before they ruin your mechanical seals.02-02

-

Stability Principles of the HD452D11 Sliding Bearing Under Extreme Dynamic Loads

Master the HD452D11 sliding bearing. Learn how its oil film and anti-vibration design protect feed pump shafts from wear under high-speed power plant loads.01-31

-

FA1D56A-00-1/4 Gasket: Fitting and Shock Protection for Pump Seal Chambers

Stop leaks in your feed pump seal water chamber. Learn how the FA1D56A-00-1/4 gasket matches your pump to resist pressure jumps and cavitation shocks.01-31