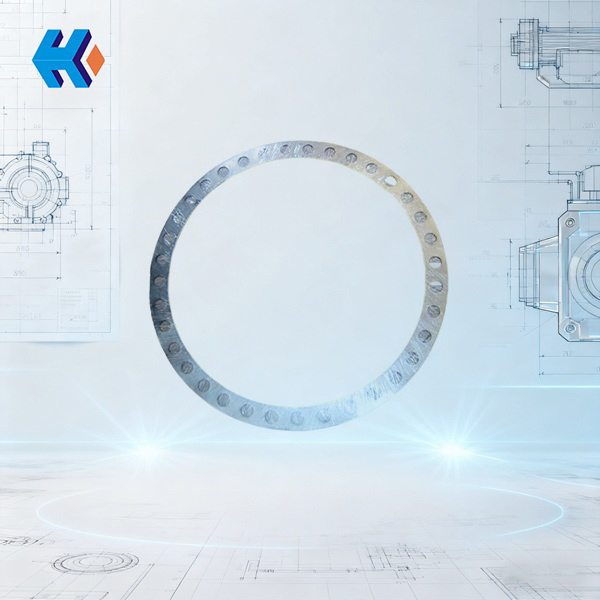

End Cover Gasket HZB253-640-03-01: A Reliable Sealing Solution for High-Temperature High-Pressure Booster Pump Casing

Booster Pump Casing End Cover Gasket HZB253-640-03-01: Ensuring Sealing Integrity Under Extreme Conditions

As a cornerstone sealing component in the power plant booster pump system, the Booster Pump Casing End Cover Gasket, model HZB253-640-03-01, directly dictates equipment stability and operational safety.

I. Introducing the Gasket

The HZB253-640-03-01 end cover gasket is the essential sealing element custom-engineered for the HZB253-640 model pre-pump. Its primary function is to seal the interface between the pump casing and the end cover, preventing the leakage of hot, high-pressure media and ensuring the booster pump can perform its critical transfer function within the station's steam-water cycle.

This gasket is part of a comprehensive sealing defense system, working in conjunction with components like the pre-pump O-ring (HZB253-640-03-09) and the metal-wound gasket for the pump cover (HZB253-640-03-24). Furthermore, during HZB253-640 pre-pump maintenance, it requires coordinated inspection and replacement alongside other seals, such as the feedwater pump non-drive end O-ring (HZB253-640-02-01) and the centrifugal pump shaft sleeve O-ring (HZB253-640-03-08), to ensure the entire system's sealing integrity is maintained. Its compatibility with wear parts like the pump shaft (HZB253-640-01-01) and the pre-pump wear ring (HZB253-640-03-04-00) further enhances the overall operational reliability and lifespan of the booster pump.

II. Technical Features and Advantages

(A) Premium Material: Exceptional Resistance to High Heat and Pressure

The HZB253-640-03-01 gasket is constructed from high-temperature, high-pressure rubber-asbestos sheet, a material strictly conforming to the GB/T 539-2008 standard. This composition provides outstanding tolerance for severe operating conditions.

It can withstand a continuous working temperature range of -50°C to +450°C, easily managing typical temperature fluctuations during power plant booster pump operation. Crucially, it is rated for an operating pressure of 6.0 MPa. Even when the system experiences transient pressure spikes, the gasket can briefly handle peak instantaneous temperatures, effectively preventing the gasket failures that plague lesser materials (such as the standard gasket HZB253-640-03-06 or the wire-reinforced gasket HZB253-640-03-07). This material offers a definite advantage in stability under extreme conditions.

Stop steam leaks dead in their tracks! Contact our experts to specify the right HZB253-640 gaskets for your next outage.

(B) Precision Manufacturing: Stable Sealing Performance

The gasket is produced using a precision machining process where dimensional accuracy and surface flatness are strictly controlled. This guarantees optimal adherence to the HZB253-640 pump casing and end cover, minimizing sealing gaps and fundamentally reducing the risk of media leakage.

Over prolonged operation, the inherent elasticity and resilience of the material effectively compensate for minor deformations of the pump casing caused by temperature changes. This maintains consistent sealing pressure, preventing seal failure due to equipment distortion and strongly supporting the long-term, reliable operation of the booster pump.

(C) Strong Compatibility: Easy Maintenance and Replacement

As a dedicated spare part for the HZB253-640 pre-pump, the gasket's dimensions and structure are perfectly matched to the pump's design. It allows for direct installation without any need for additional modification or fabrication.

During power plant overhauls, maintenance teams can quickly complete the gasket removal and replacement following the standard procedures outlined in the HZB253-640 Pre-Pump Maintenance Manual. Workers can simultaneously inspect and replace associated parts, such as the pre-pump O-ring (HZB253-640-03-09) and the shaft sleeve O-ring (HZB253-640-03-08), significantly accelerating the overhaul schedule and minimizing the economic impact caused by equipment downtime.

III. Application Scenarios

The HZB253-640-03-01 gasket is primarily used in energy facilities, including thermal power plants and nuclear power stations, equipped with the HZB253-640 model booster pump.

In thermal power generation, the pre-pump is vital for the boiler feedwater system, transferring high-temperature feedwater from the deaerator to the main feed pump. The gasket must constantly withstand this hot, high-pressure environment, ensuring zero leakage and guaranteeing a stable water supply to the boiler.

Similarly, in the auxiliary feedwater systems of nuclear power plants, the HZB253-640 pre-pump plays a key role. The reliable sealing performance of the HZB253-640-03-01 gasket is crucial for navigating the demanding operational environment of nuclear facilities, contributing to the integrity of the nuclear safety barrier.

Furthermore, during the routine maintenance and major overhauls of the HZB253-640 pre-pump, this gasket, being an easily worn sealing component, constitutes a major item in power plant maintenance procurement. The demand for this gasket, alongside other wear parts like the pre-pump wear ring (HZB253-640-03-04-00), forms a critical segment of the station's spare parts acquisition strategy.

Is your seal inventory optimized? Contact our procurement team for bulk pricing on all HZB253-640 critical spares today!

-

Stop Booster Pump Leaks: Master the HZB253-640-01-05 Oil Flinger Install

Stop lube oil leaks. Learn how to control the HZB253-640-01-05 oil flinger gap, why install direction matters, and how to match its life to your bearing overhaul.02-25

-

Why Re-using the HZB253-640-01-03 Locking Washer Risks Total Booster Pump Failure

Don't let bolts come loose. Learn how to check the HZB253-640-01-03 locking washer for fatigue, why you shouldn't re-use it, and how to install it right.02-04

-

Stop Pump Leaks: A Maintenance Guide for the HZB253-640-01-13 Shaft Sleeve

Prevent booster pump shutdowns. Learn how to spot HZB253-640-01-13 shaft sleeve erosion, pitting, and vibration issues before they ruin your mechanical seals.02-02

-

Stability Principles of the HD452D11 Sliding Bearing Under Extreme Dynamic Loads

Master the HD452D11 sliding bearing. Learn how its oil film and anti-vibration design protect feed pump shafts from wear under high-speed power plant loads.01-31

-

FA1D56A-00-1/4 Gasket: Fitting and Shock Protection for Pump Seal Chambers

Stop leaks in your feed pump seal water chamber. Learn how the FA1D56A-00-1/4 gasket matches your pump to resist pressure jumps and cavitation shocks.01-31