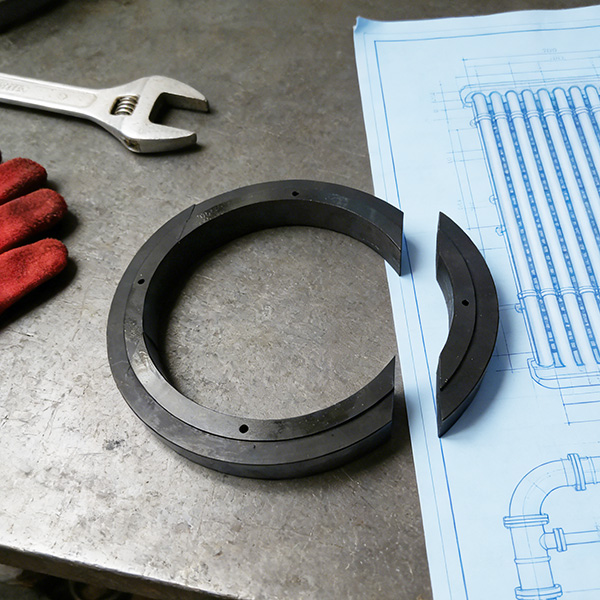

SA-182 F91 Superheater Block Valve Seal Ring: The Heavy-Duty Standard for HTHP Defenses

In utility boilers and waste heat systems, the superheaters and reheaters are the real hot zones. When you're pushing 600°C+ and ultra-high pressures, the sealing on your block valves (hydrotest valves) makes or breaks the unit's safety and heat rate. The SA-182 F91 Seal Ring, manufactured by Dongfang SRI, has become the go-to industrial grade choice. It's built from high-end alloy to stop the leaks that standard rings just can't handle.

I. Real-World Experience: A Tough Track Record in Spares

Dongfang SRI hasn't just popped up overnight; we've been at this since 2009. We're based in the industrial heart of Sichuan, specializing in the parts that keep power plants and steel mills running.

Our edge? We know how to work with the hard stuff—SA-182 F91, SA-213 T22, and ZG3Cr30Ni16Si2NRe. We don't just sell parts; we provide the precision-machined spares that engineers actually trust when a shutdown isn't an option.

II. The Gear: Sealing Solutions Built for the Heat

We've built our catalog around SA-182 F91 because it's the only way to handle real high-temp creep. From stop valve guts to boiler tubes, everything we make goes through the ringer—smelting, heat treatment, and 100% Non-Destructive Testing (NDT).

The Core Four Spares:

| Product Name | Material | The Why | Where It Goes |

|---|---|---|---|

| Superheater Seal Ring | SA-182 F91 | Micron-level precision that won't age or sag. | HT Superheaters (600°C+) |

| Four-Segment Ring | SA-182 F91 | Built to handle the breathing of thermal cycles. | Reheater Stop Valves |

| Pressure Plate Bolt | SA-182 F91 | High-toughness threads that don't snap or loosen. | HTHP Valve Assemblies |

| Self-Sealing Kit | SA-182 F91 | Low-maintenance, self-compensating seal. | Complex HTHP Scenarios |

III. Field Reports: Three Times Our Spares Saved the Day

Case 1: 300MW Unit—Kicking the Steam Leaks

- The Problem: A 300MW plant was losing steam at the superheater stop valves. Thermal efficiency was tanking and the safety guys were worried.

- The Fix: Dongfang SRI swapped in a full set of F91 components—rings, bolts, and self-seals. We machined them to a micron-fit so they seated perfectly.

- The Result: No more leaks. Heat rate jumped 3%. The gear has been running for 2 years without a hiccup, and we're expecting an 8-year service life now.

Case 2: Waste Heat Boiler—Saving the Pipes

- The Problem: Standard carbon steel tubes were getting eaten alive in a 550°C flue gas stream.

- The Fix: We moved them to SA-213 T22 tubes with a special polished inner wall. It creates a protective oxide skin that stops corrosion in its tracks.

- The Result: These pipes are lasting 3 to 5 times longer than the old ones. Plus, the plant is recovering way more heat since the exhaust temp dropped by over 100 degrees.

Case 3: Biomass Plant—Fighting the Abrasion

- The Problem: Biomass fuel is basically sandpaper. Standard cast iron coal ports were getting punctured every 6 months.

- The Fix: We cast a custom port using ZG3Cr30Ni16Si2NRe (Rare-Earth alloy). We beefed up the high-impact zones where the fuel hits hardest.

- The Result: We're 18 months in and still going strong—3x the life of the old iron. Maintenance downtime is down 60%.

The Bottom Line: Better Spares, Better Run-Time

The SA-182 F91 Seal Ring isn't just a piece of metal—it's the result of strict material choice and precision machining. At Dongfang SRI, we keep the focus on fit and forget reliability. Whether it's power, steel, or petrochem, we build the defenses your equipment needs to stay online.

Need a real solution for your next outage? Don't settle for good enough spares. Get the F91 gear that's built for the 600°C line. Contact Dongfang SRI and let's talk specs.

HKCYT-2025-12-26

-

Stop Booster Pump Leaks: Master the HZB253-640-01-05 Oil Flinger Install

Stop lube oil leaks. Learn how to control the HZB253-640-01-05 oil flinger gap, why install direction matters, and how to match its life to your bearing overhaul.02-25

-

Why Re-using the HZB253-640-01-03 Locking Washer Risks Total Booster Pump Failure

Don't let bolts come loose. Learn how to check the HZB253-640-01-03 locking washer for fatigue, why you shouldn't re-use it, and how to install it right.02-04

-

Stop Pump Leaks: A Maintenance Guide for the HZB253-640-01-13 Shaft Sleeve

Prevent booster pump shutdowns. Learn how to spot HZB253-640-01-13 shaft sleeve erosion, pitting, and vibration issues before they ruin your mechanical seals.02-02

-

Stability Principles of the HD452D11 Sliding Bearing Under Extreme Dynamic Loads

Master the HD452D11 sliding bearing. Learn how its oil film and anti-vibration design protect feed pump shafts from wear under high-speed power plant loads.01-31

-

FA1D56A-00-1/4 Gasket: Fitting and Shock Protection for Pump Seal Chambers

Stop leaks in your feed pump seal water chamber. Learn how the FA1D56A-00-1/4 gasket matches your pump to resist pressure jumps and cavitation shocks.01-31