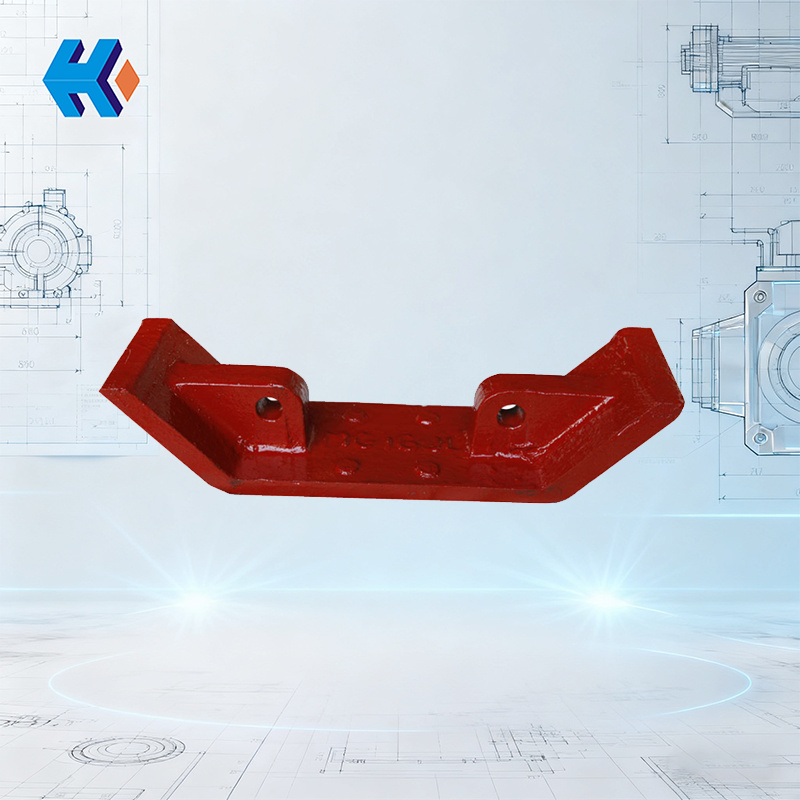

Introducing High-Performance Wear Plate 21MG30.11.09.89 for ZGM Series Medium-Speed Mills

Strategic Component Upgrade Drastically Extends Maintenance Cycles and Reduces Downtime in Power Plants

A new line of premium spare parts is set to transform the operational strategy for power generation facilities. The ZGM Series Medium-Speed Coal Mill Wear Plate 21MG30.11.09.89 (also called Anti-Abrasion Liner) are high-performance components specifically engineered to enhance the wear resistance of critical areas within the mill.

These wear plates utilize meticulously selected 16Mn premium wear-resistant steel and incorporate precision manufacturing with rigorous heat treatment technology. They are designed to provide long-lasting, reliable protection for core components such as the grinding table, mill casing, and classifier body. By effectively prolonging the equipment's overhaul period, these liners significantly reduce maintenance costs and minimize downtime losses associated with the frequent replacement of consumables, making them a strategic choice for power plants dedicated to long-term, stable operation of their pulverizing systems.

Technical Features and Advantages

1. Comprehensive Protection and Precision Matching

- Full Coverage Design: Provides a complete wear-prevention solution covering all easily worn areas inside the coal mill, including casing wear plates, grinding table wear plates, classifier wear plates, and roller seal zone wear plates, ensuring all-around protection.

- High-Precision Manufacturing: Utilizes CNC plasma cutting and precise bending/forming processes to guarantee that the dimensions, curvature, and bolt hole positions of every wear plate perfectly match the original structure of various ZGM series mill models. This ensures easy installation, tight fitting, and zero operational interference.

2. Superior Material Science and Wear Resistance

- Core Material: The main body uses 16Mn (16 Manganese) low-alloy, high-strength steel. This material offers excellent weldability and impact toughness, which is further enhanced through strengthening treatment to achieve superior strength and wear resistance. This provides an optimal balance of performance and cost-effectiveness, making it an ideal material for wear plates.

- Wear Enhancement (Optional): Based on specific client coal characteristics (e.g., highly abrasive conditions), enhanced solutions are available. These include surface hard-facing with wear-resistant weld beads or composite wear-resistant ceramic layers, multiplying the material's resistance to erosive wear in critical areas and significantly extending service life.

3. Excellence in Engineering and Quality Assurance

- Optimized Structural Design: The wear plate design accounts for material flow dynamics, reducing vortex and turbulent flow to structurally lower the wear rate. Ample wear allowance is also pre-designed into the components.

Significant Economic Benefits

By extending the replacement cycle, the product directly reduces the frequency of plant overhauls, lowers spare parts procurement costs, and decreases labor input. This translates directly into substantial savings and increased unit availability.

Application Scenarios

As a core wear-resistant component, this product is widely applicable in the following scenarios:

- Equipment Maintenance and Replacement: Ideal for scheduled overhauls and maintenance of ZGM series medium-speed coal mills (such as ZGM95, ZGM113, ZGM133, etc.) in major power plants, serving as a critical spare part during planned outages and emergency repairs.

- Operating Condition Adaptation: Suitable for pulverizing systems in all types of coal-fired power plants, effectively protecting the equipment casing and internal structures from continuous abrasive wear caused by coal dust and ash content.

-

Stop Booster Pump Leaks: Master the HZB253-640-01-05 Oil Flinger Install

Stop lube oil leaks. Learn how to control the HZB253-640-01-05 oil flinger gap, why install direction matters, and how to match its life to your bearing overhaul.02-25

-

Why Re-using the HZB253-640-01-03 Locking Washer Risks Total Booster Pump Failure

Don't let bolts come loose. Learn how to check the HZB253-640-01-03 locking washer for fatigue, why you shouldn't re-use it, and how to install it right.02-04

-

Stop Pump Leaks: A Maintenance Guide for the HZB253-640-01-13 Shaft Sleeve

Prevent booster pump shutdowns. Learn how to spot HZB253-640-01-13 shaft sleeve erosion, pitting, and vibration issues before they ruin your mechanical seals.02-02

-

Stability Principles of the HD452D11 Sliding Bearing Under Extreme Dynamic Loads

Master the HD452D11 sliding bearing. Learn how its oil film and anti-vibration design protect feed pump shafts from wear under high-speed power plant loads.01-31

-

FA1D56A-00-1/4 Gasket: Fitting and Shock Protection for Pump Seal Chambers

Stop leaks in your feed pump seal water chamber. Learn how the FA1D56A-00-1/4 gasket matches your pump to resist pressure jumps and cavitation shocks.01-31