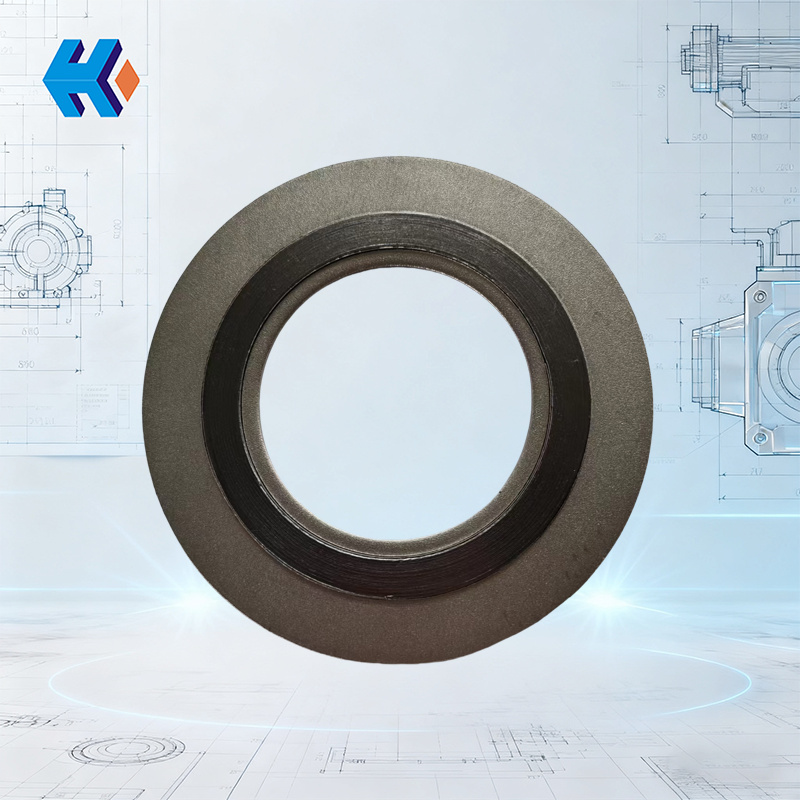

Steam Turbine Metallic Serrated Gaskets - High Performance Sealing for Power Generation

I. Product Overview

The Steam Turbine Metallic Serrated Gasket is a critical sealing element used in various flange connections within steam turbine systems. Its unique serrated structure and metallic composition enable it to deliver reliable sealing performance under high-temperature and high-pressure conditions, effectively preventing the leakage of steam, gas, or liquid media. These metallic serrated gaskets are widely applied in key areas of the turbine, including the High-Pressure (HP) cylinder, Intermediate-Pressure (IP) cylinder, steam guide pipes, and main steam valves, making them essential accessories for ensuring the safe and efficient operation of the steam turbine.

II. Product Features

Exceptional Sealing Performance

- Multi-Barrier Seal: Utilizing precision machining, the serrated structure of the gasket intimately conforms to the flange sealing surface, forming multiple sealing barriers to effectively prevent media leakage.

- Elastic Deformation: When compressed, the serrated gasket undergoes elastic deformation, further enhancing the sealing effect. It maintains excellent sealing performance even under extreme conditions of high pressure and high temperature.

High-Temperature and High-Pressure Resistance

- Premium Materials: Selected from high-quality stainless steel materials such as 0Cr18Ni10Ti, 1Cr18Ni9Ti, 316L, etc. These materials exhibit superior resistance to high temperatures and corrosion, capable of withstanding the harsh environments within operating steam turbines.

- Enhanced Strength: Through special heat treatment processes, the material's strength and toughness are further improved, ensuring the gasket resists deformation or damage during long-term operation.

Multiple Material Options

- Versatility: We offer serrated gaskets in various materials, including but not limited to 0Cr18Ni10Ti, 1Cr18Ni9Ti, 316L, 06Cr19Ni10, to meet diverse operating conditions and media requirements.

- Custom Application: Different materials are suitable for specific temperature, pressure, and media environments, allowing users to select the appropriate gasket material based on their exact needs.

Simple Installation and Maintenance

- Ease of Use: The structural design facilitates easy installation and removal, allowing users to conveniently mount the gasket in flange connections.

- Support: Detailed installation and maintenance guidelines are provided to ensure users correctly install and utilize the serrated gaskets, minimizing sealing failure caused by improper installation.

III. Product Applications

Steam turbine metallic serrated gaskets are extensively used across various parts of the power plant steam turbine system, including but not limited to:

- HP Cylinder Inlet Pipe: HP Cylinder Inlet Pipe Serrated Gasket (0Cr18Ni10Ti)

- IP Cylinder Main Steam Pipe: IP Cylinder Main Steam Pipe Serrated Gasket (0Cr18Ni10Ti)

- Main Steam Valve Cover: Main Steam Valve Cover Stainless Steel Serrated Gasket (1Cr18Ni9Ti)

- Steam Guide Pipe Flange: Steam Guide Pipe Flange Stainless Steel Serrated Gasket (1Cr18Ni9Ti)

- Control Valve Cover: Control Valve Cover Stainless Steel Serrated Gasket (1Cr18Ni9Ti)

- HP Steam Guide Pipe: HP Steam Guide Pipe Serrated Gasket (0Cr18Ni10Ti)

- IP Steam Guide Pipe: IP Steam Guide Pipe Serrated Gasket (0Cr18Ni10Ti)

These areas demand extremely high sealing performance, and the metallic serrated gasket effectively prevents media leakage, ensuring the safe operation of the steam turbine system.

IV. Installation and Maintenance

Installation Precautions

- Inspection: Before installation, carefully check the gasket's appearance and dimensions to ensure it is free from deformation, damage, or defects.

- Cleaning: Clean the flange sealing surfaces, removing oil, rust, and debris to ensure the sealing face is clean and smooth.

- Procedure: Install the serrated gasket following the correct sequence and method, avoiding forced installation that could damage the gasket.

- Tightening: Tighten the connecting bolts according to the specified torque and sequence, ensuring uniform tightening force to prevent deformation or leakage of the gasket sealing face due to uneven bolt load.

Maintenance and Upkeep

- Routine Check: Regularly check the sealing performance of the serrated gasket, observing the flange connection for any signs of media leakage. Address issues promptly if found.

- Bolt Integrity: Periodically check connecting bolts for looseness; tighten them immediately if necessary.

- Overhaul Inspection: During turbine shutdown for overhaul, conduct a comprehensive inspection and maintenance of the serrated gaskets, including cleaning the sealing surfaces and checking for wear. Replace the gaskets if necessary.

V. Quality Commitment

Our company implements strict quality control and inspection systems for the quality of Steam Turbine Metallic Serrated Gaskets. From raw material procurement to finished product delivery, every process undergoes rigorous quality inspection, ensuring product quality complies with national and industry standards.

If you are interested in our Steam Turbine Metallic Serrated Gaskets or have any inquiries, please feel free to contact us at any time. We will provide you with detailed product information, technical support, and after-sales service.

-

Stop Booster Pump Leaks: Master the HZB253-640-01-05 Oil Flinger Install

Stop lube oil leaks. Learn how to control the HZB253-640-01-05 oil flinger gap, why install direction matters, and how to match its life to your bearing overhaul.02-25

-

Why Re-using the HZB253-640-01-03 Locking Washer Risks Total Booster Pump Failure

Don't let bolts come loose. Learn how to check the HZB253-640-01-03 locking washer for fatigue, why you shouldn't re-use it, and how to install it right.02-04

-

Stop Pump Leaks: A Maintenance Guide for the HZB253-640-01-13 Shaft Sleeve

Prevent booster pump shutdowns. Learn how to spot HZB253-640-01-13 shaft sleeve erosion, pitting, and vibration issues before they ruin your mechanical seals.02-02

-

Stability Principles of the HD452D11 Sliding Bearing Under Extreme Dynamic Loads

Master the HD452D11 sliding bearing. Learn how its oil film and anti-vibration design protect feed pump shafts from wear under high-speed power plant loads.01-31

-

FA1D56A-00-1/4 Gasket: Fitting and Shock Protection for Pump Seal Chambers

Stop leaks in your feed pump seal water chamber. Learn how the FA1D56A-00-1/4 gasket matches your pump to resist pressure jumps and cavitation shocks.01-31