38CrMoAlA Material —— A Breakthrough Application in High-Temperature Superheater Block Valve Liners

Industry Context: The Urgent Need for High-Temperature Component Material Upgrades

Boilers are the thermal energy heart of critical industrial sectors like power generation, chemicals, and metallurgy. Their safe and stable operation directly dictates production efficiency and facility safety. The high-temperature superheater system, in particular, is the zone of highest temperature (often exceeding 600°C) and pressure. Components here must withstand extreme thermal and pressure shock over long periods.

The block valve liner, a seemingly small but crucial interface part, is especially challenged: it must provide sealing isolation between the pipe and the block valve while simultaneously resisting severe high-temperature abrasion and corrosive media. Traditional materials frequently fail due to insufficient performance, leading to leaks, cracking, and millions in annual maintenance losses for companies. Is premature failure costing you a fortune? Upgrade your liners now—contact us to find out how!

"We used to rely on standard alloy steel liners, which forced us to shut down for replacement every three months on average. This not only hampered our production schedule but posed a safety risk," states Engineer Wang, Equipment Department Director at a major thermal power plant. The material inadequacy of the superheater block valve liner has become a critical "pain point" restricting long-term boiler operation.

Component Analysis: The Synergistic Protection of the Valve and Liner

According to industrial equipment experts, the high-temperature superheater block valve acts as the boiler system's "emergency gate." It must rapidly seal off superheater piping during maintenance, start-up/shutdown, or pipeline failures, preventing high-temperature steam leaks.

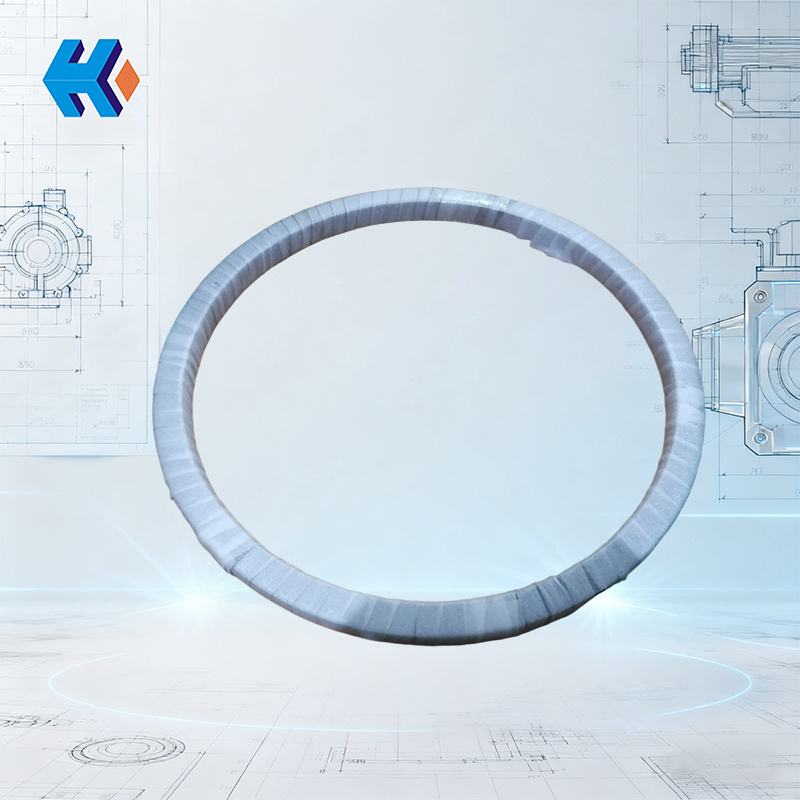

The liner, functioning as a "cushioning protector" between the valve and the pipe, is installed at the sealing and contact interfaces, performing three critical functions: First, it fills the sealing gap to prevent high-temperature steam penetration. Second, it isolates the block valve from direct pipe friction, minimizing wear. Third, it absorbs thermal expansion and contraction stresses resulting from temperature fluctuations, preventing component deformation.

"Though small, the liner is the 'safety barrier' of the high-pressure, high-temperature system," emphasizes Professor Li, a committee member of the Materials Branch of the Chinese Mechanical Engineering Society. Liner failure can trigger a cascade of issues, including steam leaks and pipe corrosion, potentially leading to boiler trips. Therefore, material selection must balance four core requirements: sealing performance, wear resistance, heat resistance, and anti-fatigue strength.

Material Breakthrough: The Five Performance Advantages of 38CrMoAlA

(1) High Surface Hardness and Abrasion Resistance

After the nitriding process, 38CrMoAlA's surface hardness reaches HV 950–1200 (equivalent to HRC 65–70)—three to four times that of ordinary carbon steel. This effectively withstands the frictional loss between the block valve and the pipe, extending the liner's service life from mere months to over two years.

(2) Exceptional Thermal Stability

The nitrided layer maintains stable hardness below 600°C. It resists hardness drop or cracking, even during the sudden temperature changes experienced during boiler start-up and shutdown, making it perfectly suited for the harsh superheater environment.

(3) Enhanced Corrosion Resistance

The addition of 1.35–1.65% chromium and 0.70–1.10% aluminum creates a dense, protective oxide film. This film combats corrosive media found in high-temperature steam, mitigating internal pipe wall corrosion risks.

(4) Reliable Mechanical Properties

The material boasts a tensile strength of ≥ 980 MPa, yield strength of ≥ 835 MPa, paired with an elongation of ≥ 14% and impact energy of ≥ 71 J. This mechanical robustness ensures the liner resists deformation or fracture under high-pressure impact, meeting long-term load-bearing demands.

(5) Excellent Processing Adaptability

38CrMoAlA can be reliably shaped using standard machining methods like turning and milling. Its superior weldability allows for easy customization of liner sizes for various boiler models, simplifying the manufacturing process.

Cross-Sector Application: A "Material Rising Star" from Boiler to Multi-Industry Use

Beyond the boiler superheater valve liner, the comprehensive performance advantages of 38CrMoAlA have led to its widespread adoption across several industrial fields:

- Mechanical Engineering: Used to manufacture inner rings for large bearings, high-precision gears, and transmission shafts, solving the premature wear and short lifespan issues of traditional materials.

- Automotive Industry: A key material for engine turbocharger components and crankshafts, well-suited for the high-temperature, high-pressure operating environment of modern engines.

- Petrochemical Sector: Utilized in the production of high-temperature oil pipelines and reactor sealing components, offering resistance to corrosion from crude oil and chemical media.

"Our company's 38CrMoAlA-based products already hold a 35% market share in the automotive turbocharger component sector," notes Mr. Zhang, director of a specialty steel manufacturing enterprise. As industrial equipment demands higher material performance, the market demand for this material is growing at an annual rate of 20%.

Industry Outlook: Specialty Steel Powers Industrial Equipment Upgrades

"The application of 38CrMoAlA in the high-temperature superheater block valve liner is a prime example of specialty steel empowering the upgrade of traditional industrial equipment." With the advancement of Industry 4.0 and smart manufacturing, more high-performance specialty steels—such as ceramic-matrix composites resistant to temperatures over 1000°C and highly corrosion-resistant Hastelloy alloys—will be integrated into core equipment components. This continuous material evolution will further enhance the safety, stability, and economic viability of industrial operations.

-

Stop Booster Pump Leaks: Master the HZB253-640-01-05 Oil Flinger Install

Stop lube oil leaks. Learn how to control the HZB253-640-01-05 oil flinger gap, why install direction matters, and how to match its life to your bearing overhaul.02-25

-

Why Re-using the HZB253-640-01-03 Locking Washer Risks Total Booster Pump Failure

Don't let bolts come loose. Learn how to check the HZB253-640-01-03 locking washer for fatigue, why you shouldn't re-use it, and how to install it right.02-04

-

Stop Pump Leaks: A Maintenance Guide for the HZB253-640-01-13 Shaft Sleeve

Prevent booster pump shutdowns. Learn how to spot HZB253-640-01-13 shaft sleeve erosion, pitting, and vibration issues before they ruin your mechanical seals.02-02

-

Stability Principles of the HD452D11 Sliding Bearing Under Extreme Dynamic Loads

Master the HD452D11 sliding bearing. Learn how its oil film and anti-vibration design protect feed pump shafts from wear under high-speed power plant loads.01-31

-

FA1D56A-00-1/4 Gasket: Fitting and Shock Protection for Pump Seal Chambers

Stop leaks in your feed pump seal water chamber. Learn how the FA1D56A-00-1/4 gasket matches your pump to resist pressure jumps and cavitation shocks.01-31