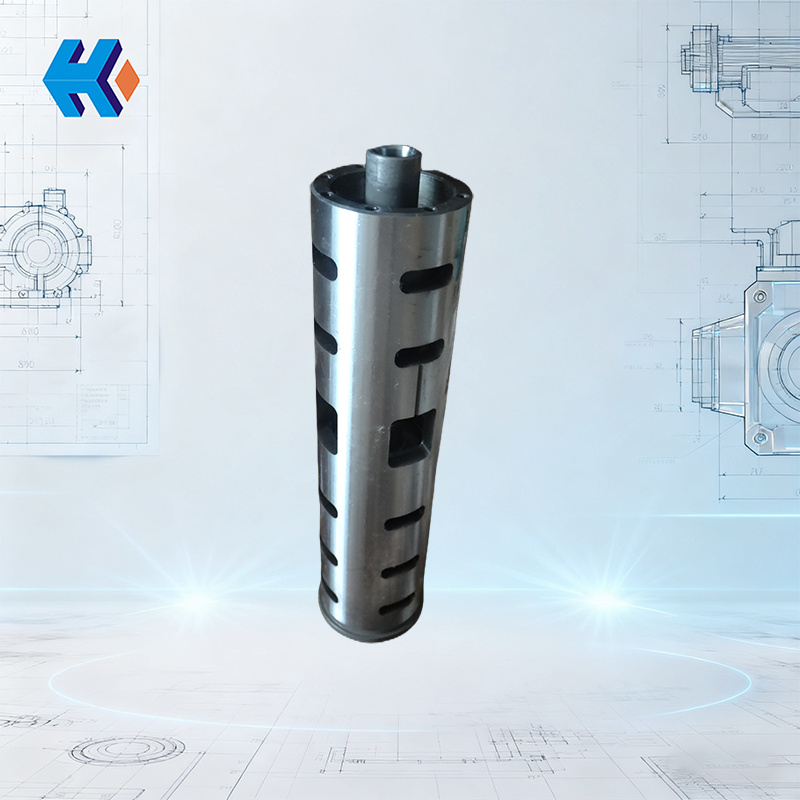

Steam Turbine Oil Valve Pilot Spool (Throttle/Governor Valve Spool)

I. Product Overview

The Steam Turbine Oil Valve Pilot Spool is a core control element in the turbine's governing system. It is designed to receive control signals from the governor or electro-hydraulic converter (EHC). Through the axial displacement of the spool, it alters the flow area of the oil ports, achieving precise regulation of the control oil flow and pressure. This regulated oil then drives the oil servo motor (oil motor) to actuate, ultimately enabling accurate control over the steam flow into the turbine.

As the critical link connecting the regulating signal to the final actuator, the sensitivity, stability, and reliability of the misaligned oil valve pilot spool directly impact the turbine's speed control accuracy, load regulation performance, and operational safety.

II. Product Features

High-Precision Control Performance

- Precision Fit: Utilizes a finely ground spool and sleeve structure, with a fit clearance controlled within the range of 0.005–0.01mm.

- Rapid Response: Ensures fast response to control signals, achieving a regulation sensitivity of 0.01mm-level displacement accuracy, meeting the high-precision speed governing demands of steam turbines.

Excellent Sealing and Anti-Interference Capability

- Multi-Seal Design: Designed with multiple sealing oil chambers and return oil passages to effectively prevent internal control oil leakage and cross-chamber leakage.

- Stability: Minimizes the interference from external oil pressure fluctuations on regulation performance, ensuring control stability under various operating conditions.

High-Strength and Wear-Resistant Structure

- Material: The pilot spool and sleeve are made from high-strength alloy steels (e.g., 20CrNiMo, 12Cr1MoV).

- Hardening: Treated with surface hardening (hardness reaching HRC55–60), providing excellent wear resistance and anti-jamming capability, suitable for long-term, high-frequency regulating actions.

Optimized Oil Flow Design

- Streamlining: Internal oil passages feature a streamlined design to reduce oil flow resistance and vortex losses.

- Efficiency: Minimizes pressure fluctuations during regulation and enhances the utilization efficiency of the control oil.

III. Technical Parameters

| Parameter | Specification / Value |

|---|---|

| Applicable Models | Steam turbine governing systems of various capacity classes (100MW–1000MW) |

| Spool Material Options | 20CrNiMo, 12Cr1MoV, 40CrNiMoA |

| Sleeve Material Options | 20Cr, 1Cr13, 38CrMoAlA (Nitrided treatment) |

| Working Pressure | 1.5–2.5MPa (Control oil pressure) |

| Working Temperature | 30–50℃ (Regulating oil temperature) |

| Stroke Range | 5–30mm (Designed according to regulating demand) |

| Leakage Rate | ≤0.5L/min (Under rated working pressure) |

| Execution Standards | DL/T 794, JB/T 6323, etc. |

IV. Application Scenarios

The steam turbine valve pilot spool is widely used in the governing systems of various steam turbines, including those in thermal power plants, nuclear power stations, and gas-steam combined cycle units. It serves as the core control component for critical valves such as the main steam valve, governing valve, and extraction valve. It is also essential for speed and load regulation during turbine startup, shutdown, and normal operation.

-

Stop Booster Pump Leaks: Master the HZB253-640-01-05 Oil Flinger Install

Stop lube oil leaks. Learn how to control the HZB253-640-01-05 oil flinger gap, why install direction matters, and how to match its life to your bearing overhaul.02-25

-

Why Re-using the HZB253-640-01-03 Locking Washer Risks Total Booster Pump Failure

Don't let bolts come loose. Learn how to check the HZB253-640-01-03 locking washer for fatigue, why you shouldn't re-use it, and how to install it right.02-04

-

Stop Pump Leaks: A Maintenance Guide for the HZB253-640-01-13 Shaft Sleeve

Prevent booster pump shutdowns. Learn how to spot HZB253-640-01-13 shaft sleeve erosion, pitting, and vibration issues before they ruin your mechanical seals.02-02

-

Stability Principles of the HD452D11 Sliding Bearing Under Extreme Dynamic Loads

Master the HD452D11 sliding bearing. Learn how its oil film and anti-vibration design protect feed pump shafts from wear under high-speed power plant loads.01-31

-

FA1D56A-00-1/4 Gasket: Fitting and Shock Protection for Pump Seal Chambers

Stop leaks in your feed pump seal water chamber. Learn how the FA1D56A-00-1/4 gasket matches your pump to resist pressure jumps and cavitation shocks.01-31