Steam Turbine Pump Coupling: The Vital Link in Power Plant Steam Systems

I. Scope of Application: The Vital Link

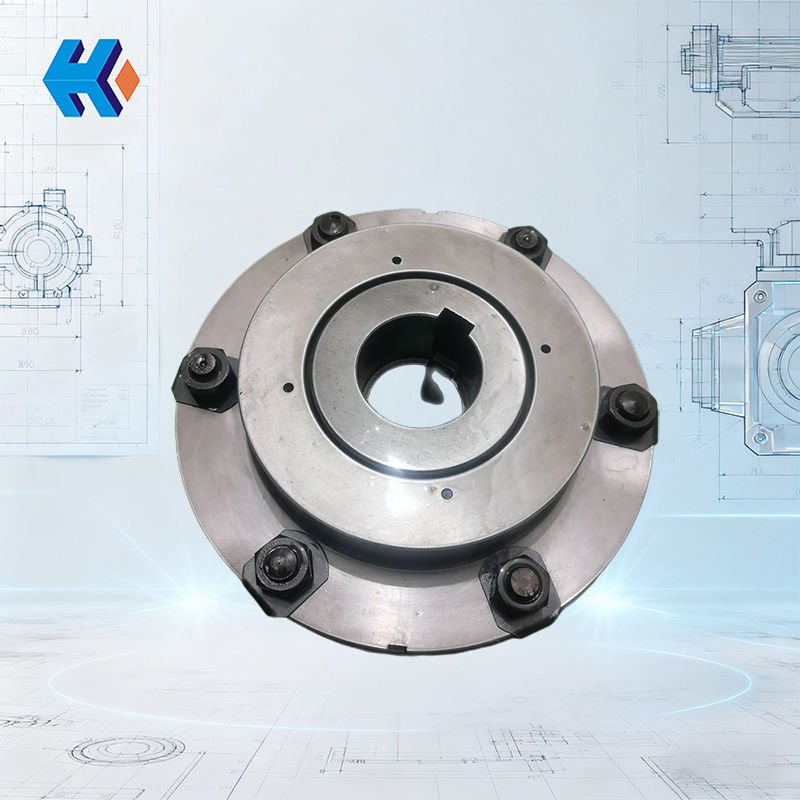

The Steam Turbine Pump - Feed Water Pump Coupling (T-FP Coupling) is a critical transmission component within the power plant steam turbine system, designed to connect the turbine with the boiler feed pump. This coupling does far more than merely transfer power between the turbine and the pump; it is essential for effectively compensating for any inevitable misalignment between the two shafts and dampening operational shocks and vibrations, thus ensuring the overall system runs stably.

The performance of this T-FP coupling directly impacts the efficiency, reliability, and safety of the entire turbine unit, making it an indispensable part of any power generation system.

Is your current coupling a weak link? Upgrade to our precision-engineered T-FP couplings for unmatched stability and long-term performance. Contact us for a quote!

II. Product Features: Built for Demanding Performance

High-Precision Transmission Capability

We utilize advanced manufacturing processes and state-of-the-art precision machining equipment to guarantee that our couplings meet exceptionally high standards for transmission accuracy. The coupling's efficiency ensures that the high-speed power from the steam turbine is transferred to the boiler feed pump with maximum effectiveness and precision, minimizing energy loss and boosting the operational efficiency of the entire integrated system.

The mating components of our couplings feature an extremely precise fit design. This ensures the long-term stability and reliability of the power transmission, preventing equipment malfunctions or operational anomalies that could result from transmission errors over extended periods.

Excellent Compensation Ability

Our T-FP couplings are expertly designed to effectively compensate for misalignment errors that occur between the turbine and feed pump shafts, covering radial offset, axial float, and angular deviation. They are built to adapt to all forms of misalignment that might arise during equipment installation and dynamic operation in a power plant, thereby minimizing the vibration and excessive wear caused by these deviations and ultimately extending the service life of both the turbine and the pump.

Flexible design elements are incorporated into the compensation components, allowing them to deflect freely within a specific range. This provides automatic compensation for shaft misalignment, eliminating the need for frequent and time-consuming adjustments to the equipment installation position, thereby simplifying the often-complex installation and maintenance procedures.

Reliable Damping and Vibration Reduction

The couplings are engineered with highly efficient damping elements specifically designed to effectively absorb shock loads and vibrational energy generated during turbine operation. This significantly reduces the wear and tear caused by vibration on the coupling itself and its adjacent equipment. It noticeably lowers the noise and vibration levels during operation, contributing to a smoother and more comfortable operating environment.

These damping elements are constructed from high-performance elastic materials that offer excellent fatigue resistance and anti-aging properties. This ensures that the cushioning performance remains stable over long operational cycles, guaranteeing reliable equipment operation under a wide variety of load conditions.

High-Strength Materials and Structural Design

The main body of the coupling is manufactured from high-strength alloy steel materials, which undergo rigorous heat treatment. This processing imparts superior mechanical properties and exceptional anti-fatigue performance, allowing the coupling to withstand the extreme high torque and high stress generated during turbine operation. This is key to guaranteeing the coupling's stability and strength throughout its long service life.

The structural design is inherently sound, incorporating optimized connection methods and reinforcing structures that further enhance the overall strength and rigidity of the coupling.

Application Case Studies

Our high-performance Turbine-Feed Pump Couplings have been successfully deployed in numerous large-scale power generation projects, both domestically and internationally. These applications have consistently demonstrated our ability to boost overall equipment performance while dramatically cutting down on maintenance costs and unwanted downtime.

Related Recommended Spares

To complement the Turbine-Feed Pump Coupling and ensure the utmost reliability of your turbo-generator unit, we recommend keeping the following critical spares on hand:

- High-Speed Bolting Sets (Coupling Specific): Precision bolts and nuts designed for high-torque connections.

- Coupling Spacer and Shims: Essential for precise axial adjustment and maintaining correct shaft spacing.

- Flexible Disc Packs (Diaphragm Couplings): For coupling types utilizing these components, crucial for misalignment compensation.

- Specialized Bearing and Oil Seals: For the feed pump and turbine sides, maintaining lubricant integrity and preventing leaks.

Don't wait for a failure. Contact our sales team now to secure a tailored spares package for your turbine system!

HKCYT-2025-10-20

-

Stop Booster Pump Leaks: Master the HZB253-640-01-05 Oil Flinger Install

Stop lube oil leaks. Learn how to control the HZB253-640-01-05 oil flinger gap, why install direction matters, and how to match its life to your bearing overhaul.02-25

-

Why Re-using the HZB253-640-01-03 Locking Washer Risks Total Booster Pump Failure

Don't let bolts come loose. Learn how to check the HZB253-640-01-03 locking washer for fatigue, why you shouldn't re-use it, and how to install it right.02-04

-

Stop Pump Leaks: A Maintenance Guide for the HZB253-640-01-13 Shaft Sleeve

Prevent booster pump shutdowns. Learn how to spot HZB253-640-01-13 shaft sleeve erosion, pitting, and vibration issues before they ruin your mechanical seals.02-02

-

Stability Principles of the HD452D11 Sliding Bearing Under Extreme Dynamic Loads

Master the HD452D11 sliding bearing. Learn how its oil film and anti-vibration design protect feed pump shafts from wear under high-speed power plant loads.01-31

-

FA1D56A-00-1/4 Gasket: Fitting and Shock Protection for Pump Seal Chambers

Stop leaks in your feed pump seal water chamber. Learn how the FA1D56A-00-1/4 gasket matches your pump to resist pressure jumps and cavitation shocks.01-31