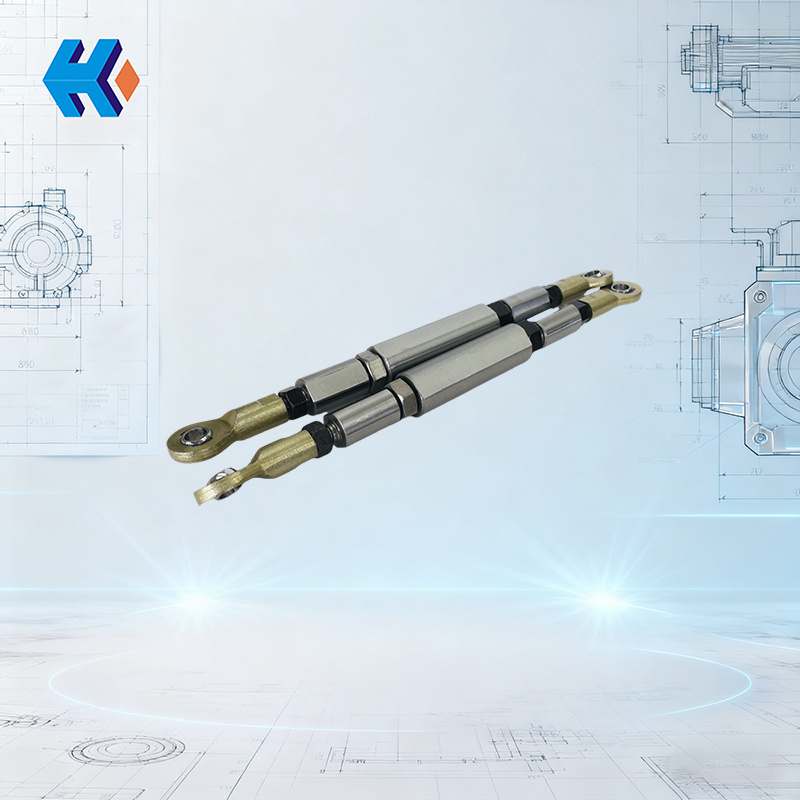

Solving ID Fan Connecting Rod GU23232-12 Fracture: A Highly Efficient Way to End Vibration Exceeding Standard.

Did your 600MW unit's Induced Draft (ID) fan suddenly jump to 200 mm/s or more? That often points right at a snapped ID Fan Connecting Rod, specifically the critical GU23232-12 piece. Hydraulic system spikes—that's the usual killer.

Remember that Datang plant incident? Their rod fractured under massive "squeeze-pull" stress right after a hydraulic pump trip and system repressurization. Vibration went through the roof, way past the safety limit (JB/T9621-1999). The fix? A high-strength replacement: the Dongfang SRI ID Fan Hydraulic Cylinder Connecting Rod GU23232-12.

Here's why the fracture happens, why the vibration explodes, and the real-world solution.

1. Fracture to Catastrophe: How Rod GU23232-12 Failure Starts the Crisis

The GU23232-12 rod is key; it pushes and pulls the movable fan blades. When it breaks, the fan loses all control and goes wildly unbalanced.

| Cause | Breakdown Mechanics | Vibration Effect |

|---|---|---|

| Airflow Chaos | Broken rod means blades flop free. | Rotor is hammered by uneven gas flow every single turn. 1X vibration spikes non-stop. |

| Centrifugal Slam | Hydraulic push-back is gone. Centrifugal force slams the movable blades shut (as per DL/T748.5-2001). | Massive, sudden side-force shock on the rotor. The fan impacts itself. (Think Jingdezhen Power Plant). |

| Fragments & Shocks | Bits of broken GU23232-12 rod spin fast inside. They hit the impeller or the casing. | Collision frequency matches rotor speed, triggering dangerous structural resonance. Vibration gets amplified dangerously high. |

2. The Core Truth: The Fracture Is the Vibration

Engineers must see this as a total system collapse, not just a little broken part. Two major dynamics are immediately wrecked:

- A. Force Control Dies = Balance System Gone: The GU23232-12 rod fights the blade's huge centrifugal force with controlled hydraulic force. Fracture stops this fight instantly. The dynamic balance is smashed, leaving the rotor unprotected against two massive, uncontrolled forces (air and spin).

- B. Secondary Damage Spiral: That initial huge vibration immediately trashes precision parts next door—like the slide block (HU25244-12G) or the blade seals (HU25242-22G). This secondary seizing, oil leak, or blade wobble makes the vibration worse, creating a failure loop that accelerates total breakdown: Break -> High Shake -> More Faults.

3. The Only Solution: High-Strength Rod and the Full Protection Kit

You need a component built to take massive, repeated stress, and a system-level stability plan.

① The High-Strength Replacement: ID Fan Connecting Rod GU23232-12

- Toughness: Forged alloy steel, passed through rigorous hardening (quenching, tempering) and non-destructive testing. It simply resists alternating fatigue stress better.

- Result: The blade opening deviation gets fixed fast. Aerodynamic balance returns. Stability restored.

② Coordinated Protection for GU23232-12 Life

A new rod needs a stable environment. Dongfang SRI recommends these coordinated parts to reinforce the whole hydraulic/blade system:

| Supporting Part (Dongfang SRI) | Job It Does | Vibration Prevention |

|---|---|---|

| Laminated Sealing Ring | Seals the hydraulic cylinder perfectly. | Stops oil leaks. Uneven oil pressure means uneven stress on the GU23232-12. This part protects it. |

| Blade Bolt HU25040-22 + Combined Seal | Keeps the fan blade (HU25238-22) locked down. | Eliminates any blade looseness. This prevents extra, unplanned load from stressing the new GU23232-12 rod. |

| Axial ID Fan HU25038-22 | The complete assembly (for 600MW fans). | Recommended when the whole fan is old. Ensures the new GU23232-12 works inside a modern, fully compatible system. |

For a tough, high-tensile replacement that meets the highest power plant standards, the Dongfang SRI ID Fan Hydraulic Cylinder Connecting Rod GU23232-12 is your definite answer to stable, compliant fan operation.

-

Stop Booster Pump Leaks: Master the HZB253-640-01-05 Oil Flinger Install

Stop lube oil leaks. Learn how to control the HZB253-640-01-05 oil flinger gap, why install direction matters, and how to match its life to your bearing overhaul.02-25

-

Why Re-using the HZB253-640-01-03 Locking Washer Risks Total Booster Pump Failure

Don't let bolts come loose. Learn how to check the HZB253-640-01-03 locking washer for fatigue, why you shouldn't re-use it, and how to install it right.02-04

-

Stop Pump Leaks: A Maintenance Guide for the HZB253-640-01-13 Shaft Sleeve

Prevent booster pump shutdowns. Learn how to spot HZB253-640-01-13 shaft sleeve erosion, pitting, and vibration issues before they ruin your mechanical seals.02-02

-

Stability Principles of the HD452D11 Sliding Bearing Under Extreme Dynamic Loads

Master the HD452D11 sliding bearing. Learn how its oil film and anti-vibration design protect feed pump shafts from wear under high-speed power plant loads.01-31

-

FA1D56A-00-1/4 Gasket: Fitting and Shock Protection for Pump Seal Chambers

Stop leaks in your feed pump seal water chamber. Learn how the FA1D56A-00-1/4 gasket matches your pump to resist pressure jumps and cavitation shocks.01-31