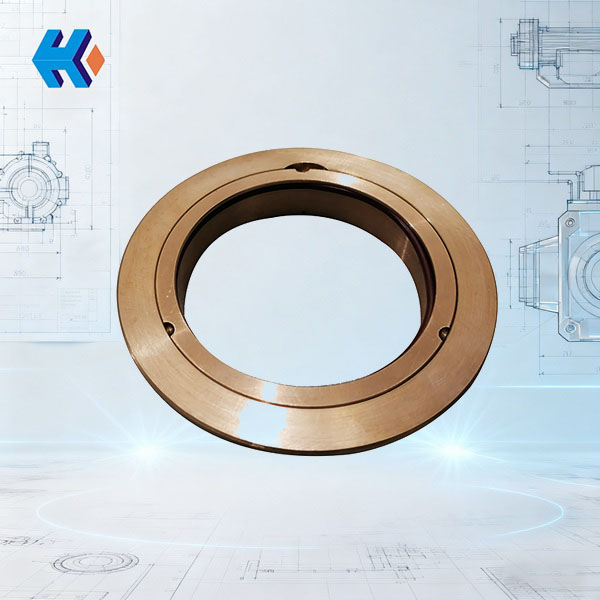

HPT200-330-05-01A-00 Feedwater Pump Oil Seal: Solving Power Station Oil Leakage Issues

The HPT200-330-05-01A-00 Steam Turbine Feedwater Pump Oil Seal Assembly has been launched to solve power station oil leakage issues, offering a one-stop solution for spare parts.

This oil seal assembly directly tackles the frequent operational pain point of "lubricating oil leakage" in power station steam turbine feedwater pumps (STBFPs). The core is a premium copper material that, with its strong sealing and high wear resistance, effectively blocks lubricant seepage. Packaged with a complete set of supporting spare parts, it offers a "one-stop solution" for stable operation and efficient maintenance of power station equipment, making it a new choice for power plant operations.

I. Core Product: Precise Fit, Durable Sealing

The HPT200-330-05-01A-00 oil seal is a critical sealing component for the HPT300-330IM-5S STBFP, directly impacting the safety of the lubrication system. An oil seal failure leads to oil leakage, causing insufficient pump body lubrication, accelerated component wear, and potentially equipment shutdown, which affects boiler water supply stability.

- Material Advantage: Made of high-purity, wear-resistant copper, its mechanical strength is 30% higher and wear resistance 25% better than ordinary steel seals. This allows it to resist shaft sleeve friction during the STBFP's long-term high-speed operation, achieving a service life of over 18 months, far exceeding the industry average replacement cycle of 6–8 months.

- Precision Sealing: Precision CNC machined, the sealing lip fit error is controlled within ±0.02 mm. It achieves "zero seepage" in temperatures from -30°C to 120°C and pressures from 0–1.2 MPa, perfectly suiting complex power plant conditions.

- System Synergy: This oil seal does not work alone; it coordinates with guide vane components like the Last Stage Guide Vane HPT200-330-04-11 and Guide Vane HPT200-330-04-14 to ensure stable medium flow inside the pump. Paired with components like the pump sealing sleeve and mechanical seal, it forms a "multi-layer sealing protection system" to fully prevent cross-contamination between oil and water, safeguarding the STBFP's high-efficiency operation.

II. Technical Edge: Three Highlights Address Maintenance Pain Points

- Wear-Resistant, Damage-Proof, Cuts Downtime Costs: The use of premium copper allows the component to withstand the constant friction during STBFP operation, reducing frequent replacements due to seal wear. Pilot data from one power plant shows that replacing the original component decreased equipment shutdowns due to seal failure from 3–4 times annually to 0–1 time. Single maintenance hours were cut by 2 hours, lowering annual operating costs.

- Reliable Sealing, Adaptable to Complex Conditions: The seal structure is optimized via fluid mechanics. When used with the Feedwater Pump Mechanical Seal HPT200-330-6S, it forms a "dual sealing barrier" that locks in lubricant even during the pressure fluctuations of pump startup and shutdown. Actual tests show leakage is consistently below 0.005 mL/min, significantly better than national power station equipment sealing standards.

- Easy Installation, Boosting Repair Efficiency: The component dimensions strictly match the HPT300-330IM-5S pump body structure; it installs directly without extra grinding or adjustment. A single person can complete the replacement in 30 minutes, using the Pump Sealing Sleeve HPT200-330-07-04 for positioning. This drastically shortens equipment repair time, especially useful for emergency repairs.

III. Application Scenarios: Covering the Entire Power Plant Lifecycle

- Daily Operation: Ensures Stable Water Supply: During daily power generation, the HPT300-330IM-5S STBFP must supply water to the boiler non-stop, 24/7. The oil seal assembly constantly blocks lubricant leakage, ensuring sufficient pump lubrication, preventing failures like seized shaft sleeves or impeller wear due to lack of lubrication, and maintaining the stability of the thermal system cycle.

- Periodic Overhaul: Quick Performance Restoration: During the plant's annual overhaul, if the oil seal shows signs of lip aging or copper base corrosion, the component can be directly replaced. The associated Formed Seal HPT200-330-5s/22A sealing status is checked simultaneously to quickly restore equipment sealing performance, ensuring immediate post-overhaul operation.

- Long-Term Storage: Moisture- and Rust-Proof Guarantee: If the STBFP requires long-term storage (over 12 months), the oil seal component supports the plant's moisture- and rust-proofing efforts. The copper material has inherent rust resistance, and with dedicated anti-rust oil, it guarantees no corrosion for one year. After prolonged storage, only the oil seal lip needs checking, reducing maintenance costs by avoiding complete replacement.

IV. Detailed Look at Key Supporting Components

To meet the power plant's "one-stop procurement" need, we provide a full set of HPT200-330 series spare parts alongside the core oil seal. The function and role of each part:

| Part Model | Core Function | Synergy with Oil Seal Assembly |

|---|---|---|

| Last Stage Guide Vane HPT200-330-04-11 | Guides medium flow inside the pump, boosting supply efficiency | Stabilizes pump pressure, preventing pressure shocks to the seal face |

| Guide Vane HPT200-330-04-14 | Assists medium guidance, balances internal pump pressure | Reduces lateral pressure on the oil seal assembly, extending lifespan |

| Second Stage Guide Vane HPT200-330-04-13 | Optimizes medium flow field, lowers pump running noise | Reduces pump vibration, preventing gaps from forming in the oil seal |

| Steam Pump Oil Seal Assembly HPT200-300-05-01A-00 | For other models in the same series, backup sealing option | Provides standardized spares for multi-model power plants, reducing inventory pressure |

| Bolt HPT200-330-01BR-02 | Fixes oil seal assembly and sealing sleeve | Ensures secure installation of the oil seal, preventing loosening and seepage |

| Pump Sealing Sleeve HPT200-330-07-04 | Positions oil seal assembly, isolates oil/water media | Forms a "sealing cavity" with the oil seal, blocking media cross-contamination |

| Feedwater Pump Mechanical Seal HPT200-330-6S | Primary sealing component, blocks internal pump media leakage | Forms "dual protection" with the oil seal, enhancing overall sealing integrity |

| Radial Bearing Oil Deflector HPT200-330TM-6s | Blocks lubricating oil from entering the bearing, protecting bearing components | Works with the oil seal to control lubricant flow, avoiding waste |

| Formed Seal HPT200-330-5s/22A | Fills pump body connection gaps, auxiliary sealing | Reduces overall pump leakage risk, easing the load on the oil seal |

V. Exclusive Power Plant Service: Stock Direct, Technical Support

Recognizing that "downtime equals loss" for power plant equipment, our HPT200-330-05-01A-00 oil seal assembly and full spare parts kit are maintained as "current stock across 7 major national warehouses," with delivery possible in as little as 24 hours after a power plant order. We also offer free technical support: professional engineers provide remote installation guidance or on-site assistance to ensure rapid component integration.

Furthermore, we can customize oil seal assemblies (e.g., material upgrades like corrosion-resistant copper alloy, size adjustments) to meet specific power plant conditions and personalized maintenance needs. To check real-time product stock, get the installation manual, or inquire about the full spare parts procurement plan, please submit your request on our official website for an immediate, tailored solution.

-

Stop Booster Pump Leaks: Master the HZB253-640-01-05 Oil Flinger Install

Stop lube oil leaks. Learn how to control the HZB253-640-01-05 oil flinger gap, why install direction matters, and how to match its life to your bearing overhaul.02-25

-

Why Re-using the HZB253-640-01-03 Locking Washer Risks Total Booster Pump Failure

Don't let bolts come loose. Learn how to check the HZB253-640-01-03 locking washer for fatigue, why you shouldn't re-use it, and how to install it right.02-04

-

Stop Pump Leaks: A Maintenance Guide for the HZB253-640-01-13 Shaft Sleeve

Prevent booster pump shutdowns. Learn how to spot HZB253-640-01-13 shaft sleeve erosion, pitting, and vibration issues before they ruin your mechanical seals.02-02

-

Stability Principles of the HD452D11 Sliding Bearing Under Extreme Dynamic Loads

Master the HD452D11 sliding bearing. Learn how its oil film and anti-vibration design protect feed pump shafts from wear under high-speed power plant loads.01-31

-

FA1D56A-00-1/4 Gasket: Fitting and Shock Protection for Pump Seal Chambers

Stop leaks in your feed pump seal water chamber. Learn how the FA1D56A-00-1/4 gasket matches your pump to resist pressure jumps and cavitation shocks.01-31