Critical ID Fan Maintenance: Why Sealing the Outlet Damper is Non-Negotiable When Replacing Actuator Link Rods DTYD100UI002

Critical ID Fan Maintenance: Why Sealing the Outlet Damper is Non-Negotiable When Replacing Actuator Link Rods DTYD100UI002

The Hidden Risk: Overlooking ID Fan Outlet Damper Sealing

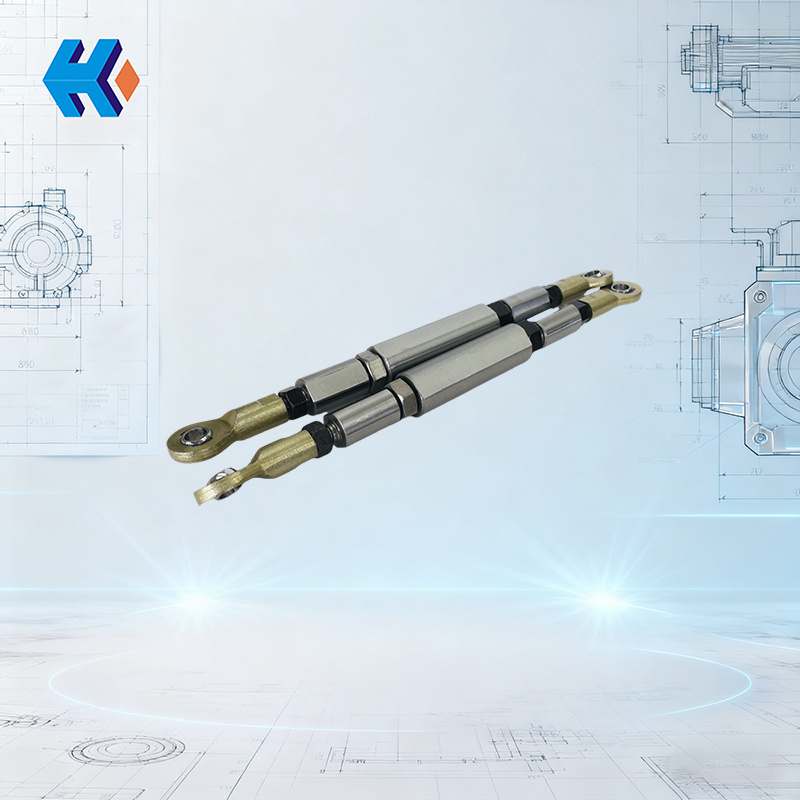

When performing maintenance on a broken fan actuator link rod assembly, the most common pitfall is the failure to properly seal the Induced Draft (ID) Fan outlet damper. As mandated by the "Maintenance Safety Protection" requirements in the DL/T 468-2019 Guideline for Selection and Use of Fans in Power Station Boilers, this step is directly related to the safety of the work area around the fractured link rod. It is especially crucial when replacing the specific Actuator Link Rod DTYD100UI002, as it fundamentally mitigates multiple risks.

The Core Problem: When the ID fan is shut down, if the outlet damper is not sealed, residual high-temperature flue gas (150–200°C) from the boiler side will backflow into the fan interior through the duct. The fractured area of the link rod assembly (e.g., the fracture cross-section, the connection point to the hydraulic cylinder) is the core maintenance zone. Exposure to backflowing flue gas not only compromises personnel safety but also affects the installation precision of the new DTYD100UI002 link rod—a major reason why many operators still experience transmission deviations after replacement.

Four Guarantees Provided by Proper Damper Sealing

1. Temperature Isolation: Protecting Personnel and Components

The high temperature of the backflowing flue gas causes the metal at the link rod fracture to undergo thermal expansion and contraction. This leads to measurement errors in the fracture dimensions (e.g)

2. Corrosion Prevention: Ensuring Link Rod Installation Accuracy

Sulfur dioxide and nitrogen oxides in the flue gas can corrode the metal cross-section of the link rod fracture, forming a rust layer. Without proper sealing, these corrosive impurities adhere to the fractured area. Sealing prevents corrosive gas ingress, keeping the fractured area and the new link rod surface clean, ensuring smooth transmission after the DTYD100UI002 is fitted.

3. Pressure Stabilization: Preventing Component Collision

An unsealed outlet damper connects the fan interior with the boiler flue gas duct. When an adjacent boiler adjusts its load, the fan interior can experience negative or positive pressure surges. This pressure fluctuation may cause the fractured link rod end to shift, potentially colliding with the impeller (HU25040-22G-08), and can also cause misalignment when disassembling or assembling the blade bolts (DYL2420-50).

By reinforcing the seal with the CPMW Seal Ring TY9117C UZ22000 (DY) Series T17. This stabilizes the position of the fractured link rod end, allowing for precise operation when removing the old rod or installing the new DTYD100UI002 link rod, thereby preventing bolt installation deviations.

4. Debris Isolation: Extending Complementary Component Life

Backflowing flue gas carries fly ash and coal dust. If these particulates adhere to the clevis pin bearing (e.g., Bearing DJJQ40 W5 U236D00 (DY)) or the scraper ring (I UZ22000 (DY)) near the fractured link rod end, it can cause the bearing to seize. When the new DTYD100UI002 link rod is installed, a seized bearing increases transmission resistance, shortening the lifespan of both the link rod and the bearing. Sealing followed by cleaning the fan interior prevents this issue, ensuring the transmission resistance of the DTYD100UI002 link rod remains within the standard range and extending the durability of complementary parts like the scraper ring and bearings.

Practical Tip for Sealing Implementation

Action Key: When sealing, first secure the outlet damper. Use a chain hoist to firmly fix the damper door, then apply the CPMW Laminated Seal U184011 UZ22000 (DY) Series T10 along the edge, followed by reinforcement with a #10 round steel bar. This method is significantly more secure than relying solely on asbestos rope and prevents the seal from falling off during maintenance.

Before replacing the DTYD100UI002 link rod, always confirm the sealing integrity. Then, proceed to align the new link rod with the 01 Model Coupling 5001.1 U238\2ZT (DY) connection, ensuring compliance with the DL/T 468-2019 requirement of “adjustment mechanism transmission accuracy 1%”. This is essential for long-term, trouble-free fan operation.

In summary: Sealing the ID fan outlet damper is not an optional step; it is the safety baseline for link rod fracture maintenance. Choosing a wear-resistant and highly adaptable link rod like the DTYD100UI002, paired with quality components like CPMW seals and blade bolts, allows you to meet safety standards while ensuring the long-term stability of the ID fan's adjustment system—the right path for efficient and worry-free power plant maintenance.

HKZX-2025-10-24

-

Stop Booster Pump Leaks: Master the HZB253-640-01-05 Oil Flinger Install

Stop lube oil leaks. Learn how to control the HZB253-640-01-05 oil flinger gap, why install direction matters, and how to match its life to your bearing overhaul.02-25

-

Why Re-using the HZB253-640-01-03 Locking Washer Risks Total Booster Pump Failure

Don't let bolts come loose. Learn how to check the HZB253-640-01-03 locking washer for fatigue, why you shouldn't re-use it, and how to install it right.02-04

-

Stop Pump Leaks: A Maintenance Guide for the HZB253-640-01-13 Shaft Sleeve

Prevent booster pump shutdowns. Learn how to spot HZB253-640-01-13 shaft sleeve erosion, pitting, and vibration issues before they ruin your mechanical seals.02-02

-

Stability Principles of the HD452D11 Sliding Bearing Under Extreme Dynamic Loads

Master the HD452D11 sliding bearing. Learn how its oil film and anti-vibration design protect feed pump shafts from wear under high-speed power plant loads.01-31

-

FA1D56A-00-1/4 Gasket: Fitting and Shock Protection for Pump Seal Chambers

Stop leaks in your feed pump seal water chamber. Learn how the FA1D56A-00-1/4 gasket matches your pump to resist pressure jumps and cavitation shocks.01-31