Enhanced Durability and Efficiency: HU25042-221G Induced Draft Fan Blades for High Back Pressure Flue Gas Systems

Enhanced Durability and Efficiency: HU25042-221G Induced Draft Fan Blades for High Back Pressure Flue Gas Systems

The Challenge: Managing High Back Pressure without Booster Fans

In the current trend of energy conservation and consumption reduction in thermal power units, an increasing number of power plants are opting to eliminate the sulfur dioxide removal (FGD) system booster fan. This transfers the entire flue gas system pressure drop burden onto the Induced Draft (ID) fan. While this design simplifies the system and lowers initial investment costs, it places extremely high demands on the ID fan, particularly its variable pitch control system.

Taking a 330MW unit at a State Power combined heat and power company as an example, its FGD system uses a limestone-gypsum wet process without a booster fan. The ID fan must overcome an additional resistance of approximately 800 to 1200 Pa from the absorber tower, demister, and ductwork.

This demanding condition requires the ID fan to not only maintain sufficient pressure at high loads but also precisely regulate airflow at medium and low loads, avoiding frequent and large-scale adjustments of the variable pitch blades. Prolonged operation under these conditions significantly increases the alternating stress on the blades, compresses the adjustment range, and often leads to reduced efficiency, excessive vibration, and even fatigue cracking of the blades.

Safety and Compliance Concerns

According to the JB/T 8689-2014 Standard for Vibration Limits of Ventilators, if the blade strength or aerodynamic design is insufficient under such operating conditions, it is highly likely to exceed the Class C limit, threatening equipment safety. Furthermore, frequent adjustments impose severe strains on blade seals, bearings, and the actuating mechanism.

The Solution: HU25042-221G High-Performance ID Fan Blades

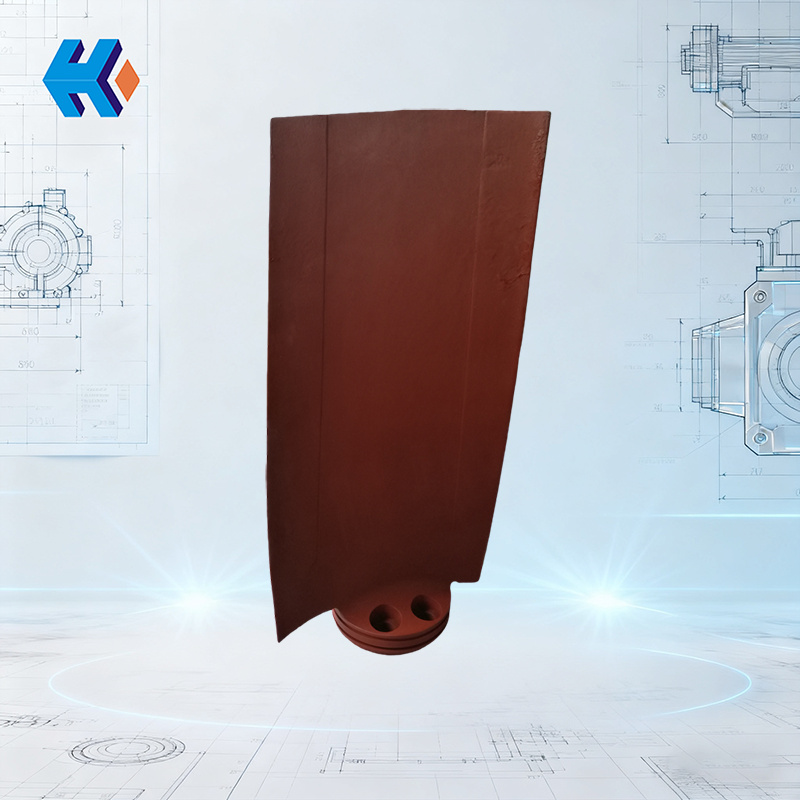

The HU25042-221G ID fan blade (Model: U2616G2106Y00) is specifically engineered for high back pressure and wide adjustment range operation.

- Superior Material & Surface Treatment: The blade utilizes high-strength Q345D steel coupled with a surface strengthening treatment. It is sandblasted and derusted according to the GB/T 8923.1-2011 standard, resulting in strong coating adhesion and excellent corrosion resistance.

- Optimized Aerodynamic Design: The blade’s aerodynamic profile has been optimized through CFD (Computational Fluid Dynamics) analysis. It maintains a wide high-efficiency zone and large stall margin across an adjustment range of -36° to +20°, effectively managing pressure drop fluctuations from the FGD system.

Comprehensive Supporting Components for System Reliability

We provide a complete set of supporting components to ensure reliable system synergy:

|

Component Category |

Part Number(s) |

Key Feature |

|

Sealing |

O-ring Seal (HU25240-22) & Hub O-ring Seal (DTSD60LG016) |

Dual sealing mechanism to prevent flue gas leakage. |

|

Bearing & Shaft |

Sliding Bearing (DTYD100UZ024) & Main Shaft (DTYD30UZ001) |

High-load alloy bearing with precision-machined main shaft for minimized vibration. |

|

Fasteners |

ID Fan Blade Bolt (DYL2420-75) & Blade Bolt (DTYD100UG005) |

Ultrasonic testing per GB/T 11345-2013 to eliminate internal defects. |

|

Actuation |

Actuator Link Rod (DTYD30UI001) |

Enhanced rigidity for more precise and responsive control. |

|

Duct Connection |

Expansion Joint Rubber Sheet (6500×180×8) |

Temperature and corrosion-resistant, absorbs thermal displacement, protects the fan body. |

Proven Performance and Economic Benefits

Practical application in similar power plant retrofit projects confirms the advantages of the HU25042-221G blade:

- The ID fan maintains ample adjustment margin even at the high load of 275MW.

- Efficiency increased by over 6%.

- Annual power savings exceeding 2.4 million kWh.

Conclusion: Eliminating the FGD booster fan poses a "stress test" for the ID fan's variable pitch system. Choosing the HU25042-221G high-performance blade and its complete component set is a fundamentally sound decision to enhance system reliability and economic efficiency.

HKZX-2025-10-24

-

Stop Booster Pump Leaks: Master the HZB253-640-01-05 Oil Flinger Install

Stop lube oil leaks. Learn how to control the HZB253-640-01-05 oil flinger gap, why install direction matters, and how to match its life to your bearing overhaul.02-25

-

Why Re-using the HZB253-640-01-03 Locking Washer Risks Total Booster Pump Failure

Don't let bolts come loose. Learn how to check the HZB253-640-01-03 locking washer for fatigue, why you shouldn't re-use it, and how to install it right.02-04

-

Stop Pump Leaks: A Maintenance Guide for the HZB253-640-01-13 Shaft Sleeve

Prevent booster pump shutdowns. Learn how to spot HZB253-640-01-13 shaft sleeve erosion, pitting, and vibration issues before they ruin your mechanical seals.02-02

-

Stability Principles of the HD452D11 Sliding Bearing Under Extreme Dynamic Loads

Master the HD452D11 sliding bearing. Learn how its oil film and anti-vibration design protect feed pump shafts from wear under high-speed power plant loads.01-31

-

FA1D56A-00-1/4 Gasket: Fitting and Shock Protection for Pump Seal Chambers

Stop leaks in your feed pump seal water chamber. Learn how the FA1D56A-00-1/4 gasket matches your pump to resist pressure jumps and cavitation shocks.01-31