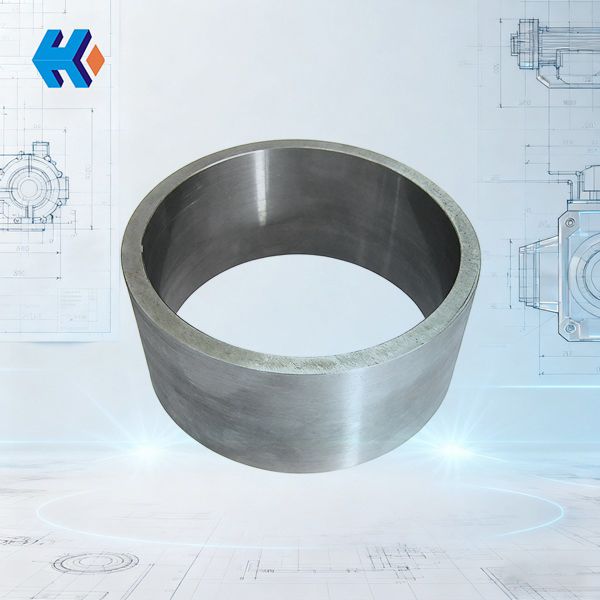

Shaft Sleeve FA1D56-01-07 Praised by Power Plant Technicians: The "Invisible Bodyguard" for Booster Pump Seals

Power plant O&M personnel know well that a leak in the boiler feed pump booster pump can cause massive trouble—minor leaks lead to shutdown and lost generation, while severe leaks mean replacing numerous costly components. However, one specific part is constantly praised by technicians for its reliability: the FA1D56-01-07 Mechanical Seal Shaft Sleeve, custom-designed for the FA1D56 model booster pump. Though just a small component fitted onto the shaft, the entire pump's sealing system is prone to failure without its support.

Specialized suppliers like Dongfang SRI, who deeply focus on power plant spare parts, offer this shaft sleeve as a core product. They strictly benchmark their material selection and production processes against original manufacturer standards, giving power plants confidence in its reliability.

Not a Solo Act! The Shaft Sleeve Must Be Paired with These Components

The FA1D56-01-07 shaft sleeve is never a "lone wolf"; it must cooperate with a bundle of accessories to function effectively. A missing piece can lead to problems.

Core Partners: Ensuring Shaft Stability and Oil Containment

- Thrust Pad FA1D56A: This component stabilizes the pump shaft. Without its cooperation, the shaft would wobble during rotation, causing the shaft sleeve and seal face to oscillate, making media leakage inevitable.

- Oil Seal Assembly FA1D56-03-03: Responsible for retaining the lubricating oil. If the two do not coordinate well, the lubricating oil leaks out and mixes with the pump's working medium, contaminating the medium and accelerating shaft sleeve wear.

The "Supporting Cast" That Is Crucial to Check

When replacing the shaft sleeve, technicians typically check the Oil Seal Sleeves—such as FA1D56-01-15 and FA1D56-01-06—as well as the Oil Deflector Ring FA1D56-A2-102761.

Real Incident: One power plant once tried to save effort by replacing only the shaft sleeve without checking the oil seal sleeve. Two months later, the leak recurred. Upon disassembly, the old oil seal sleeve was found to have grooves worn into it—a wasted effort. These "supporting cast" components together form the complete sealing and protection circle.

Three Key Advantages Make This Shaft Sleeve "Durable and Easy to Install"

Why are power plant technicians willing to spend a bit more for the FA1D56-01-07? Ultimately, its practical advantages solve real-world problems, and Dongfang SRI has optimized these advantages to the extreme.

Smooth Surface Guarantees Reliable Sealing

Ordinary shaft sleeves often have a rough finish, preventing a tight fit with the mechanical seal's rotating ring, leading to leaks soon after installation. However, the shaft sleeve manufactured by Dongfang SRI undergoes meticulous surface treatment—it is exceptionally smooth, allowing it to fit tightly and seamlessly against the rotating seal ring, greatly reducing the probability of media leakage through the gap.

Even the areas that contact the auxiliary seal ring are finely finished, minimizing friction during rotation, reducing wear on the seal ring, and cutting down on the need for frequent replacements.

Technician Feedback: Using Dongfang SRI's shaft sleeve can nearly double the life of the seal ring.

Durable Material Ensures Long Service Life

It uses 1Cr17Ni2 material, which, in simple terms, means it is "tough." The medium inside the boiler feed pump booster pump can sometimes be corrosive. While ordinary steel may rust and deform over time, this shaft sleeve is immune.

Case Example: An older power plant using an FA1D56 pump previously had to replace the standard shaft sleeve every six months. After switching to the Dongfang SRI FA1D56-01-07, the pump operated for a full 18 months before requiring an overhaul. Technicians agree this saved significant maintenance effort. Furthermore, they can obtain a material inspection report from Dongfang SRI, eliminating the need for extra effort on independent material testing.

Strong Compatibility, No Extra Adjustments Required

Power plant overhauls are already busy, and no one wants to spend time filing down a spare part. The Dongfang SRI shaft sleeve is highly compatible with the bearing housing—it installs without extra adjustment, whether the bearing housing model is FA1D56A-05 or FA1D56A-02. It also perfectly matches components like the feedwater pump booster pump's Bearing Housing FA1D56-01 and End Cap FA1D56-02.

This Shaft Sleeve is Indispensable in These Scenarios

The FA1D56-01-07 shaft sleeve has a high "appearance rate" in power plants. It is relevant to almost any maintenance involving the FA1D56 boiler feed pump booster pump, and Dongfang SRI offers complementary services for various scenarios.

Routine Maintenance: Check the Shaft Sleeve First for Leaks

During routine inspection, if technicians notice a slight medium leak from the pump body, their first reaction is to "check if the shaft sleeve is worn." Upon disassembly, if the shaft sleeve surface has scratches or wear, replacing it with a Dongfang SRI FA1D56-01-07 and simultaneously replacing their Gasket FA1D56-03-09 usually solves the problem without major intervention.

Major Overhaul: Mandatory Replacement When Changing Bearing Housing

During a major unit overhaul, this shaft sleeve is essential. As long as components like the bearing housing or end cap are being replaced, technicians always swap out the old shaft sleeve—otherwise, pairing a new bearing housing with an old shaft sleeve can cause a seal face mismatch and subsequent leaks, trading short-term savings for long-term trouble.

Emergency Repair: Stocking Spares Saves the Day

Some meticulous power plants keep this shaft sleeve in stock to handle sudden nighttime leaks.

Emergency Case: One plant experienced a midnight shutdown due to a leak in the booster pump. Because they had stocked spares from Dongfang SRI, an emergency team was coordinated from a nearby warehouse immediately after a call. The pump was repaired and back online within two hours, preventing major generation loss. Waiting for other manufacturers to ship could have caused a delay of at least a week.

No Need to Worry About Choosing a Spare Part—Find the Right Supplier to Avoid Trouble

In reality, reliable power plant parts don't need to be overly complicated. Technicians value components like the FA1D56-01-07—durable, highly compatible, and effective at solving practical problems. Finding a reliable supplier like Dongfang SRI makes maintenance much easier.

| Part Number | Item Description |

| HZB253-640-02-01 | Feedwater Pump Non-Drive End O-Ring |

| HTHP-01-02-19-01 | Horizontal Split Surface Bolt |

| FA1D67-02-01 | Oil Deflector Ring |

| FA1D63-02-07A | Oil Retaining Ring |

| FT6U41M-03-02 | First Stage Impeller |

| HPT300-340-MF-01-03 | Water Deflector Ring |

| DG600-240V | Seal Retaining Ring (or Seal Backing Ring) |

| FT9Q36M-04-01 | Guide Vane |

| HZB235-640-03-09 | Steam Pump Booster Pump Heat-Resistant Rubber O-Ring |

| HZB253-640-03-09 | Booster Pump O-Ring |

Dongfang SRI not only has sufficient stock of the FA1D56-01-07 shaft sleeve but can also compile "one-stop overhaul packages" that include complementary parts like thrust pads, oil seal assemblies, and gaskets, based on the power plant's needs. All parts undergo original-fit testing, so there's no fear of "not fitting" or "short lifespan." Furthermore, their engineers provide free remote technical guidance, available for consultation on everything from installation clearance adjustment to diagnostic standards for routine maintenance.

If your power plant also uses the FA1D56 model booster pump and you want to reliably select the FA1D56-01-07 shaft sleeve with peace of mind, or if you need complementary overhaul spare parts, contact Dongfang SRI. They can streamline your power plant's operation and maintenance, ensuring equipment stability.

HKCYT-2025-10-28

-

Stop Booster Pump Leaks: Master the HZB253-640-01-05 Oil Flinger Install

Stop lube oil leaks. Learn how to control the HZB253-640-01-05 oil flinger gap, why install direction matters, and how to match its life to your bearing overhaul.02-25

-

Why Re-using the HZB253-640-01-03 Locking Washer Risks Total Booster Pump Failure

Don't let bolts come loose. Learn how to check the HZB253-640-01-03 locking washer for fatigue, why you shouldn't re-use it, and how to install it right.02-04

-

Stop Pump Leaks: A Maintenance Guide for the HZB253-640-01-13 Shaft Sleeve

Prevent booster pump shutdowns. Learn how to spot HZB253-640-01-13 shaft sleeve erosion, pitting, and vibration issues before they ruin your mechanical seals.02-02

-

Stability Principles of the HD452D11 Sliding Bearing Under Extreme Dynamic Loads

Master the HD452D11 sliding bearing. Learn how its oil film and anti-vibration design protect feed pump shafts from wear under high-speed power plant loads.01-31

-

FA1D56A-00-1/4 Gasket: Fitting and Shock Protection for Pump Seal Chambers

Stop leaks in your feed pump seal water chamber. Learn how the FA1D56A-00-1/4 gasket matches your pump to resist pressure jumps and cavitation shocks.01-31