20MG30.11.13.99 Medium speed coal mill Upper Tie Rod

20MG30.11.13.99 Medium speed coal mill Upper Tie Rod

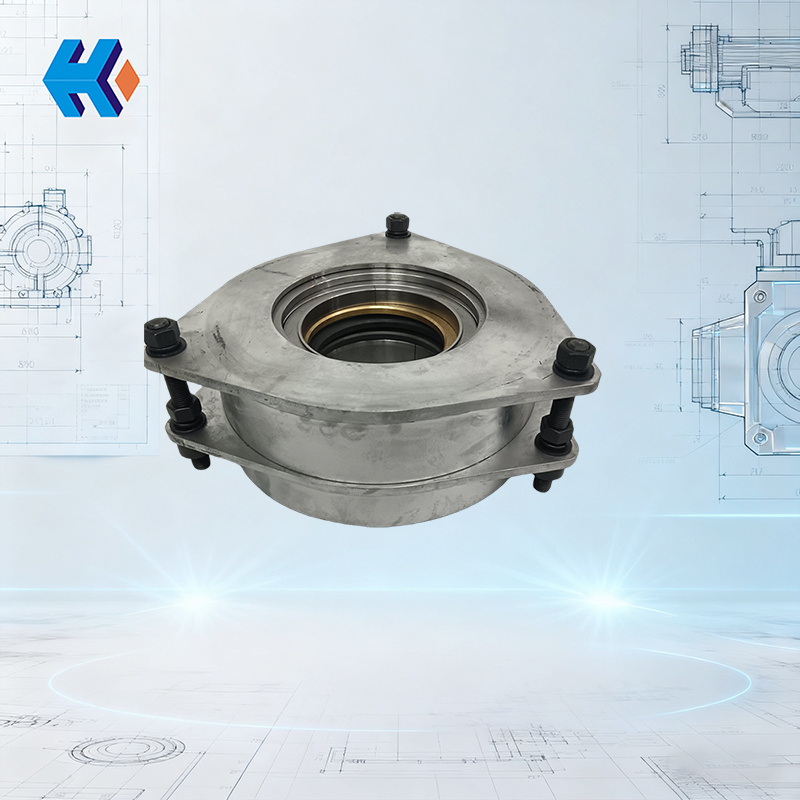

The Upper Tie Rod 20MG30.11.13.99 is a vital support component within the coal mill, primarily used to connect and fix the mill's upper structure, ensuring the stability of the coal mill during operation. Its design fully accounts for the complex working conditions of the coal mill, including high temperatures, high pressure, and abrasive environments. Manufactured from high-quality materials and precisely machined, it possesses excellent mechanical properties and durability.

Component Overview

The Upper Tie Rod 20MG30.11.13.99 is a support assembly specifically designed for coal mills, with specifications that meet the operational demands of the equipment. As a critical internal support component, the tie rod provides reliable support to the mill's upper structure through its high strength and stability, ensuring the equipment does not experience displacement or excessive vibration due to uneven stress during operation.

Key Technical Features

-

Support Function: With its high-strength structural design, the upper tie rod is capable of bearing the weight of the mill's upper structure. It provides stable support for the mill's core components, ensuring the equipment runs without shifting or vibrating due to unbalanced forces.

-

Stability Assurance: Through optimized design, the tie rod effectively distributes the pressure generated during mill operation, reducing equipment failures caused by wear or vibration and extending the overall service life of the machine.

-

High Temperature and Pressure Resistance: Constructed from premium materials and featuring a multi-layer wear-resistant structure, the tie rod's strength and durability are significantly enhanced, enabling it to withstand the complex conditions of high temperature, high pressure, and abrasion inside the mill.

-

Modular Design: The modular nature of the upper tie rod facilitates easier maintenance and replacement, thereby lowering equipment maintenance costs and boosting the operational efficiency of the coal mill.

We can provide the following coal mill accessories:

|

Carbon Graphite Sealing Ring |

300MG53.11.06.97 |

|

Scraper Device / Scraper Unit |

300MG53.11.07.01 |

|

Check Valve / Non-Return Valve |

ZNGF02010301 |

|

Filter Element |

DFDK BN/HC 60 |

|

Upper Tie Rod / Upper Pull Rod |

20MG40.11.13.99 |

|

Sealing Air Duct |

20MG40.11.23T |

|

Rolling Reversing Valve Sealing Assembly / Set |

ZGM113-II |

|

Shaft Sleeve / Bushing |

20MG43.11.09.35 |

|

Breather / Air Filter |

20MG43.0011.09.01 |

|

Oil Seal Support Bracket / Oil Seal Holder |

20MG43.11.09.37 |

|

Shaft Sleeve / Bushing |

20MG40.11.09.84T |

|

Dowel Pin / Pivot Pin |

21MG30.11.02 |

|

Dowel Pin / Pivot Pin |

MG20.11.02 |

|

Rolling Reversing Valve |

MG00.11.19.01 |

|

Guide Block |

20MG40.11.12.07.96 |

|

Protective Cover / Guard |

20MG42.11.09.3 |

HKZX-2025-11-05

-

Stop Booster Pump Leaks: Master the HZB253-640-01-05 Oil Flinger Install

Stop lube oil leaks. Learn how to control the HZB253-640-01-05 oil flinger gap, why install direction matters, and how to match its life to your bearing overhaul.02-25

-

Why Re-using the HZB253-640-01-03 Locking Washer Risks Total Booster Pump Failure

Don't let bolts come loose. Learn how to check the HZB253-640-01-03 locking washer for fatigue, why you shouldn't re-use it, and how to install it right.02-04

-

Stop Pump Leaks: A Maintenance Guide for the HZB253-640-01-13 Shaft Sleeve

Prevent booster pump shutdowns. Learn how to spot HZB253-640-01-13 shaft sleeve erosion, pitting, and vibration issues before they ruin your mechanical seals.02-02

-

Stability Principles of the HD452D11 Sliding Bearing Under Extreme Dynamic Loads

Master the HD452D11 sliding bearing. Learn how its oil film and anti-vibration design protect feed pump shafts from wear under high-speed power plant loads.01-31

-

FA1D56A-00-1/4 Gasket: Fitting and Shock Protection for Pump Seal Chambers

Stop leaks in your feed pump seal water chamber. Learn how the FA1D56A-00-1/4 gasket matches your pump to resist pressure jumps and cavitation shocks.01-31