The Unsung Hero: Why the DLC200-8D-00 Coupling Bolt is Critical for Your Boiler Feed System

The Core Problem: Precision and Wear

In the power plant's boiler feedwater setup, the FA1D56-type booster pump is your water delivery manager, and the motor is the engine room heart powering it. For this pair to work together perfectly, they rely completely on one small, but mighty, piece: the DLC200-8D-00 Coupling Bolt. Let's talk about how this little bolt handles the big job of power transmission.

Understanding the Power Connector

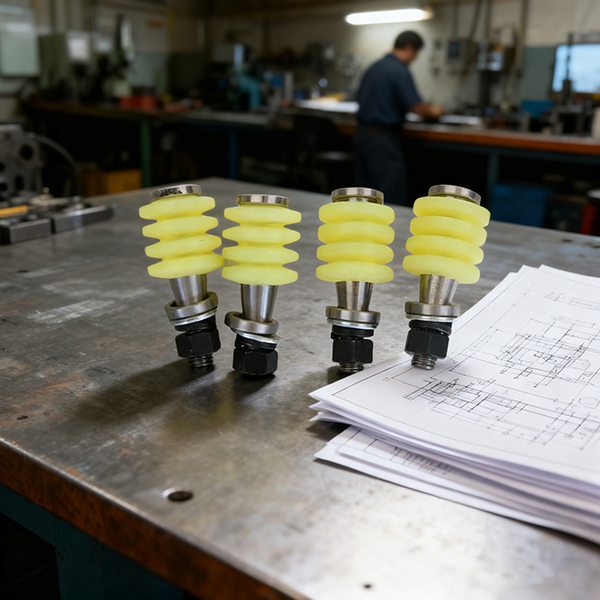

The DLC200-8D-00 coupling bolt isn't just any screw; it's a custom connector made exclusively for the FA1D56 booster pump. Put simply, its job is to tie the pump's "turntable" (the coupling half) and the motor's "turntable" tightly together. This ensures motor power smoothly transfers to the pump, guaranteeing water gets into the boiler without a hitch.

The material selection is serious business. It's forged from 35CrMo high-strength alloy steel and put through a special heat treatment—a process known in the industry as "quenching and high-temperature tempering." This specific material and process makes the bolt both tough and flexible. It can handle high-stress loads without deforming and adapts completely to the wild temperature swings common in a power station. It doesn't work alone, either; it partners with parts like the pump sleeve and thrust disk to maintain the pump's sealing integrity and power transfer precision.

What Makes It So "Overqualified"?

This small bolt has earned its place in the power station thanks to three core abilities:

1. Built Tough for Extreme Environments

Temperatures in the power plant fluctuate wildly. Near the boiler, it might hit 500°C in summer, while winter lows can be harsh. But the 35CrMo steel has a kind of superpower: it resists deformation well at high temps (what we call high creep strength) and won't suddenly become brittle when it's cold (good low-temperature toughness). No matter the external changes, it holds up the pressure of power transfer without "dropping the ball" because of temperature stress. Plus, the material properties match the pump's other parts perfectly, avoiding any coordination issues.

2. Precision Craftsmanship Saves You Trouble

The bolt's manufacturing process is super strict. First, the tempering treatment is done to balance strength and ductility, preventing fractures under long-term stress. Then, precision machinery cuts the threads, controls the length, and even checks the flatness of the end faces—the error margin is tiny. This means when you install it, the bolt fits the coupling hole snugly, avoiding uneven force distribution caused by poor sizing. A corrosion-resistant coating is also applied to reduce rust and wear, even in the humid, dusty plant environment, which helps cut down on maintenance time and costs.

3. High Compatibility, Fast Maintenance

This is the "custom edition" for the FA1D56 pump; the dimensions and interfaces align perfectly with the original design. When you swap it, there's no need for extra machining or adjustments—it's plug-and-play. For instance, during an overhaul, installing it alongside the thrust disk nuts and lock washers is fast, minimizing downtime. For the plant, this reduces maintenance hassles and simplifies inventory, since you don't need to stock a bunch of weird, special-spec parts.

Its Daily Work in the Power Plant

- Routine Inspection: Regular Checkups Keep Things Safe

Every day the plant runs, maintenance teams check this bolt: looking for looseness, rust, or cracks. If it loosens, power transfer between the pump and motor fails, leading to vibration, increased noise, and possibly compromising the water supply. A reliable bolt ensures smoother operation, so there's less constant worry about unexpected failure. - Emergency Repair: Fast Response Cuts Losses

If the booster pump suffers coupling misalignment or a power transmission failure, replacing this bolt is a critical step. By changing it along with the gaskets and pump sleeves, you quickly restore power transmission, slashing downtime. In winter, when water supply is critical, a fast fix ensures the boiler runs normally and avoids disrupting power and heat supply. - Spare Parts Stock: Be Prepared, Not Panicked

Power plants proactively keep these bolts in stock because they're consumables. If one suddenly fails, a ready spare means instant replacement—no waiting on vendor shipments. We also offer complementary parts like the sleeves and thrust disks, so the plant doesn't have to source them separately, making inventory management much easier.

Don't be fooled; the DLC200-8D-00 might be small, but it's the strong bond between the booster pump and the motor. Its reliability directly affects the stability of the plant's feedwater system, securing our daily power and water needs. Next time you think of power plant equipment, you might remember this quiet little "power relay agent."

Key Related Components

| Model | Name | Core Function |

|---|---|---|

| DLC200-8D-00 | Feedwater Pump/Motor Coupling Bolt | Core connector; links pump and motor couplings to transmit power. |

| FA1D56-01-06 | Pump Shaft Sleeve | Protects the shaft, reduces wear, ensures transmission precision with the bolt. |

| FA1D56-01-15 | Pump Shaft Sleeve | Works with other sleeves to enhance shaft sealing and stability. |

| FA1D56-01-05 | Pump Shaft Sleeve | Mates with pump body structure; assists sealing and power transfer. |

| FA1D56A | Feed Pump Turbine Oil Deflector | Prevents oil leakage, maintains lubrication of the transmission system. |

| FA1B56-A2-102779 | Thrust Disk | Balances shaft forces, prevents axial movement that impacts transmission. |

| FA1D56A-04 | Thrust Disk Nut | Secures the thrust disk, boosts transmission system stability. |

| FA1B56-A3-103403 | Thrust Disk Lock Washer | Prevents the nut from loosening, increases connection reliability. |

| FA1B56-A3-103332 | Thrust Disk Key | Connects the thrust disk to the pump shaft, ensuring synchronized rotation. |

| FA1D56-03-09 | Gasket | Seals pump body joints; works with bolts to ensure overall sealing performance. |

Ready to Eliminate Coupling Failures? Talk to the Experts.

Is coupling bolt failure causing your unacceptable downtime? Don't settle for generic hardware!

Click here now to request a quotation on upgrading your FA1D56 pump hardware to the high-spec DLC200-8D-00. Check our real-time stock status. We ship reliable power transmission components tailored for your plant's demands.

HKCYT-2025-11-12

-

Stop Booster Pump Leaks: Master the HZB253-640-01-05 Oil Flinger Install

Stop lube oil leaks. Learn how to control the HZB253-640-01-05 oil flinger gap, why install direction matters, and how to match its life to your bearing overhaul.02-25

-

Why Re-using the HZB253-640-01-03 Locking Washer Risks Total Booster Pump Failure

Don't let bolts come loose. Learn how to check the HZB253-640-01-03 locking washer for fatigue, why you shouldn't re-use it, and how to install it right.02-04

-

Stop Pump Leaks: A Maintenance Guide for the HZB253-640-01-13 Shaft Sleeve

Prevent booster pump shutdowns. Learn how to spot HZB253-640-01-13 shaft sleeve erosion, pitting, and vibration issues before they ruin your mechanical seals.02-02

-

Stability Principles of the HD452D11 Sliding Bearing Under Extreme Dynamic Loads

Master the HD452D11 sliding bearing. Learn how its oil film and anti-vibration design protect feed pump shafts from wear under high-speed power plant loads.01-31

-

FA1D56A-00-1/4 Gasket: Fitting and Shock Protection for Pump Seal Chambers

Stop leaks in your feed pump seal water chamber. Learn how the FA1D56A-00-1/4 gasket matches your pump to resist pressure jumps and cavitation shocks.01-31