The Evolution of a Power Plant Sealing Veteran: A Full Breakdown of the HZB253-640-03-06 Gasket

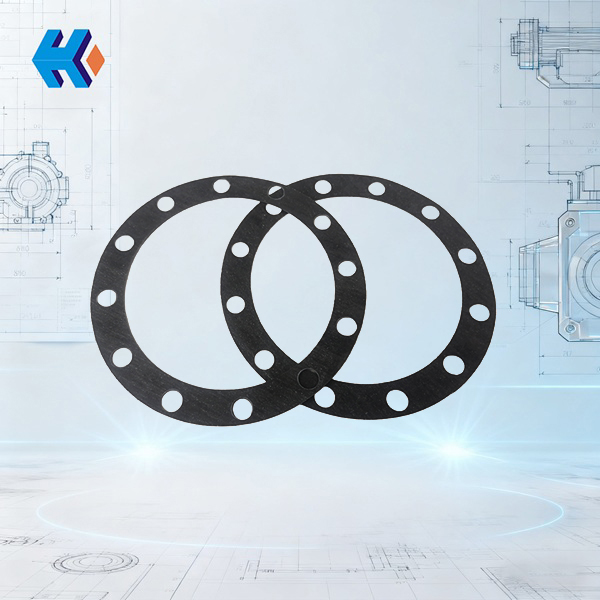

In the large-scale power station's water supply heart—the boiler feed system—the booster pump acts as the pressure regulator, ensuring the main feed pump gets stable water pressure. The static sealing system is its waterproof coat, and the HZB253-640-03-06 Gasket is a critical button on that coat, guarding the pump body joints against leaks of high-temperature, high-pressure water and steam. Today, let's discuss the past, present, and maintenance secrets of this sealing veteran.

I. Core Sealing Components: Who Guards the Booster Pump?

A gasket never works in isolation; it forms a defense line with a series of associated components. Let's meet the core members:

| Model | Component Name | Core Function |

|---|---|---|

| HZB253-640-03-06 | Booster Pump Gasket | Primary static sealing element; seals gaps in pump body split-lines, end covers, etc. |

| HZB253-640-02-01 | O-ring | Used with shaft sleeves to prevent lubricating oil leakage and contamination of sealing faces. |

| HZB253-640-03-24 | Metal/Spiral Wound Gasket | Seals high-pressure interfaces like main inlet/outlet pipe connections. |

II. The Pros and Cons of Asbestos Gaskets: Traditional Sealing's Two Faces

The most common traditional material for the HZB253-640-03-06 gasket was heat-resistant asbestos sheet. In older technical contexts, it was a hot item:

- High Heat and Corrosion Resistance: It worked stably in 160–200°C conditions and handled boiler feed water and steam without flinching, avoiding easy swelling or degradation.

- Simple and Reliable Sealing Principle: Sealing was achieved by the pressure from tightened bolts, compressing the asbestos sheet to conform to the sealing faces, filling tiny pits and irregularities.

- Cost-Effective: Material and processing costs were low, leading to widespread industrial use.

However, as environmental and health awareness grew, the flaws of asbestos gaskets became glaring:

- Health Invisible Killer: Asbestos fibers, once airborne and inhaled, harm the respiratory system, posing risks during production, replacement, and disposal.

- Poor Endurance: It lacks elasticity and tends to relax when temperature and pressure fluctuate, leading to reduced sealing effectiveness.

- Short Lifespan: Prolonged high temperatures cause brittleness, requiring frequent replacement and increasing maintenance expenses.

Newer materials like flexible graphite and aramid fibers are now highly recommended alternatives, as they are both environmentally friendly and extend overhaul cycles.

III. Sealing Isn't a Solo Act: System Synergy is Key

Many people assume a good gasket fixes everything, but sealing is an engineering system. For example:

- Impeller Imbalance Undermines Sealing: If the impeller (HZB253-640-01-08) or double-suction impeller (GNPD-HZB253-640A-01-01) runs unstably, the pump body vibrates. Over time, the gasket will be shaken loose, causing a leak.

- Damaged Flange Faces Leak: Even with the best gasket, if the pump body flange face has scratches or deformation, it's like using a new cork to plug a cracked bottle—it will definitely leak.

- Incorrect Bolt Tightening is Useless: Uneven bolt tightening means the gasket is stressed unevenly; some areas won't be compressed tightly enough, inevitably leading to leakage.

IV. Maintenance Guide: The Right Way to Change a Gasket

Replacing a gasket is routine work in plant maintenance, but mistakes often force a re-do. The correct procedure is:

- Gentle Old Gasket Removal: Use a plastic scraper to clean off the old gasket and residue. Never use hard metal tools, as they can scratch the flange face, creating a leak path for the new gasket.

- Flange Face Health Check: Carefully inspect for scratches, pits, or corrosion. Minor defects should be smoothed with a fine oilstone; severe damage requires component replacement.

- New Gasket Installation Details: Confirm the model and dimensions match. A thin layer of media-compatible sealant can be applied to the surface, which improves the seal and makes future disassembly easier.

- Bolt Tightening Technique: Use a torque wrench, applying force based on the diagonal-cross, multi-stage principle. For instance, tighten the top-left, then the bottom-right, gradually increasing force to the specified torque. This ensures the gasket is compressed evenly.

V. Coordinated Inspection Spares: What to Check During Replacement

When replacing a gasket, we advise checking the following parts simultaneously to achieve one repair, long-term peace of mind:

| Model | Component Name | Inspection Focus |

|---|---|---|

| HZB253-640-01-11 | Lock Nut | Check for looseness; ensure the impeller and other components are reliably secured. |

| HZB253-640-01-14 | Lock Washer | Check for deformation; verify its anti-loosening function. |

| HZB253-640-01-03 | Stop Washer | Check integrity; prevents nuts from self-loosening. |

| HZB253-640-01-05 | Oil Slinger Ring | Check integrity; prevents lubricant oil from leaking and contaminating sealing faces. |

These components might seem unrelated to the static seal, but their condition indirectly affects sealing effectiveness. For example, a damaged oil slinger causes oil leakage, which can contaminate and compromise the gasket. These parts shouldn't wait until total failure; address any signs of wear promptly to minimize future faults.

Conclusion: Small Gasket, Big Responsibility

The HZB253-640-03-06 gasket is small but directly impacts a power station's safety and efficiency. Its evolution—from traditional asbestos to new composite materials—reflects the industry trend toward safety first, environmental upgrade. Crucially, scientific maintenance and overhaul—not just replacing the gasket well, but inspecting the entire system—are the keys to making the booster pump drip-proof.

Next time you perform maintenance, take note of this quietly dedicated sealing veteran. Choosing the right material and executing proper maintenance will allow it to ensure the stable operation of your power station.

HKCYT-2025-11-17

-

Stop Booster Pump Leaks: Master the HZB253-640-01-05 Oil Flinger Install

Stop lube oil leaks. Learn how to control the HZB253-640-01-05 oil flinger gap, why install direction matters, and how to match its life to your bearing overhaul.02-25

-

Why Re-using the HZB253-640-01-03 Locking Washer Risks Total Booster Pump Failure

Don't let bolts come loose. Learn how to check the HZB253-640-01-03 locking washer for fatigue, why you shouldn't re-use it, and how to install it right.02-04

-

Stop Pump Leaks: A Maintenance Guide for the HZB253-640-01-13 Shaft Sleeve

Prevent booster pump shutdowns. Learn how to spot HZB253-640-01-13 shaft sleeve erosion, pitting, and vibration issues before they ruin your mechanical seals.02-02

-

Stability Principles of the HD452D11 Sliding Bearing Under Extreme Dynamic Loads

Master the HD452D11 sliding bearing. Learn how its oil film and anti-vibration design protect feed pump shafts from wear under high-speed power plant loads.01-31

-

FA1D56A-00-1/4 Gasket: Fitting and Shock Protection for Pump Seal Chambers

Stop leaks in your feed pump seal water chamber. Learn how the FA1D56A-00-1/4 gasket matches your pump to resist pressure jumps and cavitation shocks.01-31