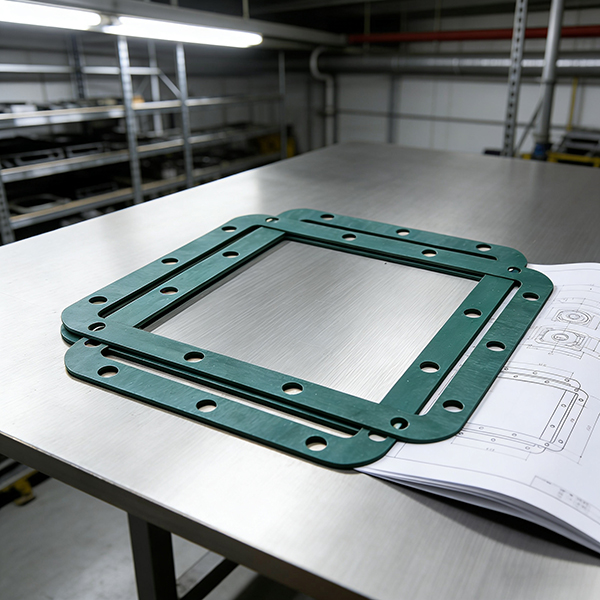

Gasket HZB253-640-02-07: The Hidden Guard for the Booster Pump Seal

Inside the HZB253-640 boiler booster pump seal system, the HZB253-640-02-07 gasket looks like nothing important. But it's actually the main line against leaks. It sits where the pump body and the end cover meet. It stops the pump's high-pressure stuff from leaking out, and keeps dirt from getting into the seal area. Don't think this little pad is minor. If it fails, you get waste and lost energy. Worse, it can ruin equipment and even force the pump to stop. Lots of power plants paid big money because of this. They had to switch to the right spares to get things working.

I. Made to Fit: The Pump's Perfect Match

This gasket is only for the HZB253-640 boiler booster pump. Size, fit, and sealing quality are all made to the pump's official repair manual. A general gasket won't work. Even small sizing mistakes mean it either doesn't fit or it leaks.

It works with other gaskets in its series, making a multi-layer seal. Different models manage different spots (like HZB253-640-03-01, HZB253-640-03-06). Each one keeps its own area sealed, making the whole system safe. When we send these out, we check the sizes against the cooling jacket HZB253-640-03-10 and its cover HZB253-640-01-00. The whole assembly must seal tight.

| Part Type | Item Name | Model | Where it Fits / Job |

|---|---|---|---|

| HZB253 Gaskets | Gasket | HZB253-640-02-07 | Pump body to end cover, the main defense line |

| Gasket | HZB253-640-03-01 | Secondary seal point on pump body | |

| Gasket | HZB253-640-03-06 | Auxiliary seal in the seal chamber | |

| Related Parts | Cooling Jacket | HZB253-640-03-10 | Cools the seal, helps gasket manage heat |

| Cooling Jacket Cover | HZB253-640-01-00 | Holds the jacket, helps position the gasket | |

| Full Seal Parts | Metal Wound Gasket | HZB253-640-03-24 | High-pressure spot, works with gasket for double seal |

| Oil Seal Assembly | HZB253-640A-02-01-00 | Shaft end seal, completes the sealing system |

II. Built Tough: Secrets in the Material and How It's Made

The material is genuine, high-temp asbestos fiber. Tests show it handles up to 500°C. The pump usually runs at about 280°C. This means the gasket has huge safety room. It won't get hard or fail like cheap pads do when they get hot. One plant used common pads and leaked in under 3,000 hours. Switching to this one more than doubled their run time.

The design is smart, too. The sealing surface has a smooth finish, roughness is under Ra 0.8μm. It sits on the pump body surface, making contact better than 99.5%. Almost zero space for leaks. The edges are curved. This stops the sides from being crushed or ripped under uneven pressure. This edge failure is a common gasket problem, and this design avoids it.

It resists squash. Even after working long-term under high pressure, the permanent compression set is only 5%. This means it stays springy and won't cave in after a long time. No need for changing it often.

Production is strict. First molded, then high-temp cured. This makes the inside very dense. Every batch must pass three tests: air tightness, high-temp aging, and compression recovery. All must meet the HZB253-640 repair manual standards. Nothing bad gets out. Dongfang SRI focuses on every small step to make sure power plants can rely on this spare.

III. In Service: When to Change and How to Keep It Running Smoothly

The HZB253-640 booster pumps in power plants use this part to stop leaks. The pump moves hot, high-pressure water. Without this gasket, the leaking water is wasteful and attacks the pump body. Repairs get much harder. When this is installed, leakage stays within limits, keeping the water system steady.

During overhaul, this gasket must be checked and replaced. The manual says change it after 6,000 hours, or if you see even small leaks. Since the size is perfect, you just take the old one out and put the new one in. No extra work on the pump surface is needed. This saves a lot of repair time—and time is money when a plant is down.

Installation needs care: Clean the surfaces well. Remove old gasket bits, rust, and oil. Even one tiny piece of dirt can start a leak. Tighten the bolts in a cross pattern. Do it in steps, don't just tighten one fully at once, and don't tighten them one after the other. Uneven force can crush the gasket.

Old plants use this for upgrades. If an old pump leaks often, using the HZB253-640-02-07 gasket boosts sealing without changing the pump structure. We also supply the full set of related parts, like the metal wound gasket HZB253-640-03-24 and the oil seal assembly HZB253-640A-02-01-00. We solve the whole sealing problem at once. This often stretches the pump's overhaul time from 6,000 hours to over 10,000 hours.

Booster pump sealing isn't hard. Choose the right, specialized spare parts, follow standard procedures for installation, and check it often. Failures drop fast. Dongfang SRI has the HZB253-640-02-07 gasket in stock, gives repair help, and can quickly respond to normal changes or emergency needs. Seal problems won't stop your equipment.

KHCYT-2025-12-04

-

Stop Booster Pump Leaks: Master the HZB253-640-01-05 Oil Flinger Install

Stop lube oil leaks. Learn how to control the HZB253-640-01-05 oil flinger gap, why install direction matters, and how to match its life to your bearing overhaul.02-25

-

Why Re-using the HZB253-640-01-03 Locking Washer Risks Total Booster Pump Failure

Don't let bolts come loose. Learn how to check the HZB253-640-01-03 locking washer for fatigue, why you shouldn't re-use it, and how to install it right.02-04

-

Stop Pump Leaks: A Maintenance Guide for the HZB253-640-01-13 Shaft Sleeve

Prevent booster pump shutdowns. Learn how to spot HZB253-640-01-13 shaft sleeve erosion, pitting, and vibration issues before they ruin your mechanical seals.02-02

-

Stability Principles of the HD452D11 Sliding Bearing Under Extreme Dynamic Loads

Master the HD452D11 sliding bearing. Learn how its oil film and anti-vibration design protect feed pump shafts from wear under high-speed power plant loads.01-31

-

FA1D56A-00-1/4 Gasket: Fitting and Shock Protection for Pump Seal Chambers

Stop leaks in your feed pump seal water chamber. Learn how the FA1D56A-00-1/4 gasket matches your pump to resist pressure jumps and cavitation shocks.01-31