Induced Draft Fan Servo Valve Connecting Rod HU25238-22: Failure Analysis and Mitigation

From Crisis Response to Long-Term Prevention: A Comprehensive Solution to Connecting Rod Fracture

Let's face it: the induced draft (ID) fan's dynamic adjustment connecting rod—let's just call it the link—is a tiny powerhouse. It's the critical transmission component that bridges the hydraulic actuator with the variable pitch vane (or dynamic blade) control system. Its job? To transmit the necessary torque for precise flow regulation. When this small but mighty piece snaps, the result is anything but minor. Vane angle control immediately fails, forcing an emergency fan shutdown, severely compromising the unit's safety and stable operation, and potentially triggering a nasty cascade of equipment failures. You really don't want that.

Root Cause Analysis: Tracing the Breakdown

Connecting rod fractures usually aren't a single-event drama; they're often the culmination of one or more contributing factors. Identifying the "who, what, and why" is the first step to a permanent fix.

1. Fatigue is the Main Culprit

This is the big one. During operation, the link is constantly battered by complex, cyclic stresses and vibrational loads. Over a long service life under these repetitive loads, micro-cracks inevitably form within the material and gradually grow. Eventually, they reach a critical size, leading to catastrophic fatigue fracture. These failures are particularly prone to occurring at stress concentration points—think the root of threads or where the cross-section changes dramatically. It's like a paperclip you bend back and forth too many times.

2. Abnormal Load Shock

Sometimes, the system just gets hit with a massive, unexpected jolt. Events like ID fan stalling or extreme fluctuations in oil pressure can subject the connecting rod to impact loads far exceeding its design capacity. This abnormal loading almost always results in sudden overload fracture.

3. Corrosion and Wear-Induced Weakness

Operating in harsh industrial environments is tough. The link's surface can suffer from corrosion, or its connection points can experience excessive abrasion. Either way, the effective cross-sectional area—and thus the load-bearing capacity—is diminished. Once weakened, the link can fail even under normal operating conditions.

Solutions and Steps: A Systemic Response Strategy

When a fracture occurs, the response must be immediate, methodical, and safe.

A broken dynamic adjustment link mandates an immediate, unplanned shutdown of the ID fan. Since pitch control is lost, the critical next step is closing the ID fan’s inlet electric damper. This is a high-risk maneuver, so watch out for these major pitfalls:

- Preventing Stall and Backdraft: While gradually closing the damper, you must meticulously monitor the fan’s status to prevent it from stalling and to avoid a dangerous draft-fight (or 'robbing') between the two operating ID fans.

- Stabilizing the Hydraulic System: A fan stall can cause massive oil pressure swings, potentially disrupting the balance within the dynamic adjustment servo valve oil chambers, leading to the vanes suddenly snapping shut.

- Controlling Negative Pressure: Keep a hawk-eye on the negative pressure at the ID fan inlet. It absolutely must not exceed the duct's design pressure limit (e.g., -7.176 KPa) to avoid catastrophic flue gas duct damage.

- Avoiding Prolonged Low-Load Operation: Don’t let the ID fan run too long at low output with a very small inlet damper opening, as this is terrible for the equipment.

- Standardizing Isolation Procedures: Stick rigorously to the standard operating procedures when isolating the fan to prevent an avoidable trip.

Once the immediate crisis is managed, the real work of repair begins.

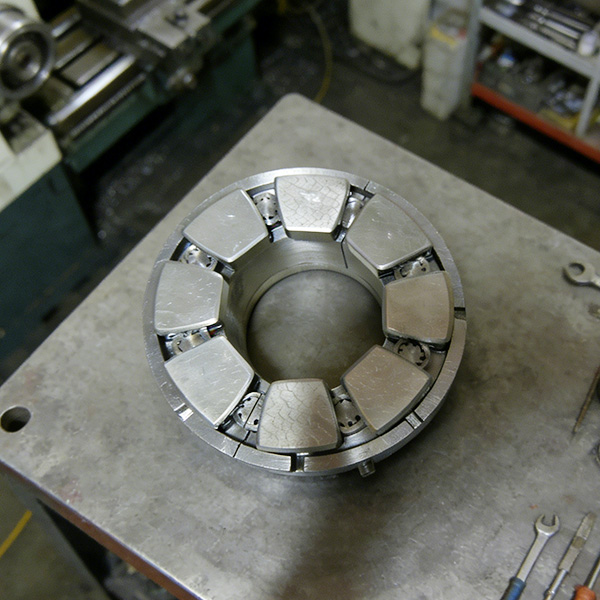

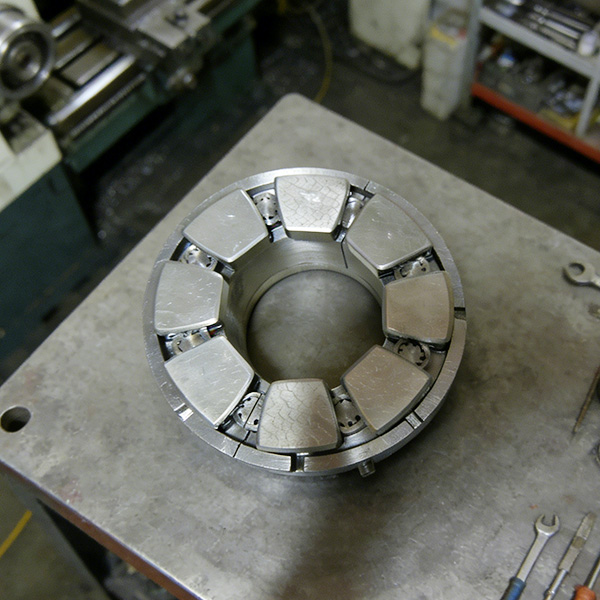

- System Disassembly Check: Thoroughly dismantle and inspect the hydraulic actuator.

- Non-Destructive Testing (NDT): Subject related components to magnetic particle or ultrasonic testing. You need to catch those hidden cracks!

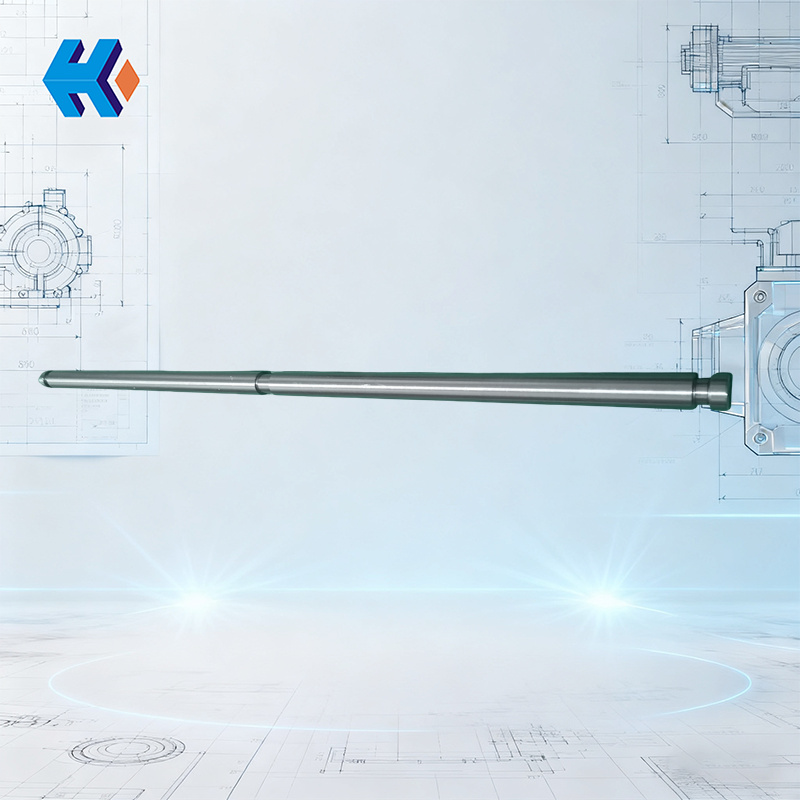

- Damaged Part Replacement: Replace the fractured link and any associated damaged parts. Here, we strongly recommend using the specified Servo Valve Connecting Rod HU25238-22.

Introducing the HU25238-22 Upgrade: Your Fatigue Fix

We strongly endorse the use of our specialized Induced Draft Fan Servo Valve Connecting Rod HU25238-22. We engineered this product specifically to defeat the common failure modes:

- Material Overhaul: It utilizes a high-strength alloy steel, put through a specialized heat treatment process. Result? Fatigue strength is boosted by over 30%.

- Structural Optimization: We've cleverly redesigned the notorious stress concentration areas, significantly extending the service life.

- Precision Guaranteed: Tight, precision machining ensures perfect fit and alignment, which minimizes abnormal wear and tear.

- Reliability: Every batch comes with complete material and heat treatment certifications. No guesswork.

Switching to the HU25238-22 effectively eliminates the problem of uncontrollable dynamic blade angle, ensuring your control system runs reliably—and quietly.

Given that the ID fan is a piece of high-precision kit, a bulletproof maintenance plan is non-negotiable.

- Regular Cleaning: Stay on top of cleaning—sensors, filters, cooling seal fan screens, and overflow pipe grids all need timely attention.

- Fastener Checks: Periodically inspect and tighten all bolts and threaded connections. If it moves, secure it.

- Lubrication Management: A typical schedule involves lubrication inspection six times per month to ensure proper oil application.

- Scheduled Overhauls: Implement both planned and non-planned outages based on the fan's operating cycle for essential maintenance.

Proactive Improvement Measures: Looking Ahead

To truly transition from firefighting to fire prevention, consider these upgrades:

- Monitoring Systems: Install vibration and stress monitoring sensors on key components. Knowledge is power.

- Operational Procedures: Fine-tune the fan start-up and shut-down procedures to minimize the chance of those stress-inducing abnormal conditions.

- Scheduled Component Replacement: Establish a strict, preventive replacement schedule for critical components, including the Servo Valve Connecting Rod HU25238-22. Don't wait for it to break.

- Operator Training: Intensify training for operating staff to sharpen their skills in handling abnormal conditions.

-

Balance Drum DG600-240VM: How It Handles High Pressure and Why Your Maintenance Matters

Learn how the DG600-240VM balance drum regulates axial thrust in 600MW feed water pumps. Includes maintenance tips, clearance specs, and O-ring seal checklists.01-09

-

Feed Water Pump Guide Vane DG600-240-04-13 Maintenance Tips & Parts Checklist

Improve feed water pump efficiency. Learn the 6-step overhaul for DG600-240-04-13 guide vanes, plus a critical checklist for bushings, pins, and O-ring seals.01-08

-

Thrust Disc DG600-240-03-22A: Why it’s the Key to Your Feed Water Pump Overhaul

Stop rotor float and vibrations in your FK6D32 pump. Learn the assembly secrets, heat treatment benefits, and 4-step installation for the DG600-240-03-22A disc.01-07

-

Maintenance FAQ: The SD61H-P61 Self-Seal Ring—Why Your Blocking Valve Still Leaks After You Fixed It

Stop blocking valve leaks. Learn the 2mm gap secret and correct assembly for SD61H-P61 sealing rings, backing rings, and split rings in 300MW-600MW units.01-06

-

Feed Water Pump Inner Cartridge Nut DG600-240-01-07: Small Component, Critical Role

Avoid feed pump vibration and axial shifting. Master the torque, direction, and maintenance pitfalls of the DG600-240-01-07 cartridge nut for FK6D32M pumps.01-05