Thrust Disc DG600-240-03-22A: Why it’s the Key to Your Feed Water Pump Overhaul

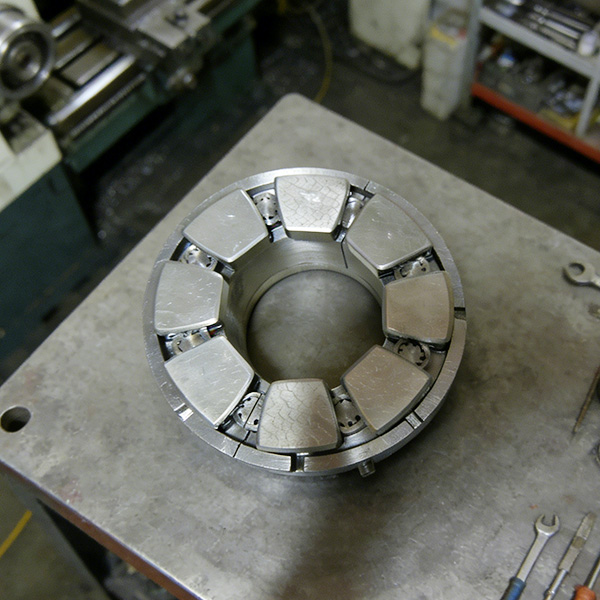

In a power plant or a nuclear facility, the FK6D32 steam-driven feed water pump is a massive piece of machinery that has to work perfectly 24/7. Inside that pump, there is a lot of pressure and a lot of movement. The part that handles all that pushing force is the Thrust Disc DG600-240-03-22A.

Its job sounds simple: it stops the pump rotor from moving too far forward or backward (what we call axial thrust). If this disc isn't doing its job, the rotor will start shuttling or floating too much. When that happens, you get vibrations, heat alarms, and eventually, a total pump failure. That is why during any major overhaul, the thrust disc is usually the first thing we look at.

The Team: Parts That Work with the DG600-240-03-22A

One thing you need to know right away is that you can't just swap the thrust disc and call it a day. The FK6D32 Maintenance Manual is very clear: this disc needs its team of matching parts to work. If you put a new disc in with old, flattened O-rings or a worn-out oil deflector, you are just asking for a leak or a bearing failure in a few weeks.

| Matching Part Name | Model Number | Why you need it |

|---|---|---|

| O-Ring | DG600-240-07-01(1) | Stops lube oil from leaking out. If oil leaks, the disc gets dry and hot. |

| Oil Deflector | DG600-240-05-04 | Keeps the dirty medium away from the clean lube oil. |

| Radial Bearing Cap | DG600-240-05-01 | This is the base. If the cap is warped, the disc will never sit straight. |

| Balance Pipe | DG600-240-01-05-00 | This helps carry some of the load so the disc doesn't have to do all the work alone. |

I. Why This Disc is Tougher Than It Looks

You might look at the DG600-240-03-22A and think it's just a piece of steel, but there is a lot of engineering in it. It's made from 45# Carbon Steel, which is standard for high-strength parts, but it goes through two very important heat treatments:

- Quenching and Tempering (Q&T): This makes the whole disc tough. You don't want the steel to be brittle; it needs to be able to take a hit or a sudden pressure spike without cracking into pieces.

- Surface Induction Hardening: The flat surface—the part that actually rubs against the thrust pads—goes through induction hardening. This makes the surface very hard and slick, which is what allows it to spin at thousands of RPMs for months at a time without wearing down.

II. Maintenance: Getting the Job Done Right

When should you replace it? Usually, there are two times. The first is an Emergency Repair (vibrations or heat alarms). The second is a Scheduled Overhaul. Most plants replace the thrust disc every few years just to be safe.

Step 1: Before You Take it Apart

First, you need to measure the Rotor Float. This is the amount of room the rotor has to move back and forth. Write this number down! You will need it later to make sure the new disc is installed correctly.

Step 2: Taking Out the Old Disc

Use the right pullers. Don't grab a sledgehammer and start beating on the shaft. You can easily bend the shaft neck or damage the rotor if you are too rough. Pull the disc out smoothly. Once it's out, look at the face of it. If you see deep scratches or rainbow colors (heat tint), it means the pump was running hot.

Step 3: Putting in the New Disc

Check the fit. The DG600-240-03-22A is a precision part, so it should slide on perfectly. Always, always use brand-new O-rings. Even if the old ones look okay, they have probably lost their spring and won't seal properly under high pressure.

Step 4: The Final Check

Tighten the bolts to the torque specs in the manual. Now, measure the rotor float again. If it's too tight, the pump will overheat. If it's too loose, the rotor will vibrate. Finally, turn the pump shaft by hand (barring). It should feel smooth.

III. Why Procurement Matters

Buying a generic thrust disc is a bad idea. If the disc is off by even a fraction of a millimeter, the disc can fail. Dongfang SRI provides the DG600-240-03-22A made exactly to original factory specs. We don't just send the disc; we can send the O-rings, the oil deflectors, and the breathers all in one kit.

Summary: Replacing a thrust disc is about protecting the heart of your plant. By using high-quality parts and following the right steps—measuring clearance and checking heat treatment—you can keep your FK6D32 pumps running for years.

HKCYT-2026-01-07

-

Stop Booster Pump Leaks: Master the HZB253-640-01-05 Oil Flinger Install

Stop lube oil leaks. Learn how to control the HZB253-640-01-05 oil flinger gap, why install direction matters, and how to match its life to your bearing overhaul.02-25

-

Why Re-using the HZB253-640-01-03 Locking Washer Risks Total Booster Pump Failure

Don't let bolts come loose. Learn how to check the HZB253-640-01-03 locking washer for fatigue, why you shouldn't re-use it, and how to install it right.02-04

-

Stop Pump Leaks: A Maintenance Guide for the HZB253-640-01-13 Shaft Sleeve

Prevent booster pump shutdowns. Learn how to spot HZB253-640-01-13 shaft sleeve erosion, pitting, and vibration issues before they ruin your mechanical seals.02-02

-

Stability Principles of the HD452D11 Sliding Bearing Under Extreme Dynamic Loads

Master the HD452D11 sliding bearing. Learn how its oil film and anti-vibration design protect feed pump shafts from wear under high-speed power plant loads.01-31

-

FA1D56A-00-1/4 Gasket: Fitting and Shock Protection for Pump Seal Chambers

Stop leaks in your feed pump seal water chamber. Learn how the FA1D56A-00-1/4 gasket matches your pump to resist pressure jumps and cavitation shocks.01-31