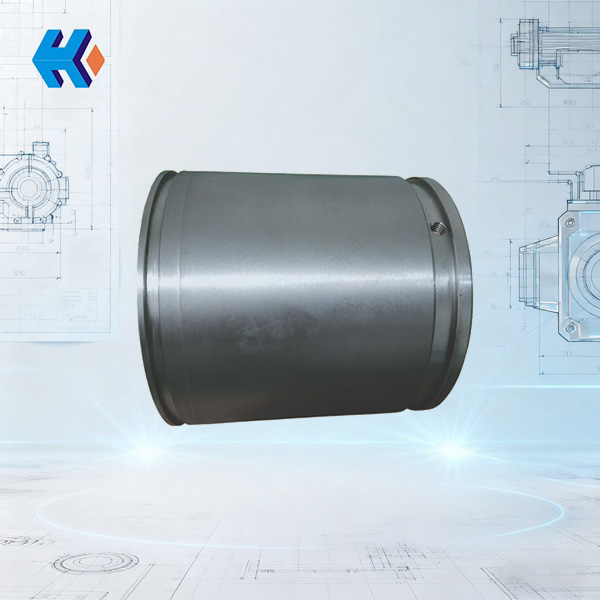

HPT300-340-6S/27 Guide Vane Bushing Hardness Challenge: Dongfang SRI's Solution to Protect Feedwater Pump

Has your HPT300-340 feedwater pump suddenly experienced a plunge in head or an excessive surge in vibration, only for disassembly to reveal that the culprit was a guide vane bushing with substandard hardness matching? If so, you may not realize that this seemingly minor component is quietly draining your power generation efficiency and inflating your maintenance costs.

1. The HPT300-340 Feedwater Pump: The "Invisible Threat" of Guide Vane Bushing Hardness Mismatch

For the HPT300-340 pump, the material hardness differential of the guide vane bushing HPT300-340-6S/27 is far more than a simple "specification compliance" issue. It directly determines the "wear balance between the rotating and static components" within the pump. It must meet two fundamental requirements simultaneously:

- Maintain a precise hardness differential with the impeller bushing to prevent unilateral, excessive wear.

- Withstand the harsh operational impact of high temperature 185.58°C and high pressure 37 MPa.

In reality, many bushings suffer from two common failures: either the hardness is too high, leading to excessive wear on the impeller, or the hardness is too low, causing the bushing itself to rapidly erode. This necessitates replacement in a short 1–2 year period and often causes cascading failures in the balance drum and thrust bearing. Consequently, pump efficiency can plummet from the design 84% to below 75%, and fluctuations in extraction pressure threaten the safety of the reheater attemperator water supply.

2. Recurring Hardness Problems? The Roots Lie in Three "Blind Spots"

- Substandard Material Substitution: Some suppliers compromise material quality to cut costs, using materials with insufficient chromium content (below 11%), leading to a continuous drop in hardness under high temperatures.

- Process Control Failure: Inaccurate heat treatment results in a hardness differential exceeding 5 HRC within the same bushing, creating localized "wear hotspots."

- Incomplete Inspection: Only the hardness of the bushing end face is tested, while critical areas like the inner wall and mating surfaces are overlooked. This leads to in-service failure due to component incompatibility despite initial superficial compliance.

3. Dongfang SRI: Custom Solutions Moving from "Reactive Fix" to "Long-Term Stability"

3.1 Case Study: The "Renewal" Proof for a 660MW Unit

A power plant operating a 2 × 660 MW unit faced a recurring problem: their HPT300-340 feed pump's guide vane bushings failed to meet hardness specifications. This resulted in impeller bushing wear-out in just six months, causing pump efficiency to drop by six percentage points.

After replacing the faulty parts with the Dongfang SRI HPT300-340-6S/27 Guide Vane Bushing, the unit achieved three major breakthroughs over an 18-month period:

- Impeller bushing wear was minimal, measured at only 0.02 mm.

- Pump efficiency stabilized at a high 83.5%.

- Extraction pressure was precisely maintained at 16.07 MPa.

3.2 Three "Hard-Core" Strategies: Solving the Hardness Mismatch Challenge

- Custom Material Selection: Utilizing stainless steel forged parts with 12–13% Chromium and 2–3% Molybdenum, and incorporating Titanium elements to boost high-temperature stability. The resulting hardness differential is precisely matched to the impeller bushing.

- Precise Process Control: Employing segmental quenching followed by low-temperature tempering, with temperature precisely controlled between 1050°C and 1080°C. This ensures a hardness uniformity error of ≤ 2 HRC, completely eliminating internal stresses.

- Full Inspection Guarantee: Utilizing ultrasonic hardness testers to scan the inner wall and mating surfaces. The bushings are subjected to a "paired inspection" with the impeller and throttle bushings to eliminate issues where individual parts are compliant but incompatible as an assembly. Ensure your pump runs at peak efficiency! Contact Dongfang SRI for a professional hardness analysis and customized bushing quote.

4. More Than Just Guide Vane Bushings: Comprehensive Bushing Supply

Dongfang SRI covers the entire spectrum of bushing requirements for the HPT300-340 pump and all power station applications. We eliminate the compatibility issues that arise from sourcing parts from multiple suppliers by maintaining a unified process standard. Key products are detailed in the table below:

| Bushing Type | Model | Core Advantage | Application Scenario |

|---|---|---|---|

| Throttle Bushing | 522.01 | Wear-resistant, anti-leakage, designed for 37 MPa pressure. | Balance Drum System |

| Pre-tightening Bushing | 3GA6474A | Strong anti-deformation ability, ensuring single-pass sealing of the inner casing. | Casing Pre-tightening |

| Interval Bushing | 4GA13670b | Dimensional accuracy ±0.01 mm, minimum hydraulic loss. | Interstage Flow Path Clearance Control |

| Gap Bushing | 4GA141816 | Pre-calculates shaft train thermal expansion, preventing axial seizure. | Shaft Train Thermal Expansion Compensation |

| Fan Blade Bolt Bushing | 4TY0003 | High resistance to vibration fatigue. | Primary Air Fan System |

| Fan Blade Bolt Bushing | 4TY0006 | Resistant to flue gas corrosion, surface smoothness Ra ≤ 0.8 μm, reduces air resistance by 10%. | Forced Draft Fan System |

| Bearing Interval Bushing | FAF26.6-15-1 | End-face flatness error ≤ 0.008 mm/m, stable clearance control. | Bearing Positioning |

| Guide Vane Bushing | HPT300-340-04-04 | Adapts to various stages, precise hardness differential matching. | HPT300-340 Pump Interstage Flow Guidance |

| Sliding Bushing | MB2030Du, MB4111030Du | Self-lubricating (MB2030Du), high-load durability (MB4111030Du). | Shaft Train Sliding Components |

| Screw Bushing | S4GA4263 | Protects screws, anti-corrosion and wear protection. | Component Screw Protection |

| Low-Pressure Pipe Spacer | S4GA0308 | Adapts to low-pressure piping, precise dimensioning. | Low-Pressure Piping Clearance Control |

5. A "Long-Term Guarantee" for Your Pump

For any power plant, the stability of the feedwater pump is the baseline for generation efficiency. The Dongfang SRI HPT300-340-6S/27 Guide Vane Bushing is more than just a replacement part; it equips your pump with a "Long-Term Protective Shield":

- Expected lifespan exceeds 6 years, far surpassing the industry standard replacement cycle of 1–2 years.

- Operating costs are cut by 3–5 times, reducing losses from shutdown maintenance.

- Full range of bushings sourced from one place, simplifying procurement and eliminating compatibility headaches.

Don't let a small bushing create a massive problem. Dongfang SRI's customized bushing solutions are ready to safeguard your HPT300-340 feedwater pump at any time.

-

Stop Booster Pump Leaks: Master the HZB253-640-01-05 Oil Flinger Install

Stop lube oil leaks. Learn how to control the HZB253-640-01-05 oil flinger gap, why install direction matters, and how to match its life to your bearing overhaul.02-25

-

Why Re-using the HZB253-640-01-03 Locking Washer Risks Total Booster Pump Failure

Don't let bolts come loose. Learn how to check the HZB253-640-01-03 locking washer for fatigue, why you shouldn't re-use it, and how to install it right.02-04

-

Stop Pump Leaks: A Maintenance Guide for the HZB253-640-01-13 Shaft Sleeve

Prevent booster pump shutdowns. Learn how to spot HZB253-640-01-13 shaft sleeve erosion, pitting, and vibration issues before they ruin your mechanical seals.02-02

-

Stability Principles of the HD452D11 Sliding Bearing Under Extreme Dynamic Loads

Master the HD452D11 sliding bearing. Learn how its oil film and anti-vibration design protect feed pump shafts from wear under high-speed power plant loads.01-31

-

FA1D56A-00-1/4 Gasket: Fitting and Shock Protection for Pump Seal Chambers

Stop leaks in your feed pump seal water chamber. Learn how the FA1D56A-00-1/4 gasket matches your pump to resist pressure jumps and cavitation shocks.01-31