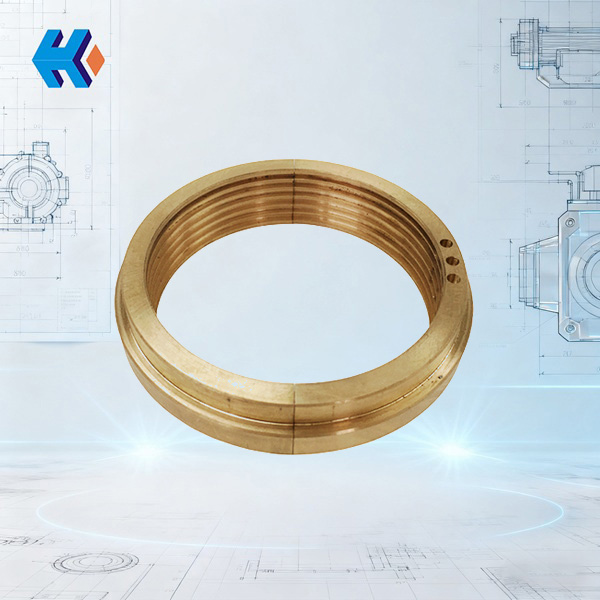

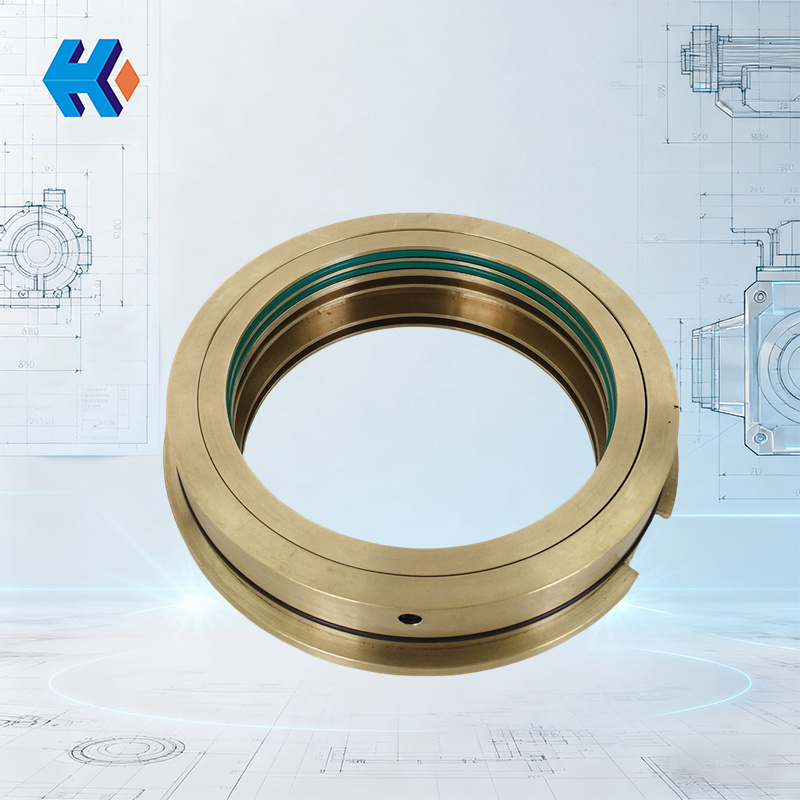

Booster Pump Oil Deflector Ring FA1B56-A2-102761A: Guarding the Transmission Safety of Feedwater Systems

The power plant booster pump serves as the "power source" for the boiler feedwater system. If its transmission components suffer wear due to lubricating oil leakage or contaminant ingress, the outcome can range from a minor shutdown for maintenance to a major accident involving a complete interruption of feedwater supply. The FA1B56-A2-102761A Booster Pump Oil Deflector Ring has become a core spare part for safeguarding the transmission system of the FA1D56A booster pump, thanks to its dual protection performance of "Precise Oil Deflection + Contaminant Isolation." We simultaneously offer complementary parts and customization services to address power plant operation and maintenance challenges.

I. Product Positioning: The "Transmission Protection Shield" for the FA1D56A Booster Pump

The FA1B56-A2-102761A oil deflector ring is not a common accessory; it is a dedicated protection component for the FA1D56A booster pump's transmission system. Precisely installed between the drive-end shaft sleeve and the oil seal sleeve, it works in coordination with the oil seal assembly. On the one hand, it blocks lubricating oil from leaking to the pump exterior, preventing wear of the shaft sleeve and bearings due to insufficient lubrication. On the other hand, it prevents external contaminants such as dust and moisture from entering the oil chamber, protecting precision components like thrust bearings and thrust pads from contamination. It directly influences the booster pump's transmission efficiency and service life.

"We previously experienced lubricating oil leakage due to an aging oil deflector ring, which not only required replacing the thrust bearing but also caused a 2-day shutdown, costing nearly 500,000 kWh in lost generation," an equipment department manager at a thermal power plant admitted. Now, the FA1B56-A2-102761A has become a "mandatory replacement" during maintenance. Its material purity and dimensional accuracy meet original factory standards, allowing for direct adaptation and installation, significantly reducing the risk of failure.

II. Core Application Scenarios: Covering the Entire Life Cycle of the Booster Pump

1. Assembly in New Power Plants: Laying the Foundation for Initial Operation

During the installation phase of the FA1D56A booster pump in a new power plant, this oil deflector ring must be assembled simultaneously with core components such as the impeller, thrust bearing, and mechanical seal. Its precise structural design perfectly matches the clearance between the drive-end shaft sleeve and the oil seal sleeve, establishing a dual "oil deflection + dust prevention" barrier from the start of equipment service, preventing early wear caused by inadequate initial protection. A new power plant reported that after installing this oil deflector ring, the initial inspection cycle of the booster pump extended from 12 months to 18 months, reducing O&M costs by 30%.

2. Scheduled Maintenance: Timely Prevention of Hazard Spread

During annual or quarterly power plant maintenance, technicians focus on inspecting this oil deflector ring. If the ring body shows wear, edge deformation, or corrosion, it must be replaced immediately. Especially when an abnormal drop in oil level is observed via the oil sight gauge, it is highly likely that the oil deflector ring has failed, leading to lubricating oil leakage. Replacing this component at this stage can quickly restore the protection function, preventing consequential damage to thrust pads, oil seal assemblies, etc. One power plant's failure to replace an aging oil deflector ring in time led to thrust bearing wear and doubled maintenance costs, serving as a critical cautionary example in the industry.

3. Emergency Fault Repair: Shortening Downtime

When the booster pump experiences a dual fault of "lubricating oil leakage + contaminant ingress" due to severe oil deflector ring wear, leading to transmission component seizure and shutdown, the FA1B56-A2-102761A is readily available as an emergency spare part. Coupled with the synchronous inspection and repair of the oil seal sleeve and seal casing, replacement and commissioning can typically be completed within 4 hours, shortening the repair time by 60% compared to using non-dedicated oil deflector rings, thus minimizing power generation losses.

III. Core Complementary Spare Parts for the Booster Pump

To meet the power plant demand for "One-Stop Procurement and Coordinated Replacement," we simultaneously supply a full set of booster pump spare parts compatible with the FA1B56-A2-102761A oil deflector ring. All items are stocked in inventory, significantly boosting maintenance efficiency:

| No. | Part Model | Part Name | Applicable Scenario | Complementary Role with the Oil Deflector Ring | Notes |

|---|---|---|---|---|---|

| 1 | FA1D56-03-02 | Seal Retaining Ring | Seal assembly positioning | Fixes the oil seal component position, ensures precise clearance with the oil deflector ring | High-precision machining |

| 2 | FA1D56-03-03 | Seal Casing / Oil Seal Assembly | Shaft end sealing protection | Forms a "Seal + Oil Deflection" combination with the oil deflector ring, enhancing protection | Oil-resistant rubber material |

| 3 | FA1D56-03-18 | Cap Nut | Component fastening | Locks the seal casing and associated parts of the oil deflector ring, prevents loosening | High-strength carbon steel |

| 4 | FA1D56-03-14/19/20 | Stud Bolt | Pump body component connection | Fixes the oil deflector ring's mounting base, ensures positional stability | Anti-corrosion coating treatment |

| 5 | FA1D56-03-21A/24A | Copper Washer / Washer | Bolt sealing | Fills gaps between bolts and components, prevents lubricating oil leakage from the bolt holes | High-pressure sealing |

| 6 | FA1D56-D1-05 | Drive-End Shaft Sleeve | Shaft protection | Directly interacts with the oil deflector ring, reduces shaft body wear | Wear-resistant alloy material |

| 7 | FA1D56-01-05/06/15 | Oil Seal Sleeve | Oil seal positioning | Provides the mounting reference for the oil deflector ring, ensures accurate protection location | Precision tolerance control |

| 8 | FA1D56A-A1GB-10700-00 | Thrust Bearing | Axial force balance | Relies on the oil deflector ring for protection, prevents lubricant loss and contaminant ingress | Low friction coefficient design |

| 9 | FA1D56-01-05/06/15 | Thrust Pad | Transmission load bearing | Failure of the oil deflector ring directly leads to its wear; requires coordinated inspection | Babbitt alloy coating |

| 10 | FA1D56-400/400-00 | Mechanical Seal | Shaft end media sealing | Protects media and lubricating oil separately from the oil deflector ring, ensuring mutual non-interference | Combination seal structure |

IV. Procurement and Service Support: Precise Response to Power Plant Needs

To meet the personalized demands of booster pump operation and maintenance in power plants, our FA1B56-A2-102761A oil deflector ring and complementary spare parts offer multiple guarantees, backed by professional process-by-drawing capabilities. We can optimize the oil deflector ring's material and structure based on measured data from old equipment or specific customization requirements. Our engineers can also provide remote guidance for installation and commissioning.

To check stock or submit customization requests, please contact us directly. We are committed to safeguarding the secure operation of your power plant booster pump.

-

Stop Booster Pump Leaks: Master the HZB253-640-01-05 Oil Flinger Install

Stop lube oil leaks. Learn how to control the HZB253-640-01-05 oil flinger gap, why install direction matters, and how to match its life to your bearing overhaul.02-25

-

Why Re-using the HZB253-640-01-03 Locking Washer Risks Total Booster Pump Failure

Don't let bolts come loose. Learn how to check the HZB253-640-01-03 locking washer for fatigue, why you shouldn't re-use it, and how to install it right.02-04

-

Stop Pump Leaks: A Maintenance Guide for the HZB253-640-01-13 Shaft Sleeve

Prevent booster pump shutdowns. Learn how to spot HZB253-640-01-13 shaft sleeve erosion, pitting, and vibration issues before they ruin your mechanical seals.02-02

-

Stability Principles of the HD452D11 Sliding Bearing Under Extreme Dynamic Loads

Master the HD452D11 sliding bearing. Learn how its oil film and anti-vibration design protect feed pump shafts from wear under high-speed power plant loads.01-31

-

FA1D56A-00-1/4 Gasket: Fitting and Shock Protection for Pump Seal Chambers

Stop leaks in your feed pump seal water chamber. Learn how the FA1D56A-00-1/4 gasket matches your pump to resist pressure jumps and cavitation shocks.01-31