Coal Mill Vibration and Output Drop? The Scraper Device 20MG40.11.07.01J is Your Hidden Culprit

Attention Power Plant Engineers: Do you often face the headache of coal mill bearing vibration suddenly exceeding 0.15 mm/s and output dropping by more than 10% of the design value, yet checks on rollers and bearings reveal no issues?

The root cause might be the often-ignored scraper device. Last year, a 300MW plant's MPS225 coal mill experienced this: after 8 months, vibration spiked to 0.22 mm/s, and output fell from 50 t/h to 41 t/h. Disassembly showed the scraper was worn down to only 40% of its original thickness. Mill rejects (pyrites/stone coal) accumulated in the primary air chamber, even causing slight uneven wear on the Couplings (20MG40.11.02) due to imbalanced stress.

Today, we will guide you on how to precisely diagnose and thoroughly solve this problem, focusing on the Coal Mill Scraper Device (20MG40.11.07.01J). This product not only complies with the DL/T 681-1999 Standard but also works synergistically with peripheral components to eliminate vibration and output issues at the source.

I. 3 Steps to Diagnose Scraper Issues in High-Vibration/Low-Output Mills (Tips Included!)

Many engineers overlook the scraper, but it is the "key to reject discharge." Poor quality scrapers can trigger cascading failures. Here are three quick diagnostic methods, easy enough for even a novice:

1. Check Mill Rejects: Low Discharge, Large Chunks? Scraper is Likely Worn.

- Normal operation: Coal mill rejects discharge around 10-15 kg/h.

- Alarm signal: If discharge suddenly drops below 5 kg/h, or rejects contain stones over 50 mm in diameter, the scraper is failing to sweep.

- Case Example: In the 300MW unit mentioned, the worn-down scraper allowed pyrites to pile up under the grinding bowl, causing load imbalance and increased vibration during bowl rotation. Replacing it with the Coal Mill Scraper Device (20MG40.11.07.01J) immediately solved the poor discharge problem.

2. Measure Parameters: Vibration > 0.15 mm/s + Output Drop > 10%. Check the Scraper First.

Use a vibration meter on the mill bearings. If the vibration exceeds the DL/T 681-1999 standard of 0.15 mm/s, and the actual output is lower than 90% of the design value (e.g., design 55 t/h, actual below 49.5 t/h), immediately stop the mill and open the manhole.

- If the scraper thickness is more than 30% thinner than a new one, or the gap between the scraper and the mill bottom exceeds 10 mm, the scraper is the problem.

3. Inspect Related Components: Uneven Scraper Load? Don't Miss These Parts.

Scraper vibration can also be related to peripheral components:

- If the clearance of the Grinding Roller Thrust Ring (20MG40.11.09.78) exceeds 0.5 mm, it causes uneven roller loading, indirectly increasing the scraper's load.

- Wear on the Axle Sleeve (20MG40.11.09.84) can cause the scraper rotation to jam, also leading to vibration.

- Case Example: The previously mentioned unit was simultaneously fitted with new thrust rings and axle sleeves. Post-replacement, vibration dropped immediately to 0.08 mm/s.

II. Why Choose the 20MG40.11.07.01J Scraper? DL/T 681-1999 Compliance & 3 Anti-Wear Advantages

Substandard scrapers are often non-compliant: low Chromium (Cr) content (below 20%, whereas DL/T 681-1999 requires >= 24%), and low hardness (HRC 45, standard >= 58), resulting in wear-out within 3-4 months.

Our Coal Mill Scraper Device (20MG40.11.07.01J) is manufactured strictly to standard, addressing 3 key pain points:

1. Superior Wear-Resistant Material: 3x Longer Service Life

- Material: Uses KmTBCr26 high-chromium cast iron, with Cr content 24-26% and surface hardness HRC 58-62.

- Standard Compliance: Tested per DL/T 681-1999: In highly abrasive coal types (Ke value 8), after 12 months of continuous operation, the wear amount was only 1.2 mm. This is 3 times longer than common scrapers (which wear 3 mm in 4 months).

- Durability: The scraper body thickness is 12 mm, thicker than the industry standard 10 mm, offering stronger impact resistance against hard foreign materials in the rejects.

2. Optimized Structure: No Jamming, No Coal Leakage

- The 20MG40.11.07.01J scraper is designed with a 15 degree angle to perfectly align with the arc of the mill bottom, ensuring smooth discharge of pyrites.

- The gap between the scraper and the bottom is controlled at 5-8 mm. Paired with our Anti-Wear Plate (20MG40.11.09.71), this prevents coal leakage while minimizing friction with the casing.

- It is secured using Compression Bolts (20MG40.11.08.94J) with an 8.8 grade strength, providing anti-loosening security and eliminating the need for frequent, time-consuming bolt retightening during shutdowns.

3. Strong Compatibility: Seamless Interplay with Mill Components

When replacing the 20MG40.11.07.01J scraper, we recommend checking these related components:

- Medium-Speed Mill Roller Sealing Ring (20MG40.11.09.92): Poor sealing allows dust ingress, accelerating scraper wear.

- Roller Core (20MG40.11.09.94): Roller core runout causes uneven coal flow, increasing scraper load.

- Conical Cover (20MG40.11.08.02J): Deformation of the conical cover affects the air-to-coal flow, indirectly leading to reduced output.

- Case Example: A 600MW plant simultaneously replaced the scraper and these components. The mill output recovered from 52 t/h to 55 t/h, and vibration stabilized at 0.07 mm/s.

III. Installation and Maintenance of 20MG40.11.07.01J: 3 Tips for Extended Service Life

Selecting the right scraper is only half the battle. Correct installation and maintenance are crucial. Here are 3 practical tips from experienced engineers:

1. Installation: Calibrate Clearance and Check Coupling Alignment

- Use a feeler gauge during installation of the 20MG40.11.07.01J to ensure the scraper-to-bottom clearance is 5-8 mm.

- Crucial Step: Simultaneously check the coaxiality of the Coupling (20MG40.11.02); the deviation must not exceed 0.1 mm. Misalignment in the coupling will cause uneven scraper rotation, transmitting vibration to the entire coal mill.

2. Maintenance: Measure Thickness Quarterly & Use Breathers to Prevent Dust

- Thickness Check: Perform a mill shutdown inspection every 3 months. Use calipers to measure scraper thickness. If it falls below 8.4 mm (70% of the original 12 mm thickness), it is time for replacement.

- Dust Prevention: Clear dust from the Roller Breather (20MG40.11.09.01). A blocked breather increases pressure within the roller chamber, affecting coal flow and indirectly increasing the scraper's burden.

3. Emergency Preparedness: Use Spare Scrapers for Quick Replacement

We advise power plants to keep 1-2 sets of our Spare Scraper Blades (20MG40.11.07.01.96J) (the complementary blade for 20MG40.11.07.01J) in stock. In case of sudden scraper failure or breakage, a quick replacement can minimize downtime. Case Example: A plant that suffered a scraper burnout at midnight was able to replace it with a spare unit in 1 hour, avoiding disruption to the morning peak generation schedule.

IV. Conclusion: Solve Vibration/Output Issues with the 20MG40.11.07.01J Scraper

When coal mill vibration spikes and output drops, do not blindly dismantle the grinding rollers—check the scraper first. Substandard scrapers are an "invisible killer."

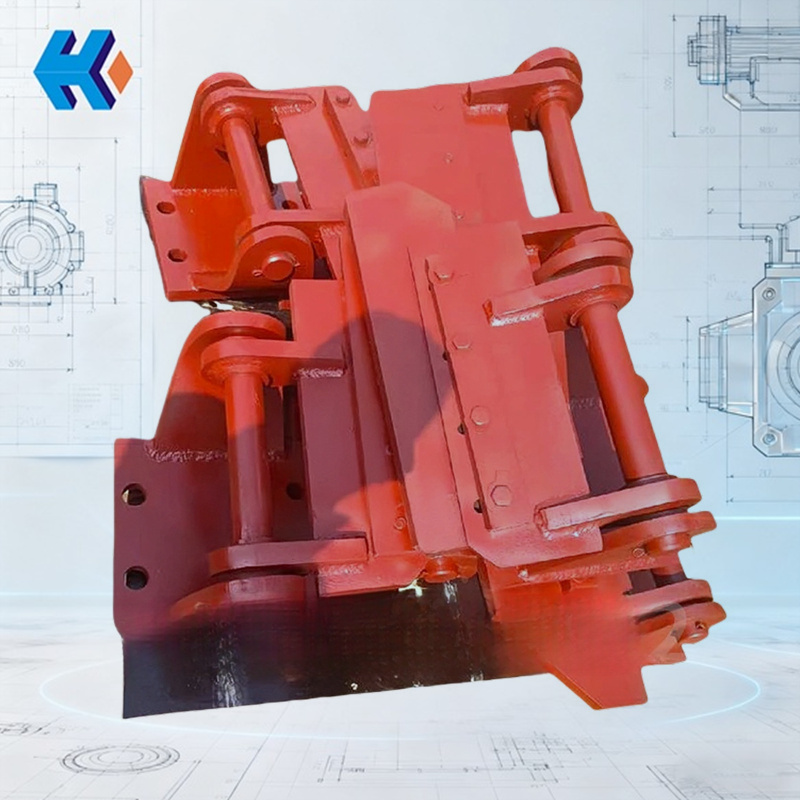

The Coal Mill Scraper Device (20MG40.11.07.01J), manufactured to the DL/T 681-1999 Standard, offers superior wear resistance and adaptability. Paired with complementary components like the Press Frame (20MG40.11.10J) and Back Cover (20MG40.11.09.02J), it provides a comprehensive and lasting solution to your coal mill's operational issues.

HKZX-2025-10-31

-

Stop Booster Pump Leaks: Master the HZB253-640-01-05 Oil Flinger Install

Stop lube oil leaks. Learn how to control the HZB253-640-01-05 oil flinger gap, why install direction matters, and how to match its life to your bearing overhaul.02-25

-

Why Re-using the HZB253-640-01-03 Locking Washer Risks Total Booster Pump Failure

Don't let bolts come loose. Learn how to check the HZB253-640-01-03 locking washer for fatigue, why you shouldn't re-use it, and how to install it right.02-04

-

Stop Pump Leaks: A Maintenance Guide for the HZB253-640-01-13 Shaft Sleeve

Prevent booster pump shutdowns. Learn how to spot HZB253-640-01-13 shaft sleeve erosion, pitting, and vibration issues before they ruin your mechanical seals.02-02

-

Stability Principles of the HD452D11 Sliding Bearing Under Extreme Dynamic Loads

Master the HD452D11 sliding bearing. Learn how its oil film and anti-vibration design protect feed pump shafts from wear under high-speed power plant loads.01-31

-

FA1D56A-00-1/4 Gasket: Fitting and Shock Protection for Pump Seal Chambers

Stop leaks in your feed pump seal water chamber. Learn how the FA1D56A-00-1/4 gasket matches your pump to resist pressure jumps and cavitation shocks.01-31