Balance Drum DG600-240-03-14: A Guide to Feed Water Pump Installation and Axial Force

I. The Thrust Balancer in the Feed Pump

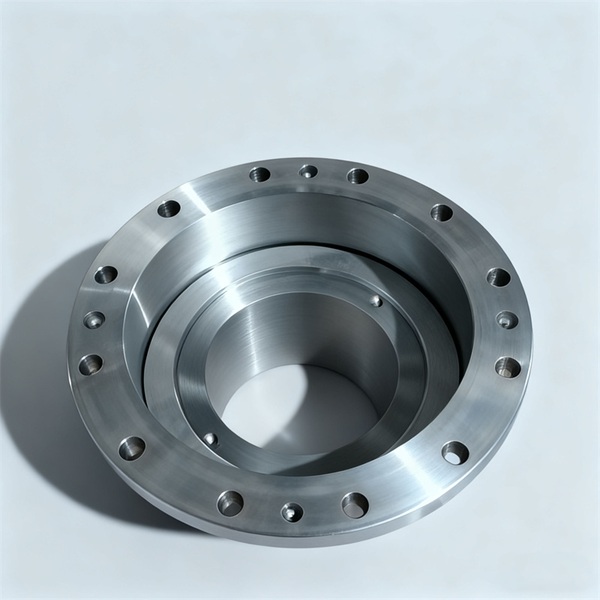

In 300MW and larger thermal power units, the stability of the feedwater system directly affects boiler efficiency and the entire unit's safe output. The DG600-240 electric feed water pump is the main water mover in this system, and the balance drum, specifically the DG600-240-03-14, is the core rotor part that keeps this main unit stable.

Many don't fully grasp what a balance drum does. Simply put, when the feed pump runs, the impellers create an axial hydraulic thrust. Uncontrolled, this force would make the rotor constantly shift, wearing parts and causing vibration. The drum's job is to cancel out this thrust—it's a stabilizer for the rotor, ensuring the equipment runs reliably long-term. Dongfang SRI has years of experience in power plant pump and valve services. Below, we break down the key points of this balance drum, from installation and function to quality.

Core Installation Location: Precision is the Only Way it Works

The DG600-240-03-14 balance drum has strict installation demands; it won't work if just tossed in. It must be precisely fixed onto the high-pressure end of the feed pump main shaft, specifically behind the last-stage impeller. This location is calculated exactly: the final impeller is where high-pressure water exits, so placing the drum here directly leverages the pressure difference to create the balancing force.

A key companion piece during installation is the balance sleeve. The drum and the stationary sleeve form an extremely small clearance. The uniformity of this gap directly impacts balancing performance. Before installing, use a dial gauge to re-check the shaft runout, confirming the drum's outer circle is concentric with the shaft centerline as required. We've seen cases during field overhauls where the drum itself was fine, but poor installation calibration left the gap wide on one side and tight on the other. It quickly leaked upon startup, crippling the balancing function.

How it Works: Using Pressure Difference to Fight Thrust

The working logic of the DG600-240-03-14 is based on fluid mechanics and pressure differential, but it's easy to understand. As the feed pump runs, the high-pressure water discharged by the last impeller enters the small gap formed by the drum and the sleeve. This high-pressure water slowly leaks back to the pump's low-pressure zone through a throttling structure in the gap. In this process, a clear pressure difference forms across the drum: high pressure on the side facing the impeller, low pressure on the other.

This pressure difference creates a reaction force opposite to the impeller's axial thrust. Based on real data, this force cancels out 70% to 85% of the total axial thrust. This drastically lowers the load on the thrust bearing. The bearing, which might have borne massive thrust, now handles only a small residual force. This not only extends bearing life but fundamentally prevents the rotor from shifting due to excessive thrust.

The drum’s condition heavily influences the pump unit. Our technicians found that when the drum wears down, and its radial clearance exceeds 0.675mm, the leakage rate spikes sharply. The pressure difference fails to stabilize, and the balancing function disappears. This causes a chain reaction: thrust pad temperatures soar, and the temperature warning light on the panel flashes often; the rotor vibrates abnormally, and the pump makes loud noises; in the worst case, the feed pump trips immediately, halting the entire unit's operation.

II. Quality Assurance: Strict Control from Material to Process

The drum's working environment is harsh—constant contact with high-temperature, high-pressure steam/water, plus handling friction and vibration. To maintain steady performance here, quality control must run through the entire production process. Dongfang SRI’s DG600-240-03-14 balance drum strictly adheres to the relevant standards, with no slackening at any stage.

Material Choice: Corrosion and Wear Resistance are Basic

The product uses 0Cr13Ni4Mo high-strength corrosion-resistant stainless steel as its raw material. This material has major benefits: first, it resists corrosion in the steam/water environment, avoiding rust after long use; second, its inherent strength supports the forces under high-pressure operation, preventing deformation from pressure fluctuations. Compared to standard stainless steel, 0Cr13Ni4Mo's overall performance is better suited for the feed pump's environment, significantly increasing the drum's service life.

Precision Control: Not Even a Millimeter of Error

The drum's effectiveness heavily depends on precision. Dongfang SRI controls the runout precision of the outer circle to ≤0.015mm—about one-fifth the width of a human hair. This high precision ensures the gap between the drum and the balance sleeve is uniform, preventing localized excessive clearance that causes leaks, and also avoiding a too-small gap that causes friction and seizing.

Beyond outer diameter precision, the drum's end-face flatness and fit tolerance with the main shaft are checked three times or more. After production, every single unit goes through full-size verification using dedicated testing equipment, ensuring that the product delivered to the site is immediately ready for installation without needing secondary machining adjustments.

Process Enhancement: Upgrading Wear Resistance

Good materials and high precision aren't enough. Surface treatment is key to improving wear resistance. This drum uses a dual treatment process: Quenching/Tempering + Surface Hardening. Quenching/tempering optimizes the internal structure, achieving the best balance of strength and toughness. Surface hardening creates a tough protective layer on the outer circular surface, boosting wear resistance. Testing shows its wear resistance is over 30% better than conventionally treated products. Even in long-term, high-intensity operation, it effectively reduces wear and extends overhaul intervals.

III. Full Range of Spares: A One-Stop Solution

Feed pump maintenance often requires several spares to be replaced together for the best outcome. Besides the core DG600-240-03-14 balance drum, Dongfang SRI offers a complete range of critical spares for the DG600-240 series, covering sealing systems, rotor components, stator components, and fastening systems. This gives power plants a one-stop spares solution, eliminating the hassle of sourcing parts from multiple vendors.

| No. | Product Name | Model/Drawing No. |

|---|---|---|

| 1 | O-ring Seal | DG600-240-07-01(11) |

| 2 | Electric Feed Pump Cartridge Seal Kit | DG600-240VM |

| 3 | Thrust Pad | DG600-240-06-00 |

| 4 | Casing Nut (M52×3) | DG600-240-01-02 |

| 5 | Pump Body O-ring Seal | DG600-240 |

| 6 | Secondary Impeller | DG600-240-03-10 |

| 7 | Last Stage Impeller | DG600-240-03-11 |

| 8 | Diffuser Vane | DG600-240-04-13 |

| 9 | Last Stage Diffuser Vane | DG600-240-04-14 |

| 10 | First Stage Impeller | DG600-240(S)-03-09 |

| 11 | O-ring (Same as No. 1) | DG600-240-07-01(11) |

| 12 | Gasket | DG600-240-04-12 |

These complementary spares use the same quality standards as the balance drum, ensuring consistency in material selection and precision control. Using parts from the same series during field overhauls improves assembly compatibility, reducing delays caused by spare parts fitment issues. Whether you are checking seals when replacing the balance drum or fully replacing rotor components during a major overhaul, the efficient synergy provides comprehensive assurance for the stable operation of your feed pump.

HKCYT-2025-11-20

-

Stop Booster Pump Leaks: Master the HZB253-640-01-05 Oil Flinger Install

Stop lube oil leaks. Learn how to control the HZB253-640-01-05 oil flinger gap, why install direction matters, and how to match its life to your bearing overhaul.02-25

-

Why Re-using the HZB253-640-01-03 Locking Washer Risks Total Booster Pump Failure

Don't let bolts come loose. Learn how to check the HZB253-640-01-03 locking washer for fatigue, why you shouldn't re-use it, and how to install it right.02-04

-

Stop Pump Leaks: A Maintenance Guide for the HZB253-640-01-13 Shaft Sleeve

Prevent booster pump shutdowns. Learn how to spot HZB253-640-01-13 shaft sleeve erosion, pitting, and vibration issues before they ruin your mechanical seals.02-02

-

Stability Principles of the HD452D11 Sliding Bearing Under Extreme Dynamic Loads

Master the HD452D11 sliding bearing. Learn how its oil film and anti-vibration design protect feed pump shafts from wear under high-speed power plant loads.01-31

-

FA1D56A-00-1/4 Gasket: Fitting and Shock Protection for Pump Seal Chambers

Stop leaks in your feed pump seal water chamber. Learn how the FA1D56A-00-1/4 gasket matches your pump to resist pressure jumps and cavitation shocks.01-31