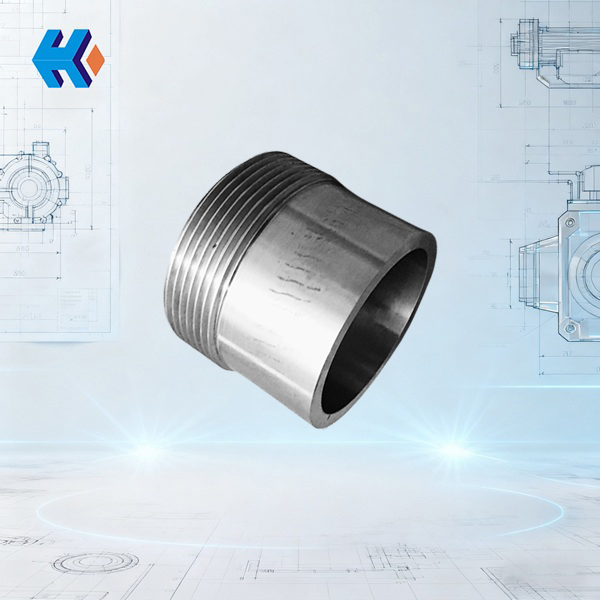

Balance Drum Nut DG600-240-03-19: Left Hand or Right Hand? Don't Mix Them Up!

Every engineer tearing down a DG600-240 electric feedwater pump gets confused by this: Why is the balance drum nut DG600-240-03-19 threaded differently on the drive end versus the non-drive end? You end up holding a lefty and a righty, terrified of putting them in the wrong spot. As a spare parts provider who deals with these power plant fixes all the time, Dongfang SRI is going to lay out exactly why this is done.

I. It's Not Being Picky, It's a Design Forced by Physics

Think about how the feedwater pump runs—if you look from the motor side, the main shaft spins at high speed clockwise. The thread direction of the nut must follow this rotation, or the spinning action will slowly unwind it.

The drive end is the highest stress spot, getting hit by centrifugal force, vibration, and axial thrust all at once. If you used a normal right-hand nut, the main shaft's rotation would constantly try to unscrew it. If the balance drum loses grip, it shifts. Worst case, it flies off the shaft, forcing an immediate pump shutdown. That's why the drive end must use a left-hand thread nut (reverse thread). The tightening direction is opposite to the shaft's rotation. The faster it spins, the tighter it locks itself down—that's dynamic self-locking.

The non-drive end is easier. The forces there are spread out, and there isn't the same huge loosening torque. A standard right-hand thread nut is fine for keeping it locked. The one left, one right design is purely about applying rotation dynamics to keep the pump running safely.

II. Mix-Up = Disaster. Learn the Hard Lessons.

Don't think, I'll just take it out and put it back in the right way. The consequences are much worse. A 300MW power station learned this the hard way: during repair, they swapped the drive end's left-hand nut for a right-hand one. Less than 72 hours later, alarms went off—the thrust bearing temperature shot up to 90°C, the balance drum shifted too much, and shaft vibration hit 10mm/s. When they shut it down immediately, they found the nut had unwound three full turns, and the balance drum had badly ground grooves into the shaft sleeve.

The failure chain is clear: Balance drum fails → Thrust bearing overloads and seizes → Shaft moves violently → Seals break and leak fluid. This forces an unplanned shutdown. The cost for the parts and lost power generation was almost $200,000$, and that's not even counting the messed-up schedules.

III. Dongfang SRI's Fix: Stopping Mistakes Before They Happen

When we make the DG600-240-03-19 nut, we focus on eliminating the fear of messing up. First, the quality is top-notch—forged high-strength alloy steel, heat-treated for toughness, and coated for anti-loosening. It won't crack or rust in the pump's hot, high-pressure environment.

The most practical part is the marking: every single nut face is laser-etched clearly with an L (Left-Hand, Drive End) or R (Right-Hand, Non-Drive End). Don't ignore these letters. During maintenance, nobody has to hunt for the right manual or check a cryptic part number. Just look at the letter, and you know where it goes. This saves time and guarantees no installation error.

IV. DG600-240 Feedwater Pump: All Your Key Spares, One Place

The balance drum nut needs other parts to work right, like seals and bearings. Dongfang SRI supplies the full range of matching spares for the feedwater pump, so you don't have to scramble—all models perfectly match the originals:

| Product Name | Model Specification | Core Purpose |

|---|---|---|

| Asbestos Stainless Steel Gasket | DG600-240-03-08 | Seals joint surfaces; tough and high-temp resistant, stops fluid leaks. |

| O-Ring | DG600-240-07-01(6) | Fits grooves; static seal against corrosion. |

| Centrifugal Pump Snap Ring | DG600-240-07-02(3) | Keeps seals/bearings in place; prevents movement during operation. |

| Thrust Bearing | DG600-240-06-00 | Takes axial force, keeps the shaft from moving too much. |

| Seal Ring Retainer Ring | DG600-240-07-02(4) | Holds the seal ring; stops it from deforming or falling out. |

| Seal Ring Retainer Ring | DG600-240-07-03 | Fits multiple seal spots, boosts leak prevention. |

| Pump Sleeve | DG600-240-04-05 | Protects the pump shaft and seals; helps positioning. |

| Oil Slinger Ring | DG600-240-03-04 | Stops lube oil leaks, blocks dirt from entering the bearing cavity. |

| Water Deflector Ring | DG600-240-04-05 | Blocks moisture from entering equipment, prevents rust. |

| Retaining Ring | DG600-240-07-02(4) | Reinforces seal limits, makes the system more reliable. |

A stable feedwater pump starts with perfectly matched small parts. The one left, one right in the DG600-240-03-19 balance drum nut shows the respect needed for operating conditions. Dongfang SRI doesn't just put these details into the product; we offer full support, from part selection and installation guides to emergency stocking.

Whether you're struggling with the thread direction during an overhaul or need to stock up on spare parts, contact us anytime. Focusing on core power plant spares means less worry and more certainty for every repair job.

HKCYT-2025-12-09

-

Stop Booster Pump Leaks: Master the HZB253-640-01-05 Oil Flinger Install

Stop lube oil leaks. Learn how to control the HZB253-640-01-05 oil flinger gap, why install direction matters, and how to match its life to your bearing overhaul.02-25

-

Why Re-using the HZB253-640-01-03 Locking Washer Risks Total Booster Pump Failure

Don't let bolts come loose. Learn how to check the HZB253-640-01-03 locking washer for fatigue, why you shouldn't re-use it, and how to install it right.02-04

-

Stop Pump Leaks: A Maintenance Guide for the HZB253-640-01-13 Shaft Sleeve

Prevent booster pump shutdowns. Learn how to spot HZB253-640-01-13 shaft sleeve erosion, pitting, and vibration issues before they ruin your mechanical seals.02-02

-

Stability Principles of the HD452D11 Sliding Bearing Under Extreme Dynamic Loads

Master the HD452D11 sliding bearing. Learn how its oil film and anti-vibration design protect feed pump shafts from wear under high-speed power plant loads.01-31

-

FA1D56A-00-1/4 Gasket: Fitting and Shock Protection for Pump Seal Chambers

Stop leaks in your feed pump seal water chamber. Learn how the FA1D56A-00-1/4 gasket matches your pump to resist pressure jumps and cavitation shocks.01-31