Dongfang SRI: Don't Just Patch Up Your Boiler Pipes! Precision Fit Is the Key to Stability

In a thermal power plant's boiler workshop, the scariest sound is a drip. A single leaking pipe fitting can trigger a chain reaction. If an elbow isn't wear-resistant enough, it's gone in six months. If a clearance pipe fits poorly, it cracks during thermal expansion and contraction. These small issues cause unplanned shutdowns in minutes, and a single day of loss can exceed a million dollars.

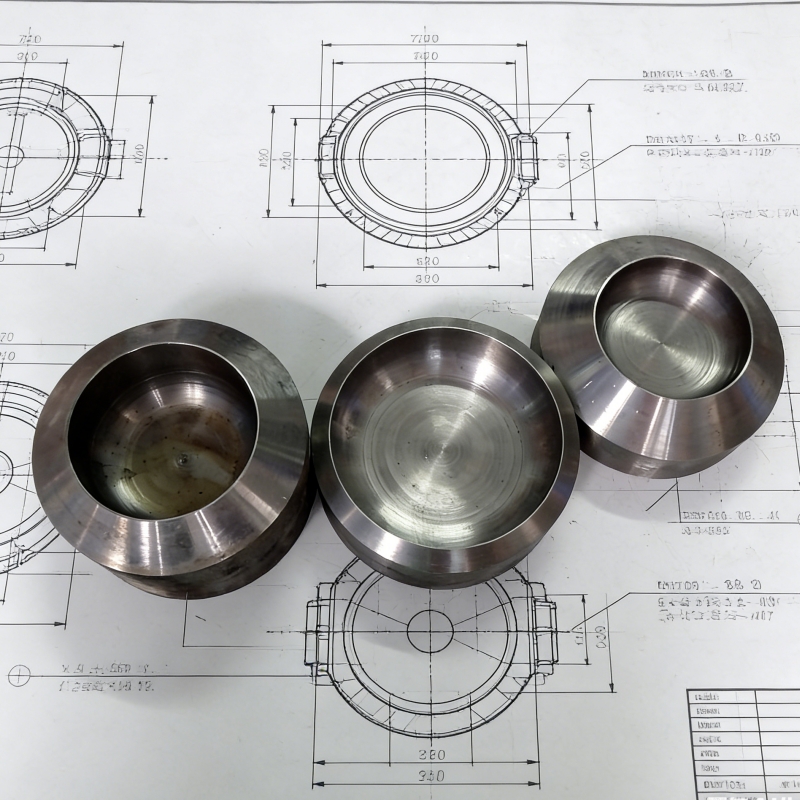

Dongfang SRI has spent over a decade in the power equipment field, focusing on the tough bones of boiler pipe fittings. From the SA-182F91 Handhole Device to SA210C Inner Threaded Boiler Tubes, our entire range is built to the highest industry standards. We pick the best raw materials and lock machining precision down to the micrometer level. Whether you have a 300MW, 600MW, or 1000MW unit, we provide a precision fit so your plant spends less time repairing pipes and more time generating power steadily.

I. Five Core Fittings: Specialized Cures for Leaks and Wear

Pipes in different parts of the boiler have completely different needs. Some must survive 650 degrees Celsius heat, some need high heat transfer, and others must fit perfectly into the furnace structure. We've built a matrix of products where each has its own secret weapon.

1. SA-182F91 Handhole Device: The Sealing King Under High Heat and Pressure

Boiler inspection handholes are disaster zones for high pressure and heat. Standard materials often warp and leak within six months. We use SA-182F91 heat-resistant alloy, which resists creep and maintains its strength even at 650 degrees Celsius. The sealing structure is precision-ground, with a leakage rate less than or equal to 0.01ml/min—10 times stricter than the industry standard. One 600MW plant replaced their handholes with these; a leak point that used to need fixing three times a year hasn't had an issue in two years, saving over 200,000 dollars in labor and downtime.

2. SA210C Inner Threaded Boiler Tube: Fast Heat Transfer and Toughness

Low heat exchange efficiency means ugly electricity bills. Our SA210C tubes aren't smooth inside; they have fine internal threads that increase the heat transfer area by 30 percent and boost exchange efficiency by 15 percent to 20 percent. The SA210C carbon steel has a uniform wall thickness that resists corrosion and wear. While standard pipes thin out in 3 years, these last over 5.

3. SA210-C Furnace Clearance Pipe: Tight Fit Against Impact

For clearance pipes on the front and back walls of the furnace, being off by 1 millimeter is a failure. Non-custom parts either won't fit or will crack during thermal expansion. We customize everything based on the original boiler drawings with a fit precision of plus/minus 0.5mm. The SA210-C material has great high-temperature toughness, so it won't deform or snap even with heavy airflow impact and massive temperature swings.

4. SA-210C Low-Temperature Reheater Elbow: Smooth Flow and Wear Resistance

A rough inner wall in a reheater elbow creates resistance—this wastes energy and lets the medium erode the metal into pits. We use a precision bending process to keep the inner wall smoothness Ra less than or equal to 6.3 micrometers, letting fluid glide through. The SA-210C material stays rock-solid under 10MPa of pressure. We offer 90-degree and right-angle specs to fit any pipe turn.

5. SA210C Expansion and Transition Pipes: Elasticity for Heat Changes

Sudden temperature shifts during boiler startup and shutdown can pull pipes apart, and junctions between different diameters often leak from the impact. Our expansion pipes can stretch or shrink by plus/minus 50mm, absorbing all thermal movement. The transition pipes use a tapered structure for a smooth connection from large to small diameters, cutting fluid resistance. One plant in the south used these to fix loud pipe noise during startup, dropping pipe failure frequency by 70 percent.

II. Hardcore Parameters: Real Data, No Watered-Down Quality

All fittings pass Triple Inspection: raw material analysis, machining precision calibration, and simulated working condition tests. Our key parameters consistently beat industry standards.

| Product Name | Core Material | Operating Temp | Operating Pressure | Advantage Parameter |

|---|---|---|---|---|

| SA-182F91 Handhole Device | SA-182F91 Alloy | 650 C or less | 30MPa or less | Leak rate 0.01ml/min or less, excellent creep resistance |

| SA210C Inner Threaded Tube | SA210C Carbon Steel | 450 C or less | 10MPa or less | Heat transfer boost 15-20%, wear life over 5 years |

| SA210-C Furnace Clearance Pipe | SA210-C Carbon Steel | 450 C or less | 10MPa or less | Fit precision plus/minus 0.5mm, high toughness |

| SA-210C Reheater Elbow | SA-210C Carbon Steel | 450 C or less | 10MPa or less | Inner wall Ra 6.3 micrometers or less, low resistance |

| SA210C Expansion/Transition Pipe | SA210C Carbon Steel | 450 C or less | 10MPa or less | Compensation plus/minus 50mm, tapered low resistance |

III. From Selection to Installation: Total Peace of Mind

The biggest fear is buying the wrong part or installing it incorrectly. We put our service upfront to protect you throughout the process.

1. Engineers Help You Select on Site You don't have to guess parameters from drawings. Our senior engineers will visit your site, check the unit model, and measure conditions to match you with the perfect fitting.

2. Customized for Special Needs Old boiler upgrades or special conditions needing non-standard parts? No problem. Provide the drawings or parameters, and we will machine them to your exact material and size requirements for a perfect fit.

3. Full Installation and Debugging Guidance Worried a bad install will ruin performance? We send technical staff to the site to guide the installation and debug it to the best state. If you have questions later, our engineers are a phone call away with 24-hour response times.

Dongfang SRI: Your Reliable Boiler Butler

Boiler fittings may be small, but they are the foundation of unit stability. Dongfang SRI doesn't do generic parts—we only do precision parts. We don't compete on low prices; we compete on quality. From a single elbow to a full pipe system, we have a reliable solution for you.

Contact us now for a free Boiler Fitting Selection Manual and one-on-one selection service from our engineers. We have plenty of stock, offer nationwide shipping, and can ship the same day for emergency repairs. Choosing Dongfang SRI means choosing less repair, stable machinery, and lower costs. Keep your boiler running efficiently and worry-free.

HKCYT-2025-12-17

-

Stop Booster Pump Leaks: Master the HZB253-640-01-05 Oil Flinger Install

Stop lube oil leaks. Learn how to control the HZB253-640-01-05 oil flinger gap, why install direction matters, and how to match its life to your bearing overhaul.02-25

-

Why Re-using the HZB253-640-01-03 Locking Washer Risks Total Booster Pump Failure

Don't let bolts come loose. Learn how to check the HZB253-640-01-03 locking washer for fatigue, why you shouldn't re-use it, and how to install it right.02-04

-

Stop Pump Leaks: A Maintenance Guide for the HZB253-640-01-13 Shaft Sleeve

Prevent booster pump shutdowns. Learn how to spot HZB253-640-01-13 shaft sleeve erosion, pitting, and vibration issues before they ruin your mechanical seals.02-02

-

Stability Principles of the HD452D11 Sliding Bearing Under Extreme Dynamic Loads

Master the HD452D11 sliding bearing. Learn how its oil film and anti-vibration design protect feed pump shafts from wear under high-speed power plant loads.01-31

-

FA1D56A-00-1/4 Gasket: Fitting and Shock Protection for Pump Seal Chambers

Stop leaks in your feed pump seal water chamber. Learn how the FA1D56A-00-1/4 gasket matches your pump to resist pressure jumps and cavitation shocks.01-31