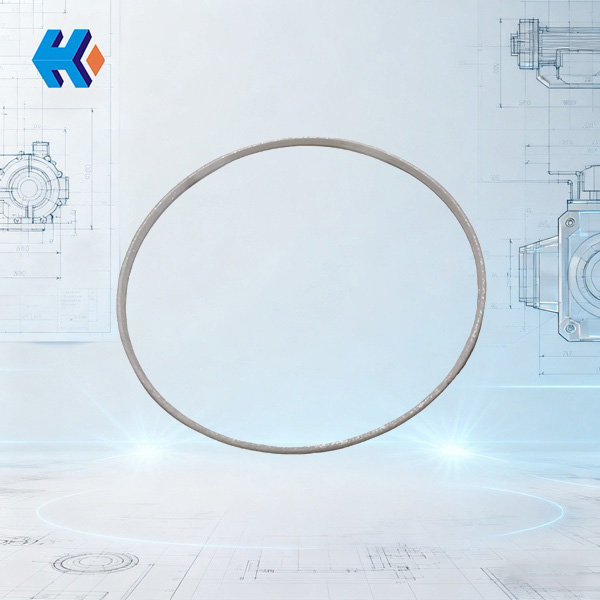

Key Technical Issues in the Application of Feedwater Pump Sealing Ring DG600-240-07-03

1. What primary equipment is the Seal Retaining Ring DG600-240-07-03 compatible with?

This retaining ring is a key sealing component custom-designed specifically for the FK6D32 (DG600-240V) model steam turbine-driven feedwater pump. It is exclusively used within the power station feedwater system for this pump. It is essential that this ring works synergistically with companion components such as the O-ring seal DG600-240-07-01 (11/12) and the pump seal DG600-240-05-11. Together, these parts form a precise pump sealing system, crucial for preventing high-pressure feedwater leakage and ensuring the overall running efficiency of the pump set.

Is your FK6D32 pump due for maintenance? Ensure full compatibility—request our component list today!

2. Why is replacing this retaining ring mandatory during a planned power plant overhaul?

During the planned major overhaul of the FK6D32 steam turbine-driven feedwater pump, the entire sealing system must be thoroughly inspected. The DG600-240-07-03 retaining ring is exposed to continuous high temperatures (normal running temperature plus instantaneous peaks exceeding 300°C) and constant scouring from high-pressure feedwater. Even if the exterior shows no obvious damage, the sealing adherence of the PTFE material will inevitably degrade over its service life. Replacement is necessary to ensure the sealing system is fully restored to its optimal state, preventing the risk of premature leakage failure shortly after the overhaul is completed.

Case Example: A 300MW unit's FK6D32 pump was overhauled, and the old ring was merely cleaned and reused without replacement. Six months later, feedwater leakage occurred, forcing an unplanned shutdown. Inspection revealed microscopic scratches on the inner wall of the old ring. After proper replacement with a new ring, the pump ran smoothly until the next scheduled overhaul cycle (approximately 18 months).

3. What role does this retaining ring play during emergency sealing failure repair?

When the FK6D32 feedwater pump suffers an unexpected leakage shutdown due to seal failure (such as worn O-rings or a deformed retaining ring), the DG600-240-07-03 retaining ring is a crucial emergency spare part. The ring's PTFE material offers an extremely low coefficient of friction, allowing it to rapidly adapt to the sealing surface. This quick sealing integration with the newly replaced O-ring DG600-240-07-01 (12) significantly minimizes the necessary repair time.

Case Example: An FK6D32 pump at a power plant failed due to aging of the retaining ring. The supplier, Dongfang SRI, provided in-stock rings immediately. Maintenance personnel completed the replacement and commissioning in 1.5 hours, cutting the typical repair time by 40% compared to using generic rings, resulting in a saving of approximately 80,000 kWh in lost generation.

4. Is this retaining ring suitable for technical upgrade scenarios of the feedwater pump?

Yes, this ring is highly suitable for technical retrofit scenarios where the power station upgrades its turbine-driven feedwater pump to meet the higher operating parameters of supercritical and ultra-supercritical units. Its PTFE material features superior chemical resistance (withstanding trace corrosive components in feedwater) and exceptional extreme temperature tolerance. This allows it to replace original, standard-material retaining rings, effectively upgrading the sealing system’s compatibility with high-parameter conditions (increased temperature and pressure). This prevents sealing failures that could occur post-retrofit due to inadequate ring performance.

Case Example: A power plant retrofitted its FK6D32 pump to adapt to a 600MW supercritical unit. After installing the DG600-240-07-03 retaining ring, the pump's sealing system was able to stably withstand a pressure of 25 MPa and a feedwater temperature of 280°C, achieving a record of 1 year of continuous operation without any leakage.

5. What components must this ring be paired with? Is purchasing it alone feasible?

It cannot be used alone. It must be paired with other components, including the O-ring seal DG600-240-07-01 (11/12), the pump seal DG600-240-05-11, and O-ring DG600-240-07-01 (12), to establish a complete and functional sealing system. Purchasing it individually is only recommended if you have confirmed that all other complementary components are already on hand and verified to be in good condition.

We advise prioritizing the combination purchase of the "Retaining Ring + Complementary Seals" to guarantee optimal component matching and prevent sealing failures caused by dimensional or material discrepancies between parts.

6. What is the typical service life of this ring, and how far in advance should we stock it?

Under normal operating conditions, the service life of this retaining ring is designed to align with the FK6D32 feedwater pump’s major overhaul cycle (approximately 18–24 months). If the ring is used in the higher-parameter conditions of a supercritical unit, inspection and replacement every 12–15 months is recommended.

Need seals fast? Contact Dongfang SRI now for emergency spares delivery.

HKCYT-2025-10-27

-

Stop Booster Pump Leaks: Master the HZB253-640-01-05 Oil Flinger Install

Stop lube oil leaks. Learn how to control the HZB253-640-01-05 oil flinger gap, why install direction matters, and how to match its life to your bearing overhaul.02-25

-

Why Re-using the HZB253-640-01-03 Locking Washer Risks Total Booster Pump Failure

Don't let bolts come loose. Learn how to check the HZB253-640-01-03 locking washer for fatigue, why you shouldn't re-use it, and how to install it right.02-04

-

Stop Pump Leaks: A Maintenance Guide for the HZB253-640-01-13 Shaft Sleeve

Prevent booster pump shutdowns. Learn how to spot HZB253-640-01-13 shaft sleeve erosion, pitting, and vibration issues before they ruin your mechanical seals.02-02

-

Stability Principles of the HD452D11 Sliding Bearing Under Extreme Dynamic Loads

Master the HD452D11 sliding bearing. Learn how its oil film and anti-vibration design protect feed pump shafts from wear under high-speed power plant loads.01-31

-

FA1D56A-00-1/4 Gasket: Fitting and Shock Protection for Pump Seal Chambers

Stop leaks in your feed pump seal water chamber. Learn how the FA1D56A-00-1/4 gasket matches your pump to resist pressure jumps and cavitation shocks.01-31