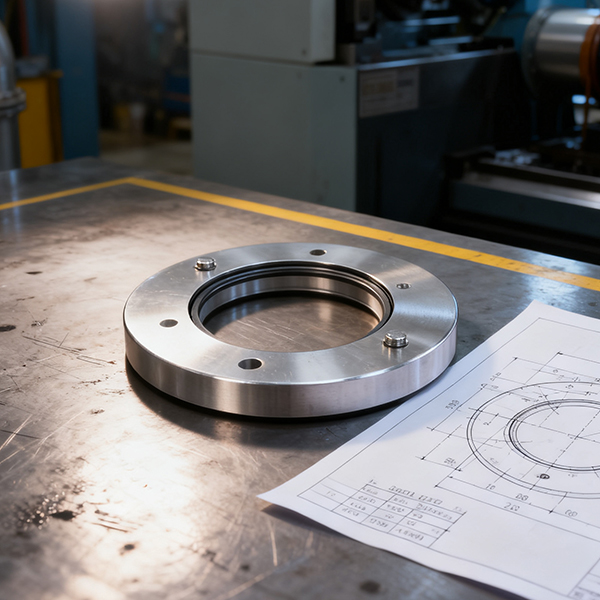

Pump Seal Locating Ring FA1D56-03-02: The Reference Standard for Mechanical Seals

The FA1D56 boiler booster pump is the "pressure guarantor" for the power station's feed water system. The reliability of its shaft seal system directly controls the pump's stable operation. Even a small error in mechanical seal installation precision greatly reduces sealing effectiveness. The FA1D56-03-02 booster pump seal locating ring is the "unsung hero" here—it doesn't seal directly, but it precisely positions and secures the cartridge mechanical seal. This stops axial movement caused by vibration or pressure surges. Many power plants have faced seal leaks caused by deviation in this locating ring, only finding a permanent fix after using original factory spare parts.

Positioning + Securing: The Core Mission

Mechanical seal rotating and stationary rings need extremely high concentricity and perpendicularity to create an even sealing gap and prevent leaks. The FA1D56-03-02 seal locating ring provides the installation datum for the mechanical seal with its accurate inner/outer dimensions and end-face parallelism. This ensures the stationary ring face is strictly perpendicular to the pump shaft axis—the basis for uniform seal face wear and long-term leak-free performance.

The cartridge mechanical seal must be held tightly in the seal chamber. The locating ring uses a flange structure, or a fit with the pump cover, pressed down by fasteners like stud bolt FA1D56-03-19. It "locks" the mechanical seal firmly. It resists axial forces from internal pressure pulsation and external vibration. This prevents the seal assembly from coming loose or shifting—a core performance focus for Dongfang SRI during design.

Material and Process: Built for High-Temp, High-Pressure

The working environment for the FA1D56-03-02 seal locating ring is full of boiler water, high-temp hot water, and steam. The base material is stainless steel. High mechanical strength, easy to machine. It ensures enough rigidity. It won't deform under tightening force, fitting the booster pump's conditions.

Surface treatment is also key. Processes like nickel plating, chrome plating, or electroless nickel phosphorus alloy plating greatly boost corrosion resistance. The smooth, dense plating reduces fitting resistance with the mechanical seal, making installation smoother—a core detail where Dongfang SRI spares outperform non-standard products.

System Synergy: The Essential Companion Parts

The performance of the seal locating ring relies on the whole shaft and seal system working together. It forms the support and protection system for the rotating parts, along with the pump shaft, various shaft sleeves, and fasteners. A failure in any part can cause shaft vibration, leading to premature mechanical seal failure. Below are the core companion parts for the FA1D56 booster pump mechanical seal system. Dongfang SRI offers a one-stop supply with original factory precision match.

| Component Name | Model/Spec | Core Purpose |

|---|---|---|

| Seal Locating Ring | FA1D56-03-02 | Mechanical seal axial positioning, securing, installation datum |

| Pump Shaft | FA1D56A-01 | Power transmission, forms the rotating core |

| Shaft Sleeve | FA1D56-01-15 | Protects pump shaft, isolates friction and corrosion |

| Shaft Sleeve | FA1D56-01-07 | Adapts to different shaft areas, auxiliary sealing and positioning |

| Shaft Sleeve | FA1D56-01-06 | Pump shaft protection, works with mechanical seal for sealing |

| Shaft Sleeve | FA1D56-01-05 | Shaft wear compensation, extends pump shaft lifespan |

| Stud Bolt | FA1D56-03-19 | Presses seal locating ring, secures mechanical seal assembly |

| Shaft Nut | FA1D56-01-08A | Secures rotor components, ensures axial positioning accuracy |

| Locking Washer | FA1D56-01-09 | Prevents shaft nut loosening, boosts securing reliability |

| Shaft Nut | FA1D56-01-12A | Auxiliary axial securing for rotor parts, fits shaft end |

| Cartridge Mechanical Seal | FA1D56A | booster pump core shaft seal component, achieves high-efficiency sealing |

Application and Maintenance: Holding the Seal System's "Baseline"

The FA1D56-03-02 seal locating ring is dedicated to the mechanical seal installation chamber of the FA1D56 series boiler booster pump. It directly determines if the FA1D56A cartridge mechanical seal works properly. If the mechanical seal fails, high-temp, high-pressure boiler water leaks out along the shaft. This loses fluid, washes the bearing housing, causes oil emulsification, and leads to more serious equipment failure.

During plant overhaul, focus on checking the locating ring's end-face parallelism, the integrity of the surface plating, and the fit precision with companion parts. Dongfang SRI suggests checking all associated parts when overhauling the booster pump. Replace worn or deformed parts right away—we supply a full set of original factory spares. This ensures precise fit and avoids secondary failures caused by non-standard parts.

Whether for routine maintenance replacement or emergency repairs, Dongfang SRI can provide the FA1D56-03-02 seal locating ring and companion parts. Ample stock, original factory precision, ship upon order. Our professional technical team can also help check component fit precision. This keeps the booster pump seal system running steady and reduces downtime losses.

HKCYT-2025-12-02

-

Stop Booster Pump Leaks: Master the HZB253-640-01-05 Oil Flinger Install

Stop lube oil leaks. Learn how to control the HZB253-640-01-05 oil flinger gap, why install direction matters, and how to match its life to your bearing overhaul.02-25

-

Why Re-using the HZB253-640-01-03 Locking Washer Risks Total Booster Pump Failure

Don't let bolts come loose. Learn how to check the HZB253-640-01-03 locking washer for fatigue, why you shouldn't re-use it, and how to install it right.02-04

-

Stop Pump Leaks: A Maintenance Guide for the HZB253-640-01-13 Shaft Sleeve

Prevent booster pump shutdowns. Learn how to spot HZB253-640-01-13 shaft sleeve erosion, pitting, and vibration issues before they ruin your mechanical seals.02-02

-

Stability Principles of the HD452D11 Sliding Bearing Under Extreme Dynamic Loads

Master the HD452D11 sliding bearing. Learn how its oil film and anti-vibration design protect feed pump shafts from wear under high-speed power plant loads.01-31

-

FA1D56A-00-1/4 Gasket: Fitting and Shock Protection for Pump Seal Chambers

Stop leaks in your feed pump seal water chamber. Learn how the FA1D56A-00-1/4 gasket matches your pump to resist pressure jumps and cavitation shocks.01-31