Serrated Gasket DG600-240-04-06: The Sealing and Leak-Stopping King of Feed Pumps

https://www.hksri.com/newsinfo/1107156.htmlAt the overhaul site of an FK6D32 steam-driven feed pump, nothing is more annoying than a leaking sealing surface. When you tear it open, the old gasket is either warped from high heat or pitted from corrosion. If you swap it for a cheap, generic gasket, it starts dripping again in less than three months. When this tiny sealing component fails, the cost of an unplanned shutdown can easily hit hundreds of thousands of dollars.

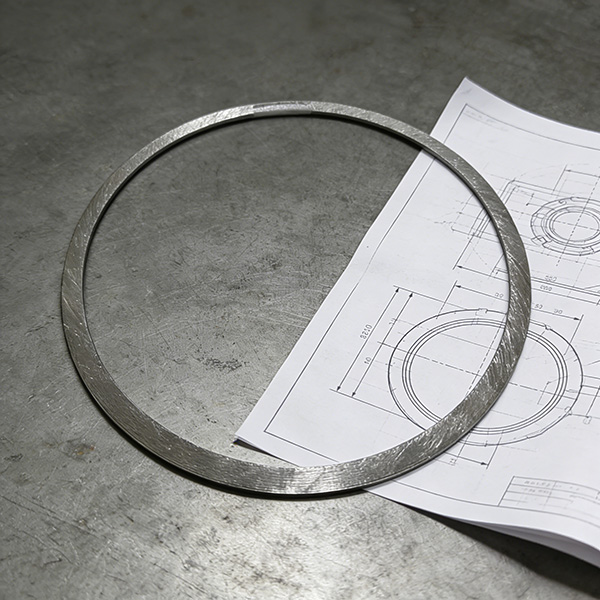

Dongfang SRI custom-built the DG600-240-04-06 serrated gasket to solve this exact problem. Using 1Gr18Ni9Ti stainless steel as the base material, its tooth-like serrated structure bites into the sealing surface. Today, we're breaking down why this part is the Leak-Stopping King.

I. Custom Attributes: A Tailor-Made Fit for the FK6D32

This isn’t a generic gasket; it’s a specialized part built exactly to the maintenance standards of the FK6D32 steam-driven feed pump. Its core job is simple: stay tight against the pump’s sealing surface and lock the high-temperature medium inside. Whether installed at the shaft seal or the inlet/outlet flanges, it stays rock-solid even when the pump is running at full load with pressure peaking at design limits.

When we make this gasket, it goes through four strict checkpoints: the 1Gr18Ni9Ti material undergoes chemical analysis to ensure chromium and nickel levels are perfect; the serrated teeth are ground to be clear and uniform without burrs; the surface smoothness is checked with a micrometer; and finally, we simulate a 600 degrees Celsius environment for leak testing. You can install it directly on-site without any grinding. It also works best as part of a set. Here is the core matching list to ensure you don’t pick the wrong parts during an overhaul:

| Matching Component | Model / Spec | Material / Config | Synergistic Role |

|---|---|---|---|

| Back-up Ring | DG600-240-07-02 | Set of 4 | Limits and fixes the gasket to prevent displacement |

| O-ring | DG600-240-07-01 | Sets of 3, 7, 11, or 13 | Auxiliary static seal to block tiny leaks |

| Disk | DG600-240-04-18 | 2Cr13 Stainless Steel | Enhances surface strength and resists wear |

| Sealing Retainer | DG600-240-07-02 | Set of 3 | Strengthens the structural stability of the seal system |

II. Hardcore Advantages: The Secret to Surviving Heat and Pressure

1. 1Gr18Ni9Ti Material: Survives from -200 to 700 degrees Celsius

When the FK6D32 pump is running, the sealing surface often hits over 400 degrees Celsius. Standard carbon steel gaskets warp quickly, but 1Gr18Ni9Ti austenitic stainless steel stays stable in a wide range from -200 up to 700 degrees Celsius. One plant found that after 11 months of use, our gaskets were still intact and the tooth profile hadn't deformed, while others had already become brittle and cracked.

The corrosion resistance is also top-tier. Feedwater contains trace impurities that eat tiny holes into normal gaskets. The chromium and nickel in our material form an oxide film that blocks corrosion, cutting the risk of seal failure by 60 percent.

2. Precision Serrated Profile: 3 Extra Barriers Over Flat Gaskets

Don't underestimate the teeth. Under bolt tightening pressure, the tips of the teeth undergo slight elastic deformation, embedding themselves like tiny claws into the sealing surface. This fills every microscopic gap and creates multiple sealing barriers. The contact area is 25 percent larger than a flat gasket, distributing pressure more evenly. Even if the sealing surface has minor scratches, it can seal them tight.

We also treat the surface to reduce the bolt torque coefficient by 15 percent, making it easier for mechanics to tighten and preventing biting or jamming during installation.

3. Full-Process Quality Control: Every Batch is Tested

Power plant spares cannot have bad batches. We enforce strict rules: every batch of raw material gets spectral analysis; we use high-precision CNC machines to keep tooth error under 0.02 mm; every finished product is inspected for cracks or burrs; and 10 percent are sampled for high-temp leak tests where the rate must be less than or equal to 0.01 ml/min.

III. Application Scenarios: When and How to Use It

1. FK6D32 Feed Pump Major Overhaul: A Mandatory Replacement

During routine maintenance or a leak repair, this gasket must be replaced. During installation, always wipe the sealing surface clean of oil and grit first. Follow the sequence: Back-up Ring -> O-ring -> Serrated Gasket -> Disk. Tighten bolts evenly in a diagonal pattern and control the pressure according to the manual. Following these steps, many plants report running 12,000 hours without a single leak.

2. Boiler Booster Pump Maintenance: Universal Compatibility

Boiler booster pumps also handle high heat and pressure. As long as the model matches, this gasket works perfectly. One plant used it on a booster pump for a 300MW unit; they went from changing gaskets every 6 months to over 10 months, saving a lot on maintenance costs.

3. Other High-Temp Equipment: Versatile Fit

Beyond feed pumps and booster pumps, this gasket fits other high-temp equipment in the plant, such as steam line flanges. Our engineers can help you match the right type based on your specific equipment parameters to avoid using a part that is too much or not enough for the job.

Dongfang SRI: Not Just Selling Gaskets, But Providing Seal Security

For a power plant, the reliability of a seal directly affects the stability of the entire unit. Dongfang SRI's DG600-240-04-06 serrated gasket is built for one goal: Install it once, stay stable for a year.

If you consult us now, we provide free selection guidance. Our engineers will help you match the best sealing solution based on your unit model and working conditions. For bulk orders, we can even help you plan your inventory to avoid shortages. We have plenty of stock, offer nationwide shipping, and can ship the same day for emergency repairs.

Stop letting low-quality gaskets drag down your maintenance efficiency. Choose Dongfang SRI for fewer replacements, fewer shutdowns, and lower losses. Keep your FK6D32 pump sealed tight and running smooth.

HKCYT-2025-12-18

Previous: Installation Specifications for Servo Valve Gasket TY9100B.1

Next: Why Your Last FK5G32 Overhaul Didn't Last: Let's Talk Radial Bearing

https://www.example.com/news/previous-news-url.html

-

Stop Booster Pump Leaks: Master the HZB253-640-01-05 Oil Flinger Install

Stop lube oil leaks. Learn how to control the HZB253-640-01-05 oil flinger gap, why install direction matters, and how to match its life to your bearing overhaul.02-25

-

Why Re-using the HZB253-640-01-03 Locking Washer Risks Total Booster Pump Failure

Don't let bolts come loose. Learn how to check the HZB253-640-01-03 locking washer for fatigue, why you shouldn't re-use it, and how to install it right.02-04

-

Stop Pump Leaks: A Maintenance Guide for the HZB253-640-01-13 Shaft Sleeve

Prevent booster pump shutdowns. Learn how to spot HZB253-640-01-13 shaft sleeve erosion, pitting, and vibration issues before they ruin your mechanical seals.02-02

-

Stability Principles of the HD452D11 Sliding Bearing Under Extreme Dynamic Loads

Master the HD452D11 sliding bearing. Learn how its oil film and anti-vibration design protect feed pump shafts from wear under high-speed power plant loads.01-31

-

FA1D56A-00-1/4 Gasket: Fitting and Shock Protection for Pump Seal Chambers

Stop leaks in your feed pump seal water chamber. Learn how the FA1D56A-00-1/4 gasket matches your pump to resist pressure jumps and cavitation shocks.01-31